Aluminum Foil Cost Model: Behind the Roll

What is Aluminum Foil?

Aluminum foil is a flexible, thin, and extremely versatile aluminum sheet that has gained universal application in different industries owing to its superior barrier, thermal, and mechanical characteristics.

Key Applications Across Industries:

Usually made by rolling aluminum slabs or ingots into extremely thin sheets, aluminum foil is 0.006 mm to 0.2 mm thick. Its peculiar combination of properties—light, non-toxic, corrosion-proof, and moldable, enabling it to be used in packaging, insulation, cooking, and industrial applications. In packaging, aluminum foil finds extensive applications to guard food, drinks, and medicines because it is a good barrier against moisture, oxygen, light, and microbes, which results in increased shelf life. At home and in the food service industry, aluminum foil is prized for its conductivity against heat and hence finds extensive use in cooking, baking, and wrapping food. Industrially, it is employed in insulation, electromagnetic shielding, and the manufacture of lithium-ion batteries. Aluminum foil is also recyclable without loss of properties, which meets the increasing demands of sustainability. With improvements in rolling technology and increasing demands for green packaging solutions, the industry for aluminum foil is rapidly changing, being a key material in consumer as well as industrial ecosystems.

What the Expert Says: Market Overview & Growth Drivers

The global aluminum foil market size reached USD 38.2 Billion in 2024. According to IMARC Group, the market is projected to reach USD 53.3 Billion by 2033, at a projected CAGR of 3.57% during 2025-2033. The demand in the global market for aluminum foil is fueled by a number of factors, led significantly by the increasing demand for sustainable packaging solutions.

The food and beverage sector is one of the major drivers, with changing consumer tastes toward convenient eating, packaged foods, and ready-to-eat meals, all of which need consistent barrier protection that aluminum foil ensures. The pharmaceutical sector also largely depends on aluminum foil for blister packaging because it offers tamper resistance and ensures drug stability, particularly in fast-growing emerging markets with healthcare expansion. Another significant impetus is the global concern for sustainability, aluminum foil's ease of recycling and lower carbon footprint compared to plastics make it a value choice over plastics in accordance with regulatory constraints in reducing single-use plastics. Uses in industries are also on the increase, and aluminum foil is being utilized in thermal insulation, electronics, and especially in electric vehicle (EV) batteries, where it is utilized as a current collector in lithium-ion cells. Accelerating urbanization, rising disposable incomes, and expansion in e-commerce are also driving demand for sophisticated packaging solutions, complementing foil consumption further. Additionally, advances in rolling and coating technology are facilitating the manufacturing of thinner, lighter, yet tougher foils, promoting cost-effectiveness and product differentiation. Together, these drivers are emerging as a key material in packaging, energy, and industrial sectors globally for aluminum foil.

Case Study on Cost Model of Aluminum Foil Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale aluminum foil manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed aluminum foil manufacturing plant in India. This plant is designed to produce 10,000 tons of aluminum foil annually.

Manufacturing Flow: The production process of aluminum foil starts with the production of aluminum ingots, which are produced from bauxite via the Bayer process and Hall-Héroult electrolytic reduction process to generate pure aluminum. The ingots are preheated initially and then rolled through a series of rolling mills in what is known as hot rolling. Hot rolling decreases the thickness of the ingot considerably, usually to a few millimeters, and assists in smoothing the metal's grain structure, enhancing its strength and consistency. Once hot rolled, the aluminum is then cold rolled, which means it is passed through increasingly narrower rollers at normal temperatures. Cold rolling is essential in obtaining the ultimate thinness of aluminum foil, usually between 0.006 mm and 0.2 mm, depending on intended usage. At this point, the aluminum might also be annealed, then it is furnaced to a set temperature and cooled to make it more flexible and less prone to cracking, so that it can be shaped or wrapped without breaking. Surface finishing can then occur, in which one or both sides of the foil are polished, matte-finished, or coated, depending on whether it is going into household use, industrial use, or specialized uses like food packaging. Lastly, the aluminum foil is slit to rolls of designated widths and diameters and evaluated for defects and consistency of quality. High-tech manufacturing plants tend to utilize automated control systems for tracking thickness, surface quality, and mechanical properties in real-time. This specific blend of rolling, annealing, and finishing guarantees aluminum foil has the perfect mix of thinness, strength, and flexibility for use in a variety of applications ranging from packaging and insulation to ornamentation and industrial applications.

Get a Tailored Feasibility Report for Your Project Request Sample

Raw Material Required:

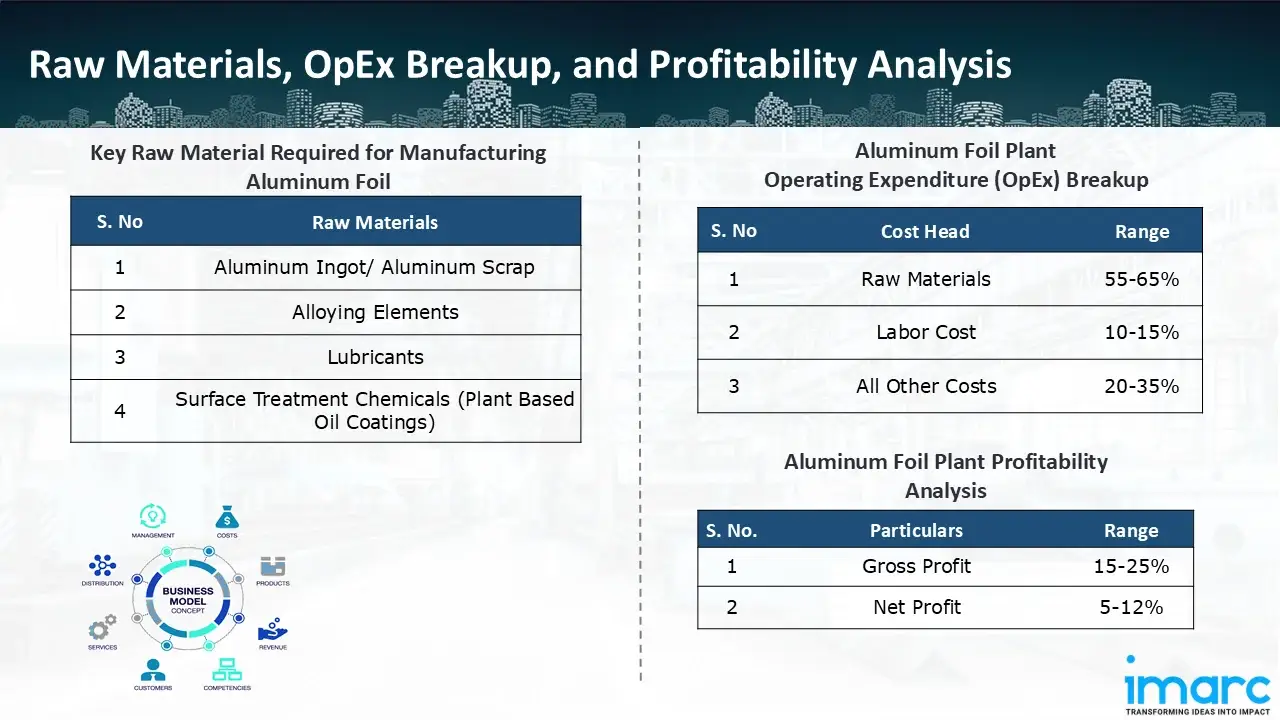

The basic raw materials required for aluminum foil manufacturing include:

- Aluminum Ingot/Aluminum Scrap

- Alloying Elements

- Lubricants

- Surface Treatment Chemicals (Plant Based Oil Coatings)

Machineries Required:

- DC Casting Machine

- Scalper

- Homogenizing Furnace

- Hot Rolling Mill (Reversing Mill or Tandem Mill)

- Reheating Furnace

- Cold Rolling Mill / Foil Rolling Mill (Two-High or Four-High Mill)

- Rolling Oil System

- Annealing Furnace (Batch/ Continuous)

- Slitter/Rewinder Machine

- Edge Trimming Unit

- Lacquering / Coating Line

- Printing Machine

- Embossing Machine (For Decorative Foil)

- Automatic Rewinder & Packaging Line

- Shrink Wrapping / Boxing Unit

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in an aluminum foil manufacturing plant ranges between 55-65%, labor cost ranges between 10% to 15%, and all other costs ranges between 20-35% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 15-25%, and net profit lie between the range of 5-12% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the aluminum foil manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 10,000 tons of aluminum foil annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In June 2025, Hindalco’s Freshwrapp launched a nationwide campaign titled “Bacteria Ki Entry Ko Rokey,” featuring renowned chef and author Vikas Khanna. The campaign introduces Freshwrapp foil wrap’s “Freshlock Shield,” a feature designed to restrict bacteria’s entry into food, thereby promoting food safety, freshness, and hygiene.

- In February 2024, a strategic alliance was established between Lotte Aluminium Materials USA LLC and SMS Group to provide an advanced digitalisation package for Lotte's upcoming greenfield aluminum cathode foil production facility in Elizabethtown, Kentucky. The bundle will assist the facility in establishing new operational guidelines.

- In January 2024, a brand-new aluminum foil production plant has been opened by SRF Limited at Jetapur, Madhya Pradesh, India. This state-of-the-art factory, which complies with good manufacturing practices (GMP), can produce about 20,000 MTPA of rolled aluminum foil.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics:

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish Manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104