Optimizing Automotive Brake Pad Production: A Comprehensive Cost Analysis

What is Automotive Brake Pad?

In an automotive braking system, brake pads are the most important parts since they are engineered to contact the brake rotor to produce friction, thus stopping or slowing down a vehicle in virtually any driving condition safely and efficiently.

Key Applications Across Industries:

The key way of classifying these pads is according to their material types: low metallic, ceramic, organic, and semi-metallic.

What the Expert Says: Market Overview & Growth Drivers

According to an IMARC study, the global market for automotive brake pads stood at US$ 6.9 Million in 2024 with a CAGR of 0.5% during the years 2019-2024. During the years 2025 to 2033, the market is forecasted to have a CAGR of approximately 4.9% and a projected value of US$ 10.4 Million by the end of 2033.

The factors responsible for driving this market include an increase in electric vehicles and hybrid vehicles that call for special types of brake pads due to their regenerative braking systems. Next, the market for brake pads is growing as more and more consumers realize the importance of road safety and proper vehicle maintenance. The growth in vehicle production within emerging nations and new and advanced manufacturing technology as well as materials science further drives the market. The innovative brake pad solutions are expected to be increasingly in demand as automakers are increasingly looking for strong, lightweight, and environmentally friendly components. This is a growth driver for the market, as the global emphasis on improved vehicle safety and sustainable transportation underlines the crucial role it plays in the changing automotive industry.

Case Study on Cost Model of Automotive Brake Pad Manufacturing Plant:

Objective

One of our clients has requested our assistance in conducting a feasibility study for setting up a medium to large-scale automotive brake pad manufacturing facility in the UAE.

IMARC Approach: Comprehensive Financial Feasibility

We have developed a comprehensive financial model for the plant's setup and operations. The proposed facility is designed with a production capacity of 2,200 units of automotive brake pads per day.

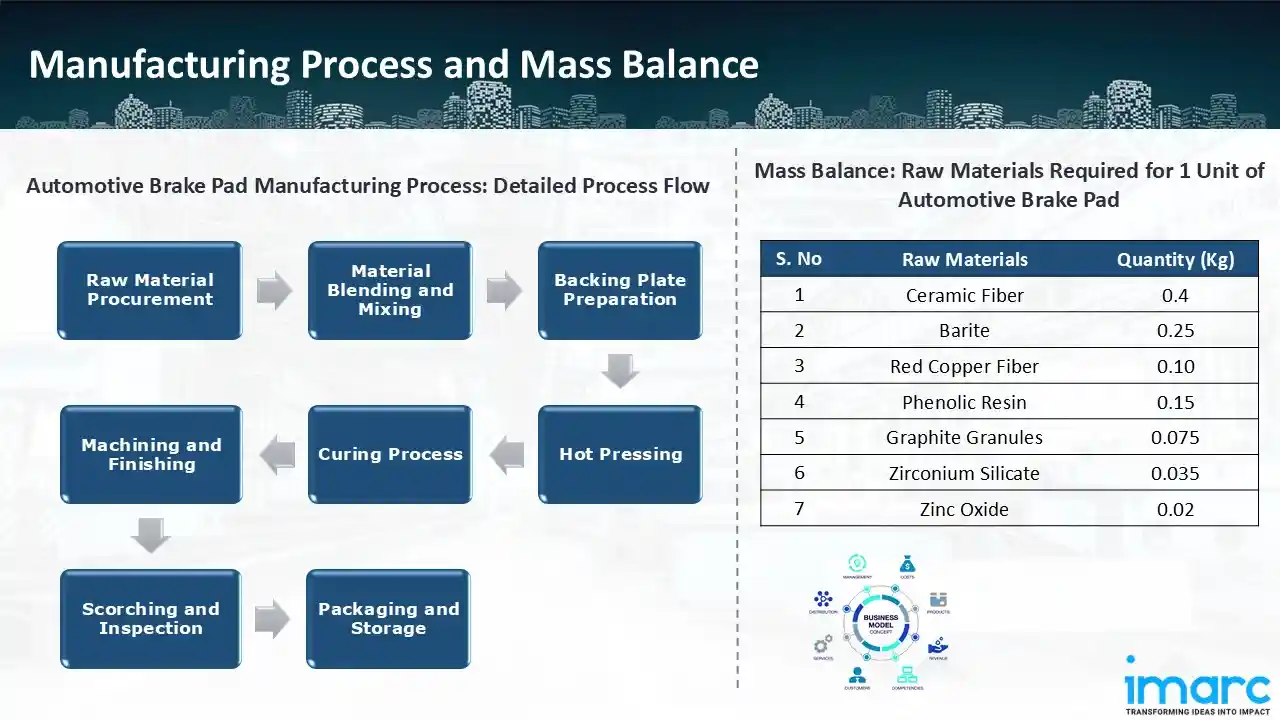

Manufacturing Process: The manufacturing process of automotive brake pads involves several critical steps. First, high-quality raw materials are sourced, such as steel backing plates, ceramic fibres, phenolic resin, Kevlar, and more, and are subjected to stringent quality control. A consistent friction material mix is then produced by carefully blending these ingredients in automated methods. Strong bonding is ensured by cleaning and applying glue to steel backing plates. In the hot-pressing stage, the friction material is moulded into the plates using regulated heat and pressure. To improve structural integrity and heat resistance, it is then cured in ovens. Cured pads are scorched to enhance initial braking performance, grooved to reduce noise, and machined for exact dimensions. Each pad undergoes a thorough inspection process to guarantee compliance with stringent quality standards. Lastly, the pads are sealed in materials that are impervious to moisture and tampering, guaranteeing their endurance throughout transportation and storage. The creation of premium brake pads with dependable performance under trying circumstances is guaranteed by this painstaking procedure.

Get a Tailored Feasibility Report for Your Project Request Sample

Mass Balance and Raw Material Required: The primary raw materials utilized in the automotive brake pad manufacturing plant include ceramic fiber, barite, red copper fiber, phenalic resin, graphite granules, zirconium silicate and zinc oxide. To produce 1 unit of automotive brake pad, 0.4 kg of ceramic fiber, 0.25 kg of barite, 0.10 kg of red copper fiber, 0.15 kg phenolic resin, 0.075 kg of graphite granules, 0.035 kg of zirconium silicate and 0.02 kg of zinc oxide is employed.

List of Machinery

The following equipment was required for the proposed plant:

- Mixer (fr0280) with automatic weight

- Shot blasting machine

- Gluing machine with 5m long air trunk line

- Hot press machine

- Instrumented Oven machine

- Touchscreen oven machine

- Slot and chamfer machine

- 800 mm Electromagnetic grinder

- Powder Coating Spray Line

- Hydraulic Riveting Machine

- X6 UV high-definition inkjet printer

- Film Egde Sealing Machine

- Shrink Film Machine

- Six-station Automatic Weighting Machines

- Mould

Techno-Commercial Parameter:

- Capital Investment (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

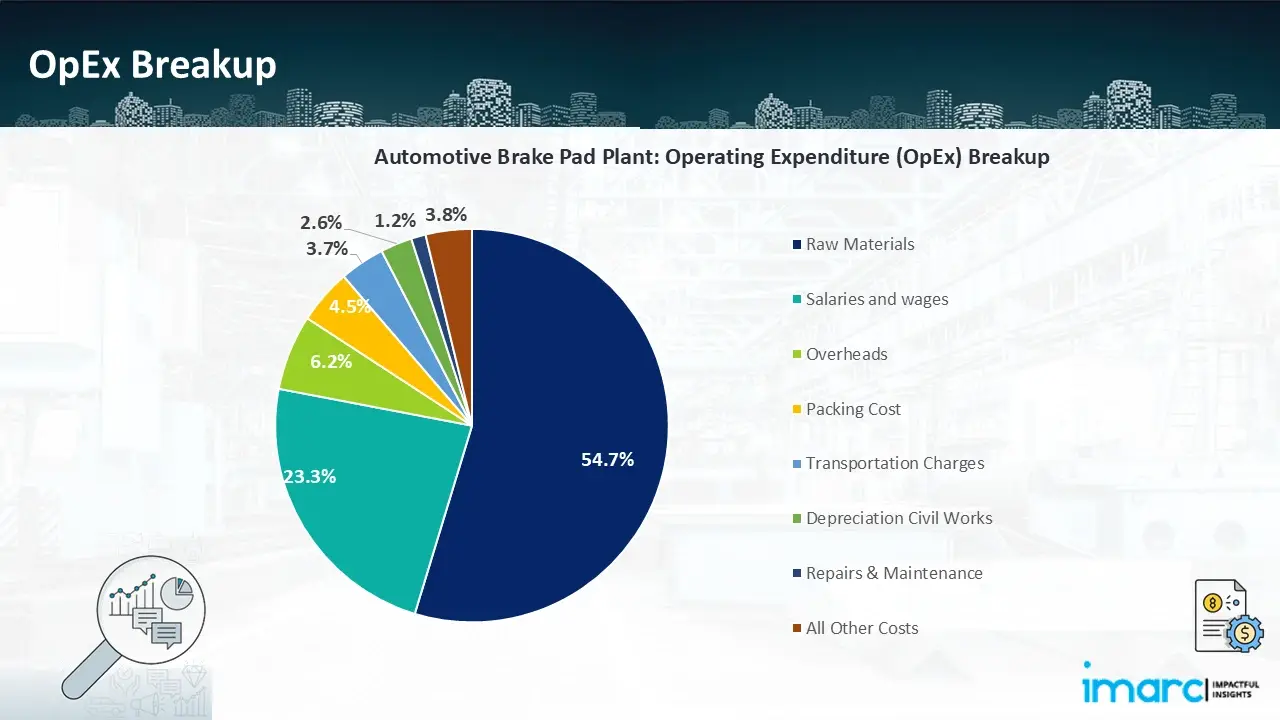

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. OpEx in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth.

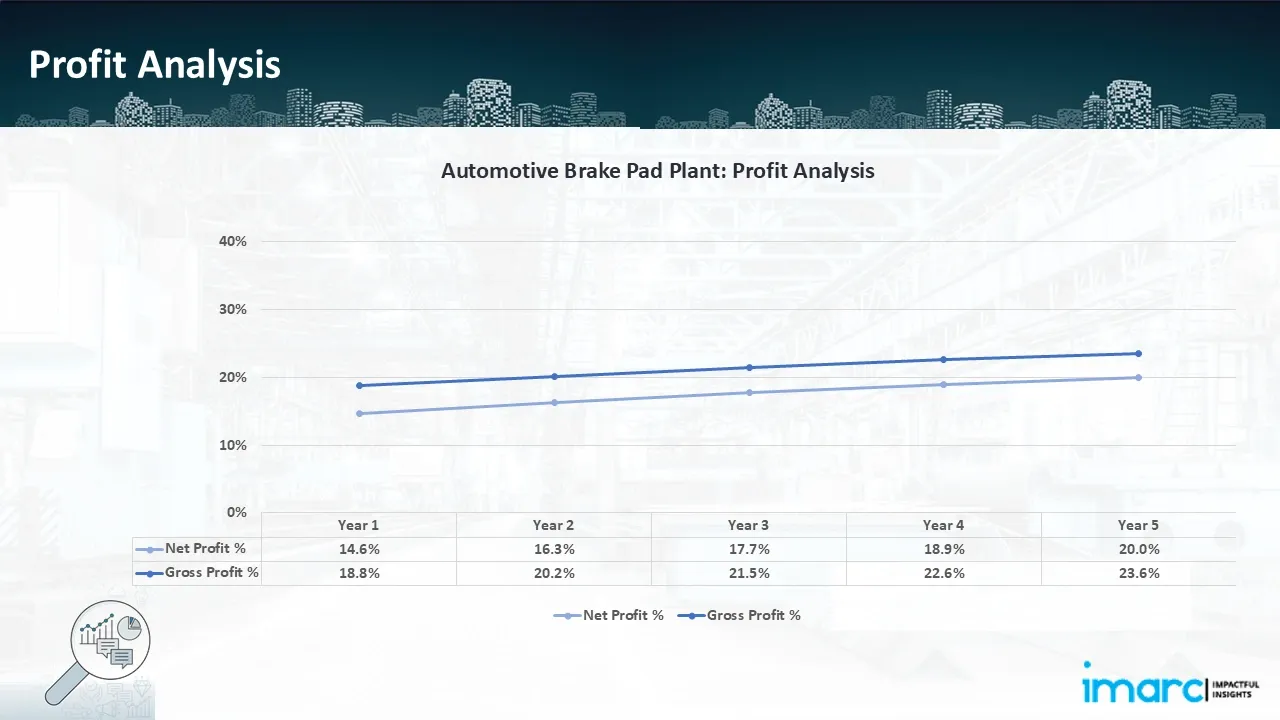

- Profitability Analysis Year on Year Basis: The proposed automotive brake pad plant, with a capacity of 2,200 units of automotive brake pads per day, achieved an impressive revenue of US$ 2.31 million in its first year. We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins improve from 18.8% to 23.6% by year 5, and net profit rise from 14.6% to 20.0%, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

The financial model for the automotive brake pad manufacturing plant was carefully developed to align with the client’s objectives. It includes a detailed analysis of production costs, covering raw materials, manufacturing processes, capital investment, and operational expenses. Designed for a daily output of 2,200 brake pads, the model identifies key cost factors and projects profitability while accounting for market trends, inflation, and potential variations in raw material prices. This tailored model provides actionable insights to support strategic decisions, reflecting our dedication to delivering accurate, client-centered solutions for the sustained success of large-scale manufacturing initiatives.

Latest News and Developments:

- In October 2024, Akebono has added new part numbers to their line of EURO and Severe Duty Ultra-Premium Disc Brake Pads namely SDF1377A, SDF1377B, SDF1399, SDF1699, SDF1790, and SDF2174 are severe duty items; EUR1838 is the EURO.

- In July 2024, Resonac Corporation has created a high-performance disc brake pad composed of non-asbestos friction material (NAO material), which is anticipated to be used in EV electric brake systems. When used on heavy-duty EVs, this recently developed NAO brake pad exhibits tremendous braking power and high abrasion resistance.

- In July 2023, five new ADVICS OE brake pads have been added to the lineup of brake pads offered by ADVICS, a firm that specialises in innovative braking technology and is a part of the AISIN Group of Companies. Through this increase, the current product offering will now cover almost 5 Million vehicles in operation (VIOs).

- In November 2023, Brembo introduced its Copper-Free XTRA brake pad range, which improves performance and sustainability for the environment with Low Met and Ceramic NAO formulas.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Brief List of Our Services: Market Entry and Expansion

- Market Entry and Opportunity Assessment

- Competitive Intelligence and Benchmarking

- Procurement Research

- Pricing and Cost Research

- Sourcing

- Distribution Partner Identification

- Contract Manufacturer Identification

- Regulatory Approvals, and Licensing

- Factory Setup

- Factory Auditing

- Company Incorporation

- Incubation Services

- Recruitment Services

- Marketing and Sales

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104