Cement Brick Cost Model: Building Efficiency Block by Block

What is Cement Brick?

Cement brick is a precision-engineered masonry unit, a revolutionary improvement over the usual clay brick. Made largely of Portland cement, water, and precisely graded aggregates, which can be sand, stone dust, or even recycled material, these bricks are produced with a high-pressure fusion and compaction process, not firing.

Key Applications Across Industries:

This process, hydraulic pressing, produces a product with very high dimensional consistency and structural strength. The most important advantage of cement bricks is that they have high compressive strength, which makes them most suitable for load-bearing walls, foundations, and multi-story buildings where structural integrity is a premium. In addition, they have better durability, with good resistance against weathering, penetration of water, and sulfate attack, resulting in more durable buildings with lower maintenance costs. Aesthetically, they are hugely versatile; with pigments, they can be manufactured in an enormous range of colors, and their surface can be textured or split-faced to attain different architectural affects, from modern to rural. Although they possess a greater initial thermal conductivity than clay bricks, this can be successfully overcome with external insulation. Overall, the cement brick is a high-performance, long-lasting, and beautiful construction material that is the pillar of contemporary, resilient building works.

What the Expert Says: Market Overview & Growth Drivers

The global cement brick market reached a value of USD 175.68 Billion in 2024. According to IMARC Group, the market is projected to reach USD 263.34 Billion by 2033, at a projected CAGR of 4.1% during 2025-2033. The international market for cement bricks is witnessing dynamic growth, driven by a combination of strong macroeconomic and sector-specific drivers.

The strongest driver is the unrelenting momentum of global urbanization, especially in developing economies in Asia-Pacific, Africa, and Latin America. This city growth generates unprecedented levels of demand for residential, business, and industrial infrastructure, for which cement bricks are an essential building element because they are economical and locally producible. Accompanying this is increasing disposable income, generating demand for better-quality housing and aesthetic personalization, a demand answered by the variety of colors and textures offered by cement bricks. A second key driver is increasing focus on sustainable construction. The sector is making greater use of this with the use of industrial by-products such as fly ash (to produce "fly ash bricks") and recycled aggregates as part of the production process. This not only minimizes the environmental impact by recycling waste but also improves the properties of the product and frequently reduces production costs, fitting in with green building standards and regulatory incentives. Last but not the least, government programs globally, such as high-volume subsidized housing projects, intelligent cities developments, and state-sponsored infrastructure projects, directly spur demand. These factors coupled with the durability inherent in the material and the construction sector's desire for effective, proven building solutions guarantee a favorable and growing worldwide market projection for cement bricks.

Case Study on Cost Model of Cement Brick Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale cement brick manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed cement brick manufacturing plant in India. This plant is designed to manufacture 1.2 million units of cement bricks annually.

Manufacturing Process: Cement brick manufacturing is a precise, mechanized process of converting raw materials to high-strength, uniform masonry units. It starts with the careful selection and batching of raw materials: Ordinary Portland Cement is used as the binding agent, mixed with well-graded aggregates such as sand or stone dust. The all-important ratio of these dry materials is strictly controlled so the final product is strong and durable. Integral water-resistive chemicals or pigments in the case of colored bricks are incorporated at this point. The dry mixture is then passed into a central mixer, into which a predetermined quantity of clean water is added to produce a semi-dry, uniform concrete mixture. This precise water content is essential, it should be low enough to enable demolding without delay, but high enough to ensure correct cement hydration. The blended material is then passed into a hydraulic press machine, the hub of the contemporary procedure. The combination is vibrated and pressed under tremendous pressure in a mold, driving out air spaces and tightly filling the particles. The high-pressure compaction, instead of firing, makes cement bricks particularly strong and dimensionally accurate. The just-created, green bricks are then expelled onto pallets and transported to a curing section. In place of kilns, they are subjected to a controlled curing treatment, usually steam-curing in chambers, to speed the gain in strength using heat and humidity. Once cured, the bricks are warehoused to enable further hardening before packing and shipping for construction.

Get a Tailored Feasibility Report for Your Project Request Sample

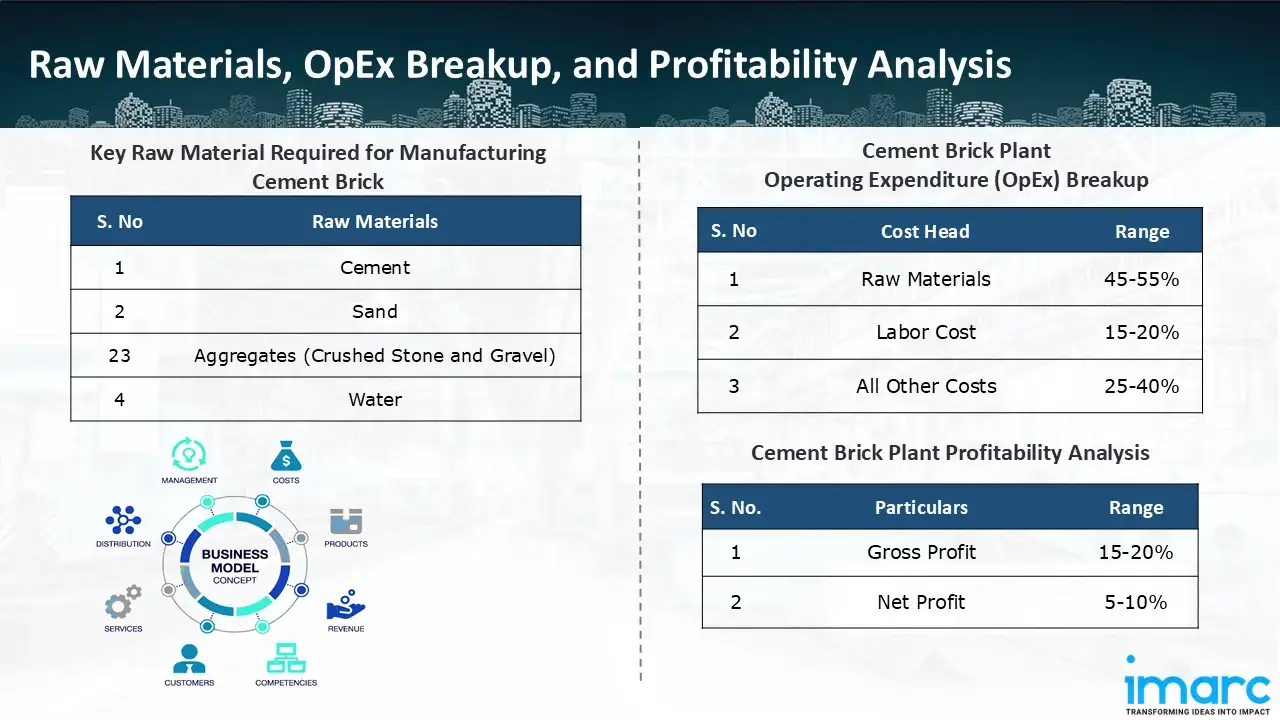

Raw Material Required:

The basic raw materials required for cement brick manufacturing include:

- Cement

- Sand

- Aggregates (Crushed Stone and Gravel)

- Water

Machineries Required:

- Raw Material Handling System (Conveyor Belts, Hoppers and Bins)

- Automatic Mixers

- Automatic Brick Forming Machine (Hydraulic / Electro-Mechanical Press)

- Stacking / Palletizing Machine

- Curing Chambers / Steam Curing System

- Weighing And Storage Bins

- Packaging / Storage Conveyor

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in a cement brick manufacturing plant ranges between 45-55%, labor cost ranges between 15% to 20%, and all other costs ranges between 25-40% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 15-20%, and net profit lie between the range of 5-10% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the cement brick manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 1.2 million units of cement brick annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In December 2024, Material Evolution, a start-up that aims to drastically reduce the carbon footprint of the most widely used building material in the world, announced the opening of its first-of-its-kind ultra-low carbon cement production facility in Wrexham. The facility has been put into service and is currently operating on an industrial scale, making it the largest producer of ultra-low carbon cement in the UK.

- In June 2024, SIAM Cement BigBloc Construction Technologies Pvt Ltd, a joint venture between Thailand's SCG International Corporation Co., Ltd. (SCG International) and Gujarat's BigBloc Construction Ltd., has begun operations in India with the commercial production of its first plant at Kheda, Gujarat. The joint ventures have spent about Rs. 65 crores to establish a 300,000 cubic metre per year capacity project, including India's first AAC Wall Plant, in the Kheda district near Ahmedabad (Gujarat) with the goal of introducing next generation walling solutions for the Indian market.

- In February 2024, Nuvoco Vistas Corp. Ltd.,a large cement group has expanded its operational presence with the inauguration of its second state-of-the-art Ready-mix Concrete Plant (RMX) as Patna-II. Situated strategically at Ranipur Milki Chak, Begampur, bypass, this plant marks Nuvoco's continued commitment for providing top-quality building materials to the Patna region.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.