Drone Cost Model: From Design to Deployment

What is Drone?

A drone, otherwise known as an Unmanned Aerial Vehicle, is a type of aircraft that is flown without the presence of a human pilot on board and can either be remotely controlled or autonomously flown based on predetermined flight paths and onboard sensors. Drones are crafted from lightweight materials such as carbon fiber composites and aluminum to ensure flying efficiency and better battery life.

Key Applications Across Industries:

The individual components comprising a drone include a propulsion system, power source, flight control system, sensors, and communication module. Initially used for military reconnaissance and surveillance, today drones have transformed into multi-taskers that assist many sectors, including agriculture, logistics, filmmaking, infrastructure inspection, disaster management, and environmental monitoring. Increased stability, precision, and efficiency are some of the hallmarks of today's drone technologies, now enhanced by breakthroughs in aerodynamics, AI-based navigation, and electronics miniaturization. Drones are available in multiple configurations: fixed-wing, rotary-wing, and hybrid models, each suited for different applications. For example, rotary-wing drones afford superior maneuverability for short-range tasks, while fixed-wing models offer longer flight times, enabling mapping or surveying over large areas. AI, computer vision, and 5G connectivity have also driven autonomous navigation, real-time data transmissions, and obstacle avoidance capabilities. Increased commercialization and the introduction of consumer-grade drones have increased access and affordability. Nowadays, drones represent a blending of robotics, imaging, and communication technologies, disrupting industries by granting faster, safer, and more efficient aerial operations across a wide range of use cases.

What the Expert Says: Market Overview & Growth Drivers

The global drone market reached a value of USD 30.7 Billion in 2024. According to IMARC Group, the market is projected to reach USD 74.8 Billion by 2033, at a projected CAGR of 10.41% during 2025-2033. The global drone manufacturing market is driven by a confluence of technological, economic, and societal factors that expand the scope of UAV applications. One of the primary drivers is the growing adoption of drones across commercial sectors such as agriculture, logistics, construction, and mining. In agriculture, drones enable precision farming through the gathering of aerial imagery, monitoring crop health, and optimizing irrigation and pesticide use, leading to increased efficiency and cost savings. Similarly, in logistics and e-commerce, drones are being tested and deployed for last-mile delivery, offering rapid, cost-effective, and environmentally sustainable alternatives to traditional methods.

Other key drivers are the development of sensor technologies, artificial intelligence, and automation that improve the accuracy, autonomy, and safety of drones. Real-time data analytics and machine learning algorithms enable drones to perform challenging operations like terrain mapping, inspection of infrastructure, and surveillance with minimum human intervention. Governments and defense organizations also contribute notably to the growth of the market with increased defense spending and modernization programs, whereby drones have become indispensable in surveillance, border monitoring, and tactical missions. Growing demand for aerial data and analytics in energy, telecommunications, environmental management, and other verticals is driving continuous innovation in imaging and communication systems integrated into drones. Regulatory support and the establishment of drone corridors in countries like the U.S., India, and China are encouraging local manufacturing and safe commercial drone operations. Sustainability trends also influence the market because drones result in reduced fuel consumption and lower carbon footprints in logistics and monitoring activities. Overall, innovation, policy support, and industry adoption are coming together to place drone manufacturing among the most dynamic and fast-evolving recent sectors in modern technology.

Case Study on Cost Model of Drone Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium scale drone manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed drone manufacturing plant in India. This plant is designed to manufacture 45,000 units of drones annually.

Manufacturing Process: The manufacturing process of drones is a highly technical and multi-stage procedure that combines mechanical engineering, electronics, software integration, and precision assembly. The process starts with the design and prototyping, where the drone's aerodynamics, weight distribution, and structural strength are determined by engineers while developing 3D models with the use of computer-aided design programs. Then comes the selection of materials, which is usually lightweight and strong, like carbon fiber, reinforced plastic, or aluminum alloys, among others, in order to achieve efficiency in flying and durability. Once the design is finalized, component fabrication begins, involving the production of frames, arms, propellers, and landing gear, often using CNC machining, injection molding, or carbon fiber layup techniques depending on the type of drone being produced. The electronic integration is carried out after the physical structure has been prepared. This includes installing such essential systems as motors, ESCs, flight control units, GPS modules, communication transceivers, and sensors of different kinds-gyroscopes, accelerometers, and barometers-that form the core of the drone in ensuring flight stability and navigation. The battery system, normally a lithium-polymer pack, is integrated to provide power, while wiring and circuit boards are arranged with great care to minimize weight and interference. That will be followed by the software programming and calibration stage, where flight control algorithms, GPS coordinates, and autonomous functions are embedded into the onboard microcontroller. The final step involves quality testing and flight trials to ensure safety, balance, and performance during operational use. Further adjustments are made to achieve an optimized response of controls and endurance. After validation, the drone heads to final assembly and packaging for commercial or industrial use. This manufacturing process harmonizes precision engineering, electronics, and intelligent automation in putting drones together to meet high standards of performance and reliability.

Get a Tailored Feasibility Report for Your Project Request Sample

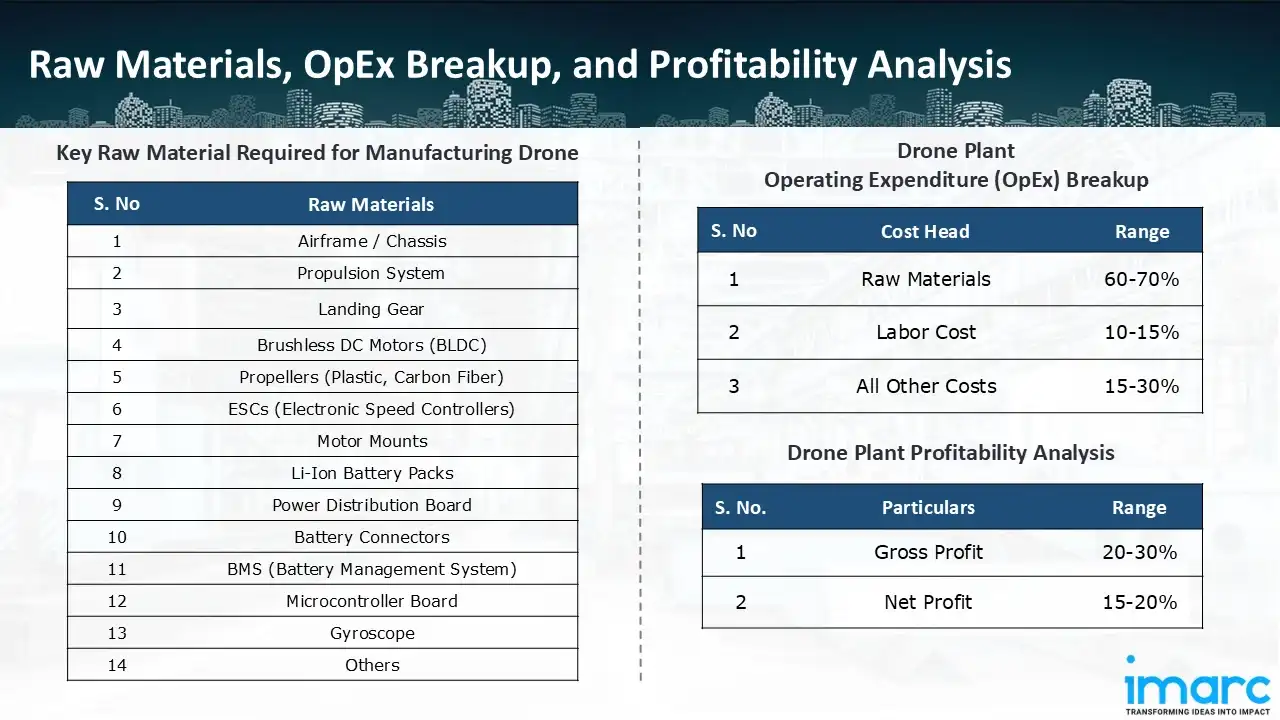

Raw Material Required:

The basic raw materials required for drone manufacturing include:

- Airframe / Chassis

- Propulsion System

- Landing Gear

- Brushless DC Motors (BLDC)

- Propellers (Plastic, Carbon Fiber)

- ESCs (Electronic Speed Controllers)

- Motor Mounts

- Li-Ion Battery Packs

- Power Distribution Board

- Battery Connectors

- BMS (Battery Management System)

- Microcontroller Board

- Gyroscope

- Accelerometer

- Magnetometer

- GPS Module

- Compass

- Ultrasonic Sensors

- Optical Flow Sensors

- Cameras

- Gimbals

- RC Receiver/Transmitter

- Antenna

- Delivery Hooks

- Power Cables

- Signal Wires

- Connectors

- Soldering Supplies

- Vibration Damping Mounts

- Screws

- Nuts

- Bolts

- Standoffs

- Adhesives

- Thread-Lock

- Propeller Guards

- Emergency Parachutes

- LED Indicators

- Wi-Fi/Bluetooth Modules

- Flight Control Software

- Autopilot Firmware

Machineries Required:

- Airframe Manufacturing (Plastic / Carbon Fiber / Aluminum)

- CNC Milling Machine (3–5 Axis)

- Laser Cutting Machine

- Water Jet Cutting Machine

- Injection Molding Machine

- Autoclave / Vacuum Bagging System

- Powder Coating Booth

- Curing Oven

- Sanding / Polishing Machine

- Drill / Tap Machines

- Motor Coil Winding Machine

- Stator & Rotor Press / CNC Jig

- Magnet Insertion Fixture

- Propeller CNC Router

- Injection Molding Machine

- Motor Test Bench / Dynamometer

- Esc Assembly SMT Line

- Esc Test Bench

- SMT Pick-And-Place Machine

- Reflow Oven

- Wave Soldering Machine

- PCB Inspection / AOI System

- Programmer / Firmware Flasher

- Loads Flight Control Firmware

- Wire Cutting & Stripping Machine

- Crimping Machine / Terminal Press

- Vision Inspection Camera / Microscope

- Spot Welding Machine

- Battery Cycler / Charge-Discharge Tester

- BMS Assembly Station

- Thermal Test Chamber

- Assembly Line Workstations / Benches

- Torque-Controlled Screwdrivers (Manual/Electric)

- Robotic Arm

- Cable Routing Fixtures

- Heat Shrink Oven / Gun

- Payload / Camera Mounting Jig

- Battery & Connector Assembly Station

- Motor / Propeller Test Bench

- Flight Simulation Rig Tests

- Vision-Based Motion Calibration Rig

- Battery Load Test Bench

- Environmental Test Chamber

- Foam Cutting Machine / Thermoforming Machine

- Sealing Machine / Vacuum Sealer

- Label Printer / Barcode System

- Final Vision Inspection / QC Station

- Compressed Air System

- Cleanroom / Dust-Free Assembly Area

- ESC Protection System

- Chillers / Temperature Control Units

Techno-Commercial Parameter:

- Capital Expenditure (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth. Furthermore, raw material cost in a drone manufacturing plant ranges between 60-70%, labor cost ranges between 10% to 15%, and all other costs ranges between 15-30% in the proposed plant.

- Profitability Analysis Year on Year Basis: We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins lie between a range of 20-30%, and net profit lie between the range of 15-20% during the income projection years, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the drone manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of manufacturing 45,000 unit of drones annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In October 2025, DJI has revealed a US$ 199 replacement for the Neo selfie drone that it introduced in September of last year. Even while the original was priced for widespread use, it lacked a number of helpful features that the new DJI Neo 2 is introducing, such as gesture controls and the capacity to actively avoid obstacles rather than merely depending on a build that can withstand hits and crashes.

- In February 2025, the Spanish Ministry of Defence (MINISDEF) has given Skydio, the top drone manufacturer in the United States and a global leader in autonomous flying, a contract to provide autonomous small uncrewed aerial systems (sUAS) technology to the Spanish Armed Forces. Skydio will provide Skydio X10D drones under a deal for up to €18 million (US$ 18.7 Million) in collaboration with Paukner Group, a Spanish distributor of defence and security products.

- In March 2024, Autel Robotics Introduces Autel Alpha, a new industrial drone. Autel Alpha is a multipurpose, intelligent industrial drone. It can withstand harsh settings because to its folding construction and IP55 rating. When performing the missions, the integrated RTK dual-antenna system guarantees exact control within millimetres.

Why Choose IMARC?

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104