Integrated Sesame Seed Cost Model: From Raw Sesame to Refined Value

_11zon.webp)

What is Integrated Sesame Seed?

Sesame seeds are one of the oldest oilseed crops known to humankind, prized for their high oil content, distinctive nutty flavor, and valuable nutritional profile. They are composed of approximately 50–60% oil and 20–25% protein, making them an essential raw material for edible oil, bakery, confectionery, and health food industries.

Key Applications Across Industries:

The seeds are also rich in antioxidants such as sesamol and sesamin, which contribute to their oxidative stability and health-promoting properties. Processing of sesame seeds typically involves cleaning, dehulling, roasting, pressing, and solvent extraction, depending on the end-use product. Sesame seeds are widely used in cooking oils, tahini, halva, bakery toppings, and as functional ingredients in nutraceuticals. Their oil exhibits superior shelf stability and high levels of unsaturated fatty acids, making it both a healthy and commercially viable choice. In addition to food, sesame seed oil finds applications in cosmetics and pharmaceuticals due to its moisturizing and antioxidant qualities. The crop offers sustainability benefits as it requires relatively low water compared to other oilseeds, and it can thrive in marginal soils, contributing to climate-resilient agriculture. With growing consumer awareness of plant-based nutrition and clean-label ingredients, the outlook for sesame seed products remains strong, supported by rising global demand for natural, functional, and health-oriented foods.

What the Expert Says: Market Overview & Growth Drivers

The global sesame seed market size reached USD 7.4 Billion in 2024. According to IMARC Group, the market is projected to reach USD 9.1 Billion by 2033, at a projected CAGR of 2.16% during 2025-2033. The sesame seed market is propelled by several perennial demand drivers. Rising consumption of edible oils, particularly those perceived as healthy, underpins steady demand for sesame oil.

Growth in bakery and confectionery industries further boosts sesame seed usage as a key ingredient. Expanding applications in nutraceuticals and dietary supplements, driven by rising health consciousness, also contribute significantly. The increasing use of sesame oil in cosmetics and pharmaceuticals, owing to its antioxidant and skin-friendly properties, represents another stable demand factor. In addition, global trade expansion and urbanization in emerging economies are accelerating demand for value-added sesame-based products. Futuristic trends include the growing adoption of sesame seed oil as a functional food ingredient, the rise of cold-pressed oils in premium consumer segments, and the integration of sesame protein in plant-based food formulations. Competitive advantages include the crop’s adaptability to semi-arid climates and its strong nutritional positioning. However, challenges such as volatile global commodity prices and quality inconsistencies in seed supply remain. Sustainability factors are positive, as sesame cultivation requires minimal irrigation and chemical inputs. The industry has responded by investing in integrated processing plants that ensure value addition, traceability, and consistent quality to meet international standards.

Case Study on Cost Model of Integrated Sesame Seed Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium-to-large-scale integrated sesame seed manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed integrated sesame seed manufacturing plant in Saudi Arabia. This plant is designed to produce 40 tons of tahini, 20 tons of halva, and 100 tons of sesame oil refinery per day.

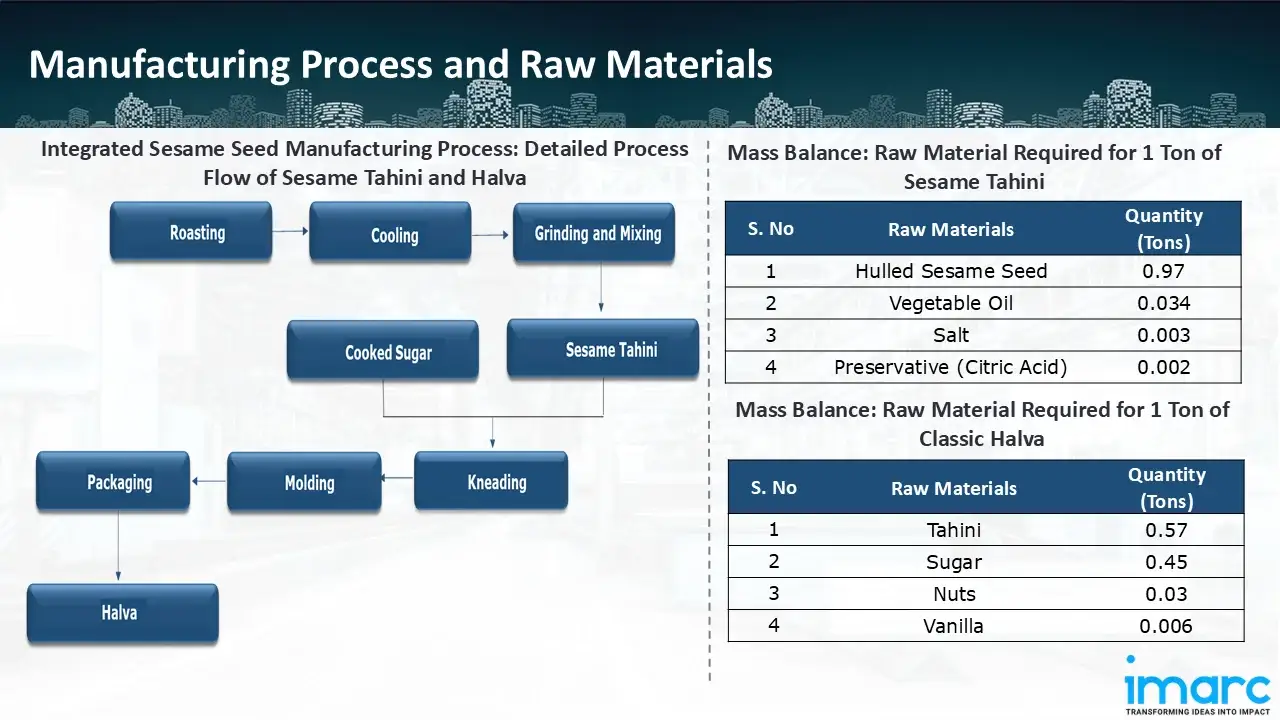

Manufacturing Process: The integrated processing of sesame seeds begins with raw material procurement and cleaning, where harvested seeds are passed through sieves, aspirators, and gravity separators to remove dust, stones, and foreign matter. The cleaned seeds then undergo dehulling, typically through mechanical or wet processes, to separate the seed coat and enhance the quality of oil extraction. In some cases, roasting is carried out to improve flavour and oil yield. Oil extraction can be performed using mechanical expellers or solvent extraction, with the latter employed for maximum recovery. The crude oil obtained is subjected to refining steps, including degumming, neutralization, bleaching, and deodorization, to produce edible-grade sesame oil. Simultaneously, sesame protein-rich cake, obtained as a by-product, is processed into animal feed or food ingredients. The process also includes cleaning and sterilization stages to ensure food safety. Quality control involves physical and chemical testing for oil content, moisture, and impurities, along with microbiological checks. Finished oil is packed in bottles, cans, or drums, while other value-added products like tahini and roasted seeds are sized, packed, and distributed. The integrated facility thus allows to produce edible oil, dehulled seeds, tahini, and protein meal, catering to diverse market needs.

_11zon.webp)

Get a Tailored Feasibility Report for Your Project Request Sample

Mass Balance and Raw Material Required: The primary raw materials used in the sesame oil producing plant are sesame seed and citric acid. For a plant producing 1 ton of sesame oil, 2.15 ton of sesame seed and 0.0003 ton of citric acid are required.

Mass Balance and Raw Material Required: The primary raw materials used in the sesame tahini producing plant are hulled sesame seed, vegetable oil, salt, and preservative (citric acid). For a plant producing 1 ton of sesame tahini, 0.97 ton of hulled sesame seed, 0.034 ton of vegetable oil, 0.003 ton of salt, and 0.002 ton of preservative (citric acid) are required.

Mass Balance and Raw Material Required: The primary raw materials used in the classic halva producing plant are tahini, sugar, nuts, and vanilla. For a plant producing 1 ton of classic halva, 0.57 ton of tahini, 0.45 ton of sugar, 0.03 ton of nuts, and 0.006 ton of vanilla are required.

Techno-Commercial Parameter:

- Capital Investment (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

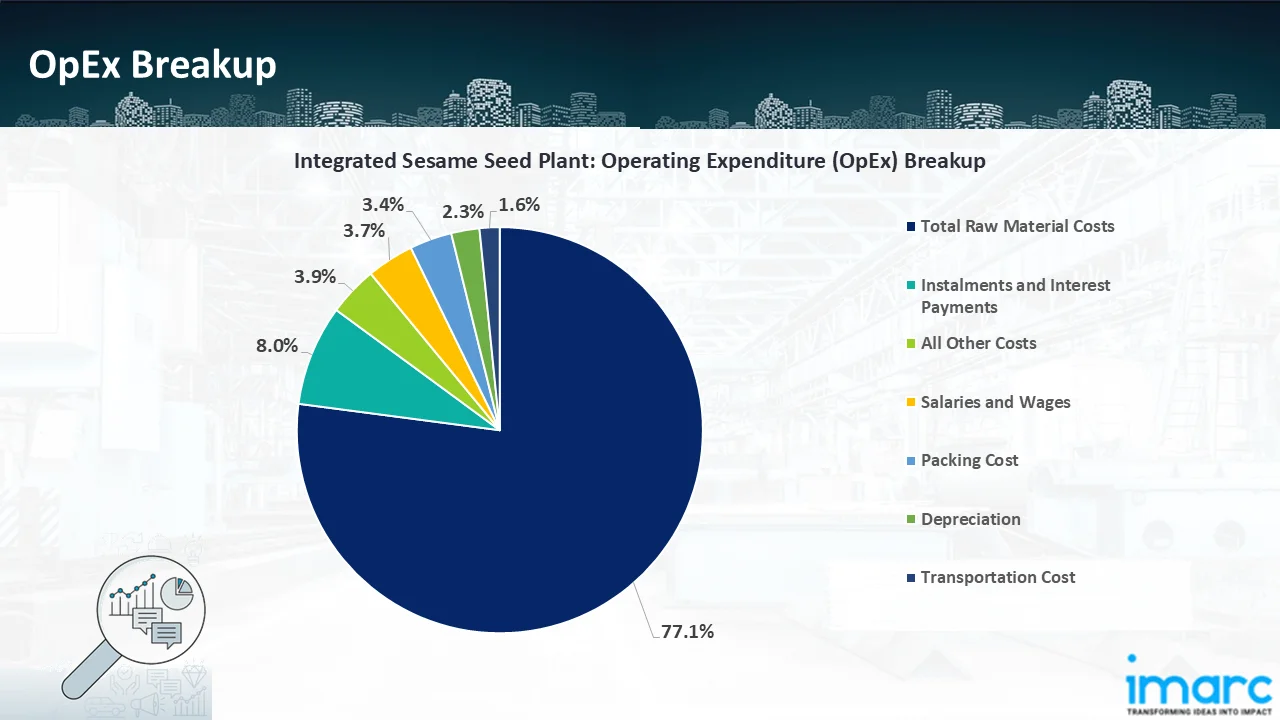

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth.

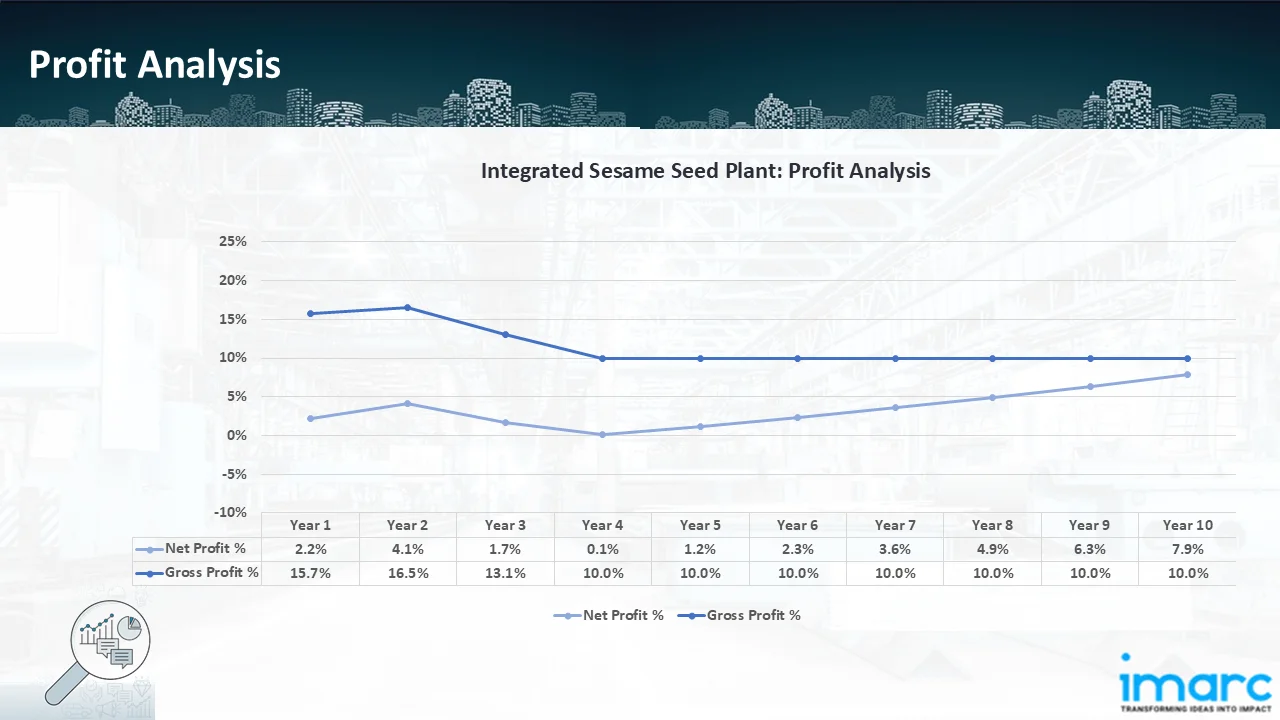

- Profitability Analysis Year on Year Basis: The proposed integrated sesame seed plant, with a capacity of 40 tons of tahini, 20 tons of halva, and 100 tons of sesame oil refinery per day, achieved an impressive revenue of US$ 116.2 million in its first year. We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins decrease from 15.7% to 10.0% by year 10, and net profit rises from 2.2% to 7.9%, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the integrated sesame seed manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of producing 40 tons of tahini, 20 tons of halva, and 100 tons of sesame oil refinery per day, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104