Tomato Processing Market Report by Product Type (Sauces, Paste, Canned Tomatoes, Ketchup, Juice, and Others), Distribution Channel (Business to Business, Retail Market), and Region 2026-2034

Market Overview:

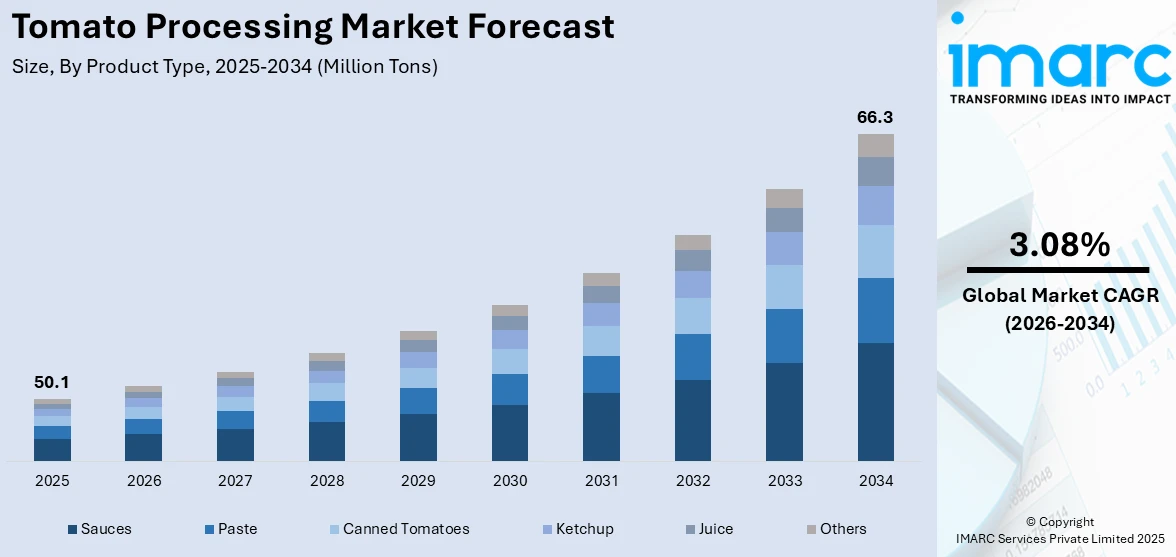

The global tomato processing market size reached 50.1 Million Tons in 2025. Looking forward, IMARC Group expects the market to reach 66.3 Million Tons by 2034, exhibiting a growth rate (CAGR) of 3.08% during 2026-2034. The escalating demand for processed products, such as sauces, pastes, and ketchup, emerging culinary trends, such as the farm-to-table movement and the growing investment in research and development are among the key factors driving the market growth.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2025 |

|

Forecast Years

|

2026-2034

|

|

Historical Years

|

2020-2025

|

| Market Size in 2025 | 50.1 Million Tons |

| Market Forecast in 2034 | 66.3 Million Tons |

| Market Growth Rate (2026-2034) | 3.08% |

Tomato processing is the series of steps taken to transform raw tomatoes into various forms that are easier to store, transport, and use in different recipes. The main aim of this process is to extend the shelf life of tomatoes while preserving their nutritional value, taste, and texture. The most common products resulting from tomato processing are canned tomatoes, tomato sauce, ketchup, and tomato paste. The typical process starts with sorting and washing the fresh tomatoes to remove impurities. Then, they are often blanched to make peeling easier, followed by chopping or crushing. Heat treatment is then applied, often via pasteurization, to kill bacteria and prolong shelf life. Moreover, the processed tomatoes are packed in a sterile environment, usually in cans or jars, to prevent contamination. This industry plays a significant role in food manufacturing, allowing consumers to enjoy tomato-based products year-round and offering a convenient option for quick meal preparation.

To get more information on this market Request Sample

One of the primary market drivers for the tomato processing industry is the rising demand for convenience foods. In today’s fast-paced society, many consumers are seeking quick and easy meal solutions. Processed tomato products, such as sauces, pastes, and ketchup fit this demand perfectly. Therefore, this is significantly supporting the market. Along with this, manufacturers are continuously innovating to offer products that are convenient and healthier, with reduced sodium and sugar levels, to attract a wider consumer base. In addition, demographic changes, including the increasing number of millennials and Gen Z consumers who prefer quick but healthy food options, are pushing demand. Their food choices often include products that are easy to cook and rich in nutrients, making processed tomatoes an attractive option. Apart from this, emerging culinary trends, such as the farm-to-table movement and the increasing popularity of organic, non-GMO products, are also impacting the market. Processors who adapt to these trends by offering specialty products are finding new avenues for growth. Moreover, investment in research and development for creating products with longer shelf life, better nutritional value, and diverse flavor profiles is creating a positive market outlook.

Tomato Processing Market Trends/Drivers:

Health and Nutritional Benefits

The health and nutritional benefits of tomatoes are well-documented, and this is another significant driver for the tomato processing industry. Tomatoes are rich in essential nutrients, such as vitamins A and C, and they are a significant source of lycopene, an antioxidant that has been linked to various health benefits. Additionally, processed tomato products can sometimes be even more beneficial than fresh tomatoes since the processing can increase the bioavailability of certain nutrients. This has led to a surge in consumer interest in processed tomato products that are marketed as being healthful. Brands are increasingly highlighting the nutritional aspects on product labels and through marketing campaigns, attracting consumers who are conscious about their dietary choices. This shift towards health-focused consumption is expected to continue to drive market growth in the tomato processing industry.

Globalization of Cuisine

Globalization has significantly influenced eating habits worldwide, introducing a variety of cuisines to different regions. As a result, dishes that require processed tomato products as a base, such as Italian, Mexican, and Indian cuisines, have gained immense popularity across the globe. This culinary integration creates a strong demand for processed tomato products like sauces, purees, and pastes. In confluence with this, the influence of international travel and the proliferation of global restaurant chains have also familiarized consumers with diverse food cultures. This familiarity drives the demand for the ingredients that make these dishes unique, including processed tomato products. Moreover, the desire for authentic global cuisine is, therefore, a powerful market driver, spurring growth in the tomato processing industry.

Advancements in Processing Technology

In recent years, technological advancements in food processing have significantly impacted the tomato processing industry. Innovations in machinery, such as advanced sorting and grading systems, have streamlined the process, reducing waste and improving yield. Additionally, developments in packaging technology, such as vacuum sealing and the use of preservatives, have extended the shelf life of processed tomato products, making them more appealing to both retailers and consumers. This improves the profitability of manufacturers and makes the products more accessible to a broader market. These advances in technology enable the production of high-quality, consistent, and long-lasting products, which, in turn, instills consumer trust and drives market demand.

Tomato Processing Industry Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the global tomato processing market report, along with forecasts at the global, regional, and country levels for 2026-2034. Our report has categorized the market based on product type and distribution channel.

Breakup by Product Type:

- Sauces

- Food Services Market

- Home Users

- Paste

- Food Services Market

- Home Users

- Canned Tomatoes

- Food Services Market

- Home Users

- Ketchup

- Food Services Market

- Home Users

- Juice

- Food Services Market

- Home Users

- Others

- Food Services Market

- Home Users

Sauces represent the majority of the market share

The report has provided a detailed breakup and analysis of the market based on the product type. This includes sauces (food services market, and home users), paste (food services market, and home users), canned tomatoes (food services market, and home users), ketchup (food services market, and home users), juice (food services market, and home users), and others (food services market, and home users). According to the report, sauces accounted for the largest market share.

The tomato processing industry experiences several market drivers that propel the growth and development of sauces. Additionally, the rising consumer demand for convenience foods significantly influences the rise in production. As more consumers seek easy-to-cook options, ready-made sauces made from tomatoes serve as a staple ingredient. Another significant driver is the global adoption of Western cuisine, which often incorporates tomato-based sauces like ketchup, marinara, and barbecue sauce. Growing health awareness has also made an impact. As consumers become increasingly conscious of their food choices, there's a rising preference for organic and preservative-free sauce options, pushing manufacturers to adapt. Along with this, advances in packaging technology offer extended shelf-life and ease of use, making these products even more attractive to consumers. The impact of e-commerce can't be overlooked either; online platforms make it easier for consumers to access a wide variety of tomato-based sauces. Moreover, seasonality is less of a concern for processed products, enabling year-round availability.

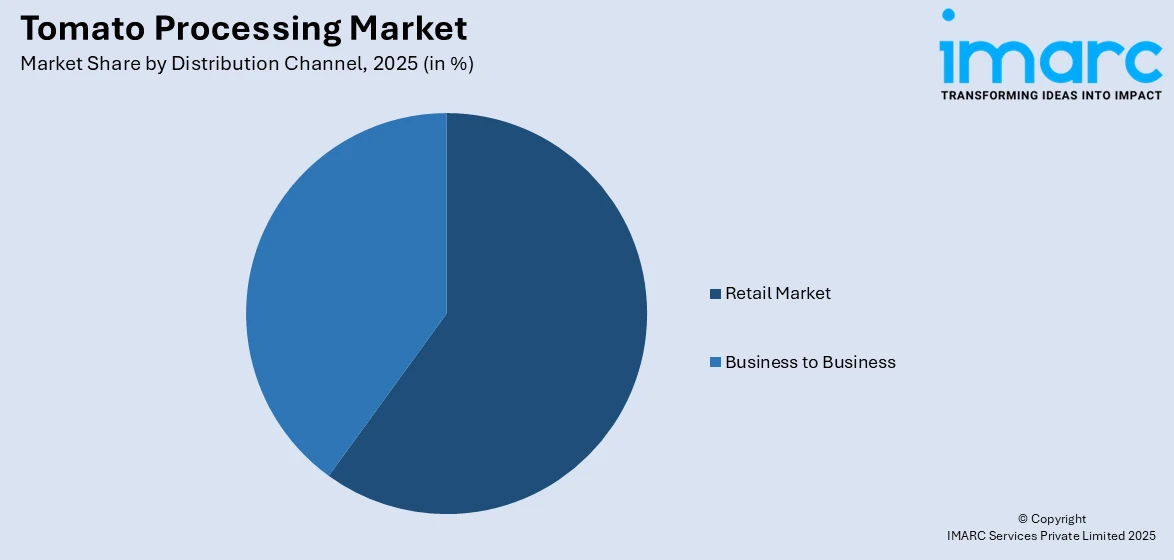

Breakup by Distribution Channel:

Access the comprehensive market breakdown Request Sample

- Business to Business

- Retail Market

- Supermarkets/Hypermarkets

- Specialty Stores

- Convenience Stores

- Online

- Others

Retail market accounts for the majority of the market share

A detailed breakup and analysis of the market based on the distribution channel has also been provided in the report. This includes business to business, and retail market (supermarkets/hypermarkets, specialty stores, convenience stores, online, and others). According to the report, the retail market accounted for the largest market share.

The retail distribution channel plays a pivotal role in shaping the landscape of the tomato processing industry. One of the key market drivers is the escalating demand for packaged and processed tomato products, such as sauces, purees, and ketchups, among consumers who value convenience. Supermarkets and hypermarkets, due to their broad product assortments, serve as key retail outlets that cater to this demand effectively. Along with this, the trend of private labeling has given a boost to retail stores, as they can offer quality products at competitive prices. In addition, the growing influence of organic and clean-label products is also significant. Many retailers are expanding their product lines to include healthier, natural options to cater to consumer consciousness about wellness and nutrition. Apart from this, the burgeoning impact of e-commerce has compelled traditional retailers to adapt by integrating online and offline sales channels, creating an omnichannel experience for consumers. Technological advancements, such as QR codes and contactless payments further ease the shopping experience, promoting retail as a preferred channel. Geographically, the expansion of retail networks into suburban and rural areas is facilitating greater consumer access to processed tomato products.

Breakup by Region:

- North America

- United States

- Canada

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Indonesia

- Others

- Europe

- Germany

- France

- United Kingdom

- Italy

- Spain

- Russia

- Others

- Latin America

- Brazil

- Mexico

- Others

- Middle East and Africa

- Turkey

- Iran

- Others

Europe exhibits a clear dominance, accounting for the largest tomato processing market share

The market research report has also provided a comprehensive analysis of all the major regional markets, which include North America (the United States and Canada); Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, and others); Europe (Germany, France, the United Kingdom, Italy, Spain, Russia, and others); Latin America (Brazil, Mexico, and others); and the Middle East and Africa (Turkey, Iran and others). According to the report, Europe exhibited the largest segment.

The Europe tomato processing industry is influenced by a variety of market drivers that contribute to its sustained growth. One of the main catalysts is the region's robust food culture, which heavily relies on tomato-based products like sauces, pastes, and ketchups. The widespread consumption of Mediterranean cuisine, known for its healthy and flavorful ingredients, including tomatoes, fuels demand. Moreover, European consumers are increasingly health-conscious, showing a growing preference for organic and GMO-free tomato products. This has led manufacturers to adopt sustainable farming practices and cleaner processing methods. Another driver is technological advancements in agriculture and processing, improving yields and reducing waste, thereby making the industry more efficient. The stringent food safety regulations in Europe further ensure high-quality standards, attracting consumer trust and boosting sales. Additionally, the rise of e-commerce has expanded market reach, allowing manufacturers to cater to a broader consumer base. Trade agreements within the European Union facilitate easier cross-border distribution, making products widely accessible. Lastly, ongoing R&D initiatives in the sector aim to develop innovative products that meet evolving consumer preferences, thereby driving demand. In summary, culinary traditions, health consciousness, technological progress, regulatory frameworks, e-commerce, and intra-region trade are key market drivers for the tomato processing industry in Europe.

Competitive Landscape:

The key players are working closely with farmers and suppliers to secure a steady supply of high-quality tomatoes, ensuring the availability of raw materials for their products. They employ advanced processing techniques to convert fresh tomatoes into a range of products, such as tomato paste, canned tomatoes, ketchup, sauces, and more. Along with this, the growing investments in quality control measures to ensure that their tomato products meet safety and taste standards is positively influencing the market. In addition, tomato processing companies often expand their market presence through distribution agreements, partnerships, or entering new geographical markets. This helps them reach a wider audience. Apart from this, there's been a focus on sustainability. Companies are adopting eco-friendly practices, reducing waste, and exploring energy-efficient processing methods to minimize their environmental impact. Furthermore, ongoing research and development efforts to improve production processes is contributing to the market.

The market research report has provided a comprehensive analysis of the competitive landscape in the market. Detailed profiles of all major companies have also been provided. Some of the key players in the market include:

- Conagra Foodservice, Inc

- CONESA Group

- Del Monte Foods, Inc

- Ingomar

- J.G. Boswell Tomato Company

- Kagome Co., Ltd.

- Stanislaus Food Products

- The Campbell's Company

- The Kraft Heinz Company

- The Morning Star Company

Recent Developments:

- In May 2023, Pacific Coast Producers received $890,000 in state funds for climate investment to cut emissions at its Woodland tomato processing plant, which is projected to increase efficiency.

- In February 2022, Olam International announced the news to sell off the northern 15-acre tomato processing portion of the company but keep the remaining 10 acres of the processing facility property for its granulated garlic business.

- In March 2020, NEC Corporation announced the execution of a strategic collaboration contract with Kagome Co., Ltd. to introduce farm management support services for top tomato processing industries using artificial intelligence (AI).

Tomato Processing Market Report Scope:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2025 |

| Historical Period | 2020-2025 |

| Forecast Period | 2026-2034 |

| Units | Billion USD, Million Tons |

| Scope of the Report | Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Predictive Market Assessment:

|

| Product Types Covered |

|

| Distribution Channels Covered |

|

| Regions Covered | North America, Asia Pacific, Europe, Latin America, Middle East and Africa |

| Countries Covered | United States, Canada, China, Japan, India, South Korea, Australia, Indonesia, Germany, France, United Kingdom, Italy, Spain, Russia, Brazil, Mexico, Turkey, Iran |

| Companies Covered | Conagra Foodservice, Inc, CONESA Group, Del Monte Foods, Inc, Ingomar, J.G. Boswell Tomato Company, Kagome Co., Ltd., Stanislaus Food Products, The Campbell's Company, The Kraft Heinz Company, The Morning Star Company, etc. |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the tomato processing market from 2020-2034.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the global tomato processing market.

- The study maps the leading, as well as the fastest-growing, regional markets. It further enables stakeholders to identify the key country-level markets within each region.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the tomato processing industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Key Questions Answered in This Report

The global tomato processing market reached a volume of 50.1 Million Tons in 2025.

We expect the global tomato processing market to exhibit a CAGR of 3.08% during 2026-2034.

The escalating demand for processed tomato products that are generally characterized by a relatively longer shelf life and ease of storage is primarily driving the global tomato processing market.

The sudden outbreak of the COVID-19 pandemic has led to the changing consumer inclination from conventional brick-and-mortar distribution channels towards online retail platforms for purchasing tomato processed products.

Based on the product type, the market has been bifurcated into sauces, paste, canned tomatoes, ketchup, juice, and others. Among these, sauces currently hold the majority of the total market share.

Based on the distribution channel, the global tomato processing market can be segregated into business to business and retail market. Currently, retail market exhibits a clear dominance in the market.

On a regional level, the market has been classified into North America, Asia Pacific, Europe, Latin America, and Middle East and Africa, where Europe currently dominates the global market.

Some of the major players in the global tomato processing market include Conagra Foodservice, Inc, CONESA Group, Del Monte Foods, Inc, Ingomar, J.G. Boswell Tomato Company, Kagome Co., Ltd., Stanislaus Food Products, The Campbell's Company, The Kraft Heinz Company, The Morning Star Company, etc.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)