Transmission Line Tower Cost Model: Powering Connectivity

_11zon.webp)

What is Transmission Line Tower?

Transmission line towers are essential support components of transmission lines installed on overhead to distribute high-voltage electricity over long distances. Towers are made of galvanized steel, primarily, and are designed to tolerate mechanical stress, environmental loads, and electrical safety.

Key Applications Across Industries:

Some of the important characteristics of transmission line towers are high structural strength, corrosion resistance, adaptability for modular design, and high service life. They are normally produced in lattice form (tubular or free-standing towers) or tubular form, with types including suspension towers, tension towers, angle towers, and terminal towers based on use. Production includes precision steel work, galvanizing for rust protection, and strict quality inspection to meet international standards. Uses range from power transmission networks, renewable energy connection, cross-country interconnects, to industrial power distribution. Economically, towers deliver efficient and affordable solutions to big-ticket electrification projects. Sustainability-wise, towers are completely recyclable, and innovations in design are cutting the amount of material needed while enhancing load efficiency. The outlook is rosy for the future, as increasing renewable energy infrastructure, smart grids, and rural electrification projects around the world continue to fuel demand.

What the Expert Says: Market Overview & Growth Drivers

India transmission line market size reached USD 9.6 Billion in 2024. According to IMARC Group, the market is projected to reach USD 12.7 Billion by 2033, at a projected CAGR of 3.10% during 2025-2033. The market for transmission line towers is driven by a fast pace of growth in electricity consumption, led by urbanization, industrialization, and digitalization.

The most significant driver is the world's transition toward renewable energy, with integration of wind, solar, and hydro power projects into the grid necessitating large-scale transmission infrastructure. Electrification initiatives promoted by governments in developing nations also drive growth. Rising cross-border electricity exchange and interconnect schemes also contribute to increasing tower demand. Another impetus is the replacement and modernization of old power grids, particularly in North America and Europe. Trends in the future are modular tower constructions for quicker installation, light materials to save on logistics, and integration of digital twins for predictive maintenance. Moreover, advancements in corrosion-proof coatings and high-strength steel will help increase tower efficiency and longevity. Competitive benefits include high scalability, strong lifecycle performance, and recyclability. Nevertheless, the sector is confronted with challenges like volatile steel prices and delay in projects due to regulatory and environmental permits. Sustainability is a major concern, with industry strategies biased towards material optimization, more eco-friendly galvanization practices, and lifecycle carbon footprint minimization.

Case Study on Cost Model of Transmission Line Tower Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium-scale transmission line tower manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed transmission line tower manufacturing plant in India. This plant is designed to produce 150,000 tons of rolling mill, and 60,000 tons of initial tower annually.

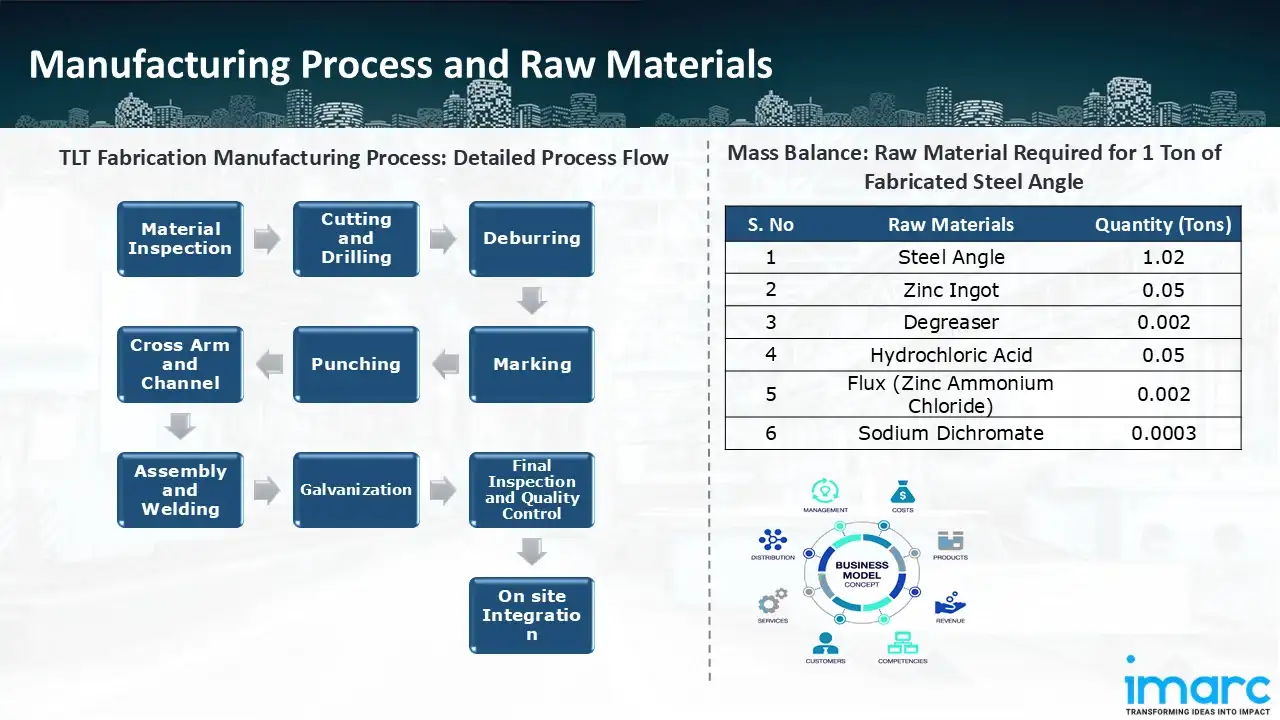

Manufacturing Process: Production of transmission line towers is a well-organized process that converts raw steel billets into precision-engineered, rugged pieces for field assembly. It starts with procurement and inspection of high-strength steel billets, which are reheated to attain malleability prior to roughing and intermediate rolling to form them into initial profiles. Subsequent finishing in the finishing mill provides precise dimensions, followed by controlled cooling for retaining strength and slow straightening to eliminate distortions. Pieces are subsequently cut to specified lengths with hot saws and run through sophisticated CNC and hydraulic equipment for drilling, punching, milling, bending, notching, and marking, achieving precision within ±1mm. Later welding and bolting create sub-assemblies such as legs, bracings, and cross-arms with robotic welding stations contributing consistent strength at key areas. Surface preparation processes of degreasing, pickling, washing, and fluxing are followed by hot dip galvanizing into molten zinc that shields parts against corrosion and increases durability. Quality control is continuous with dimensional verifications, weld strength testing, and coating checks for conformance to standards. Following approval, galvanized parts are bundled, packaged with fittings, and shipped for on-site construction. This end-to-end process ensures transmission towers have high mechanical, structural, and durability standards for efficient power infrastructure.

_11zon.webp)

Mass Balance and Raw Material Required: The primary raw materials used in the steel angle producing plant is mild steel billet. For a plant producing 1 ton of steel angle, 1.05 tons of mild stell billet (IS 2830) is required.

The primary raw materials used in the fabricated steel angle producing plant are steel angle, zinc ingot, degreaser, hydrochloric acid, flux, and sodium dichromate. For a plant producing 1 ton of fabricated steel angle, 1.02 tons of steel angle, 0.05 ton of zinc ingot, 0.002 ton of degreaser, 0.05 ton of hydrochloric acid, 0.002 ton of flux, and 0.0003 ton of sodium dichromate are required.

Techno-Commercial Parameter:

- Capital Investment (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

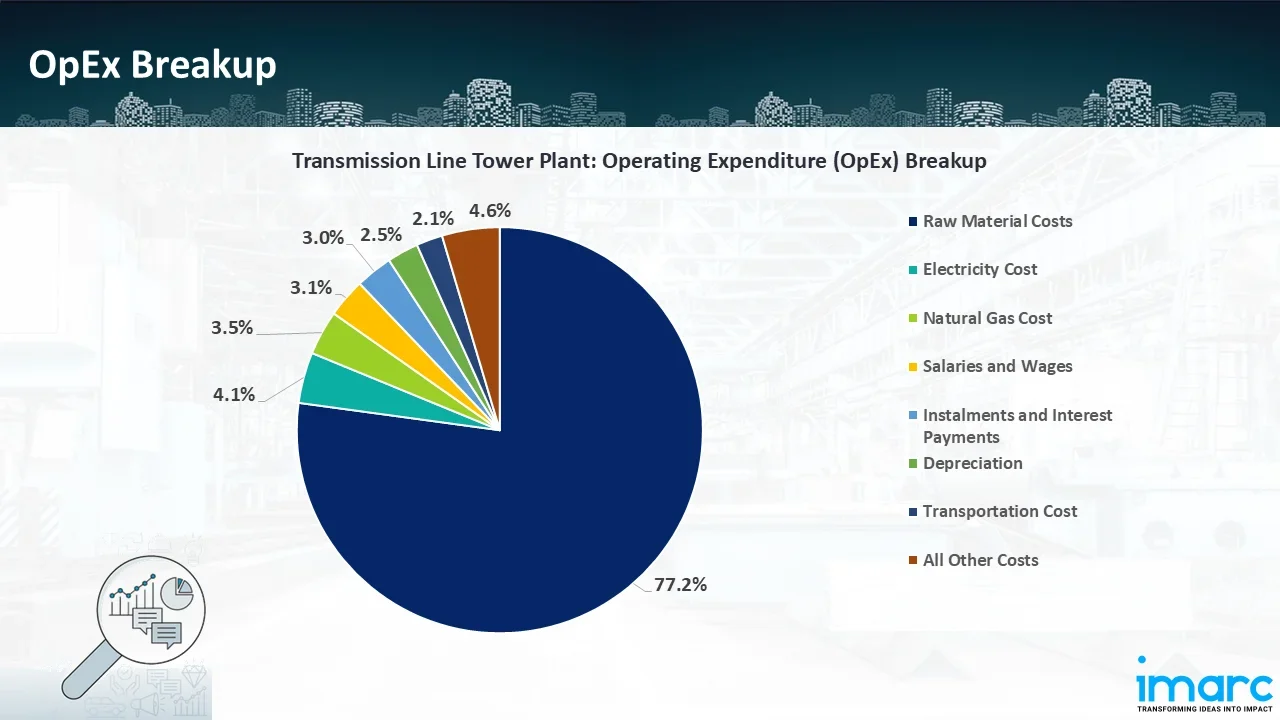

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth.

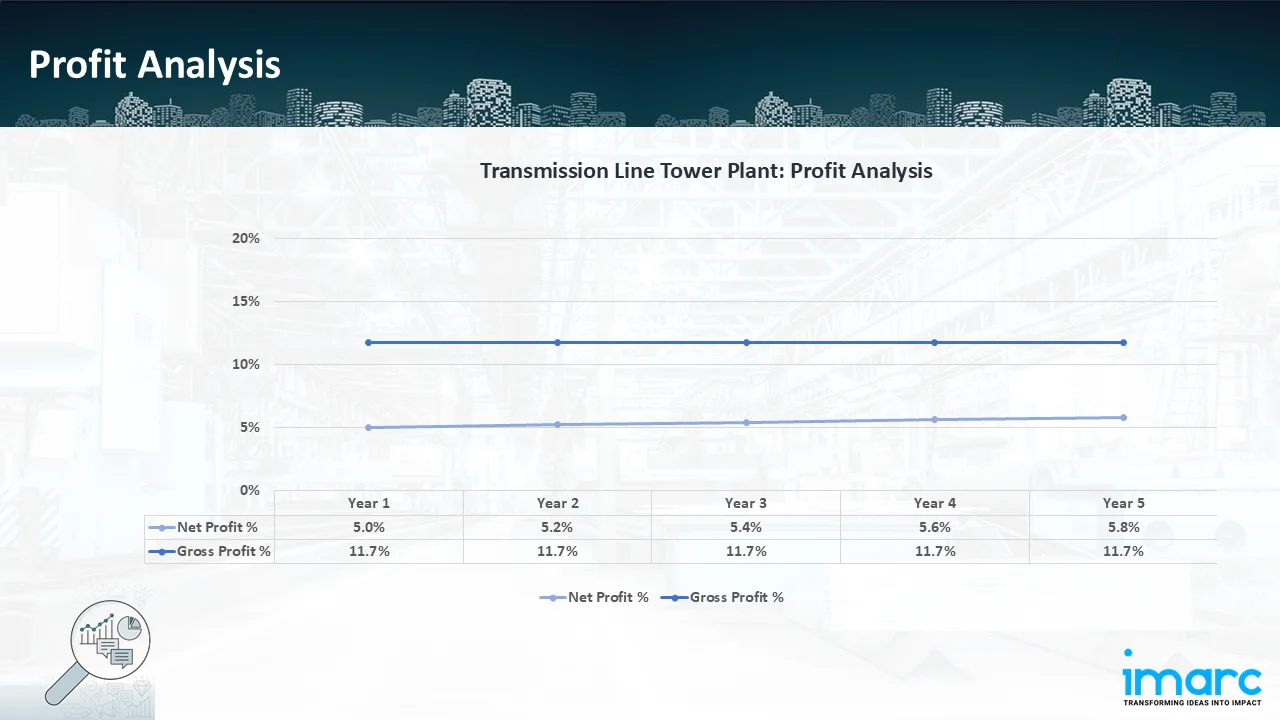

- Profitability Analysis Year on Year Basis: The proposed transmission line tower plant, with a capacity to produce 150,000 tons of rolling mill, and 60,000 tons of initial tower annually, achieved an impressive revenue of INR 3.83 Billion in its first year. We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins improve remains constant throughout the years at 11.7%, and net profit rises from 5.0% to 5.8%, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the transmission line tower manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of producing 150,000 tons of rolling mill, and 60,000 tons of initial tower annually, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In September 2025, Kshema Power has won a contract of Rs 1.08 billion to build a 400 kV transmission line in Andhra Pradesh. To carry electricity from a 1 GW wind farm, a 42-kilometer transmission line will be constructed in the Andhra Pradesh district of Ananthapuram. To guarantee dependable and effective power distribution, it will have a single-circuit line mounted atop double-circuit towers.

- In September 2025, KEC International, a significant worldwide infrastructure company and member of the RPG Group, announced recently that it has acquired new transmission and distribution (T&D) orders totalling INR 3,243 crore. The business stated in a BSE filing that the orders include the provision of towers, hardware, and poles in the Americas as well as 400 kilovolt (kV) transmission lines in the United Arab Emirates (UAE).

- In April 2025, the Northland Reliability Project, which will ensure continuous dependable electric supply in northern and central Minnesota as well as the larger Upper Midwest region, was unveiled today by Sabre Industries in collaboration with Great River Energy and Minnesota Power. Sabre will supply 180 miles of new 345-kV double-circuit transmission lines with highly engineered transmission structures as part of the collaboration deal. From Great River Energy's Benton County Substation near St. Cloud to Minnesota Power's Iron Range Substation in Itasca County and beyond to the Monticello, Minnesota area, this line is positioned strategically close to existing transmission arteries.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104