Cost Dynamics in Truck Radiator Manufacturing and Distribution: A Comprehensive Cost Model

_11zon.webp)

What is Truck Radiator?

A truck radiator is an essential part of the truck's cooling system, which is used to control engine temperature by dispersing the excess heat produced during running. The radiator functions by circulating a coolant liquid around the engine, absorbing heat, and then releasing the heat to the air through the radiator's finned surface.

Key Applications Across Industries:

Normally made of aluminum or copper-brass materials for the best heat conductivity and strength, truck radiators are designed to endure the harsh conditions of heavy-duty and long-haul transportation. Effective radiator operation is crucial for avoiding engine overheating, minimizing wear, saving fuel, and maintaining the reliability and longevity of commercial trucks. Contemporary radiators also feature sophisticated technologies like multi-flow channels and corrosion-resistant coatings to maximize thermal performance and life.

What the Expert Says: Market Overview & Growth Drivers

The global automotive radiator market reached USD 13.29 Billion in 2024. According to IMARC Group, the market is projected to reach USD 18.46 Billion by 2033, exhibiting a CAGR of 3.8% during 2025-2033. The truck radiator market is influenced by a combination of industrial, regulatory, and technological factors.

The demand for commercial transportation is increasing with growing e-commerce, logistics, and construction markets, and this demand has expanded heavy-duty truck production and operations, increasing the demand for reliable radiator systems. Stricter regulations concerning emission and fuel efficiency are forcing manufacturers to adopt more advanced cooling solutions, making high-performance radiators more critical. Moreover, increasing temperatures and extended mean haul distances in markets such as India, the U.S., and the Middle East boost the demand for efficient thermal management for trucks. The move towards lightweight materials and small, efficient designs to enhance vehicle efficiency also promotes radiator technology innovation. Moreover, the growing presence of electric and hybrid trucks, calling for distinct thermal control strategies, is opening new paths for radiator and thermal system development. Lastly, growth in aftermarket services, fleet maintenance contracts, and for high-durability radiators in harsh applications are also contributing to market growth.

Case Study on Cost Model of Truck Radiator Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a large-scale truck radiator manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed truck radiator manufacturing plant in Arizona, United States. This plant is designed to produce 320 pieces of truck radiator per day.

Manufacturing Process: Truck radiators are crucial to cool heavy-duty trucks and are produced in a comprehensive, multi-step procedure to ascertain ruggedness and efficiency. The procedure starts with a shearing machine cutting aluminum sheets to exact measurements, followed by a cutting machine cutting tubes to specified lengths. Fins are produced using a fins production machine, making thin metal sheets for optimal heat release. These fins and tubes are combined in a core on a core assembly machine, and the assembly is then brazed together in a furnace to form leak-tight, strong joints. After brazing, the radiator is leak tested by pressure or immersion to ensure dependability. Plastic tanks are afterwards clinched onto the radiator on a special machine, and then the airtightness is checked for detecting air leakage. The finishing processes are the drying of the unit to evaporate moisture and a surface repair phase for polishing or coating, which adds beauty and corrosion protection. This efficient process provides high-performance, rugged radiators appropriate for rugged truck applications.

_11zon.webp)

Mass Balance and Raw Material Required: The primary raw materials used in the refined truck radiator manufacturing plant include plastic tank, gasket, side plate, head plate, tube, fins, cladded aluminium foil and potassium flouro aluminate. For a plant manufacturing 1 piece of truck radiator, 2 unit of plastic tank, 2 unit of gasket, 2 unit of side plate, 2 unit of head plate, 142 unit of tube, 72 unit of fins, 0.053 kg/unit of cladded aluminium foil and 0.11 kg of potassium flouro aluminate is required.

Techno-Commercial Parameter:

- Capital Investment (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

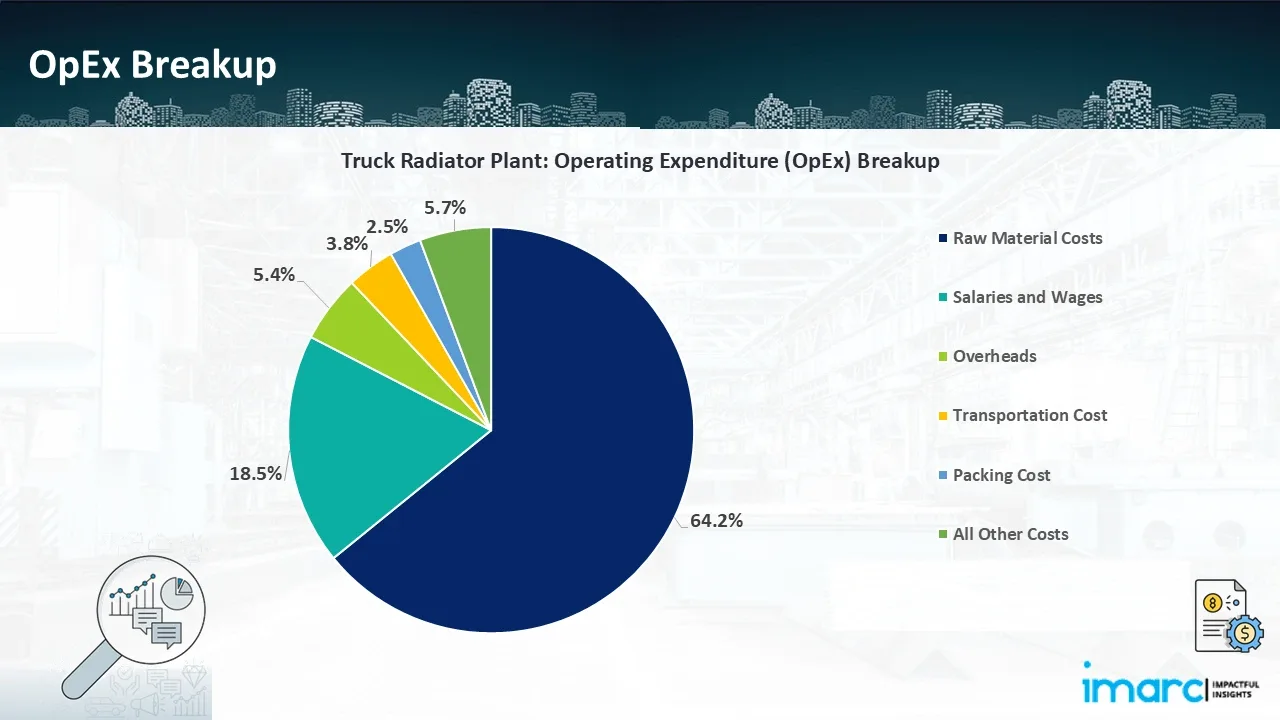

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. Opex in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth.

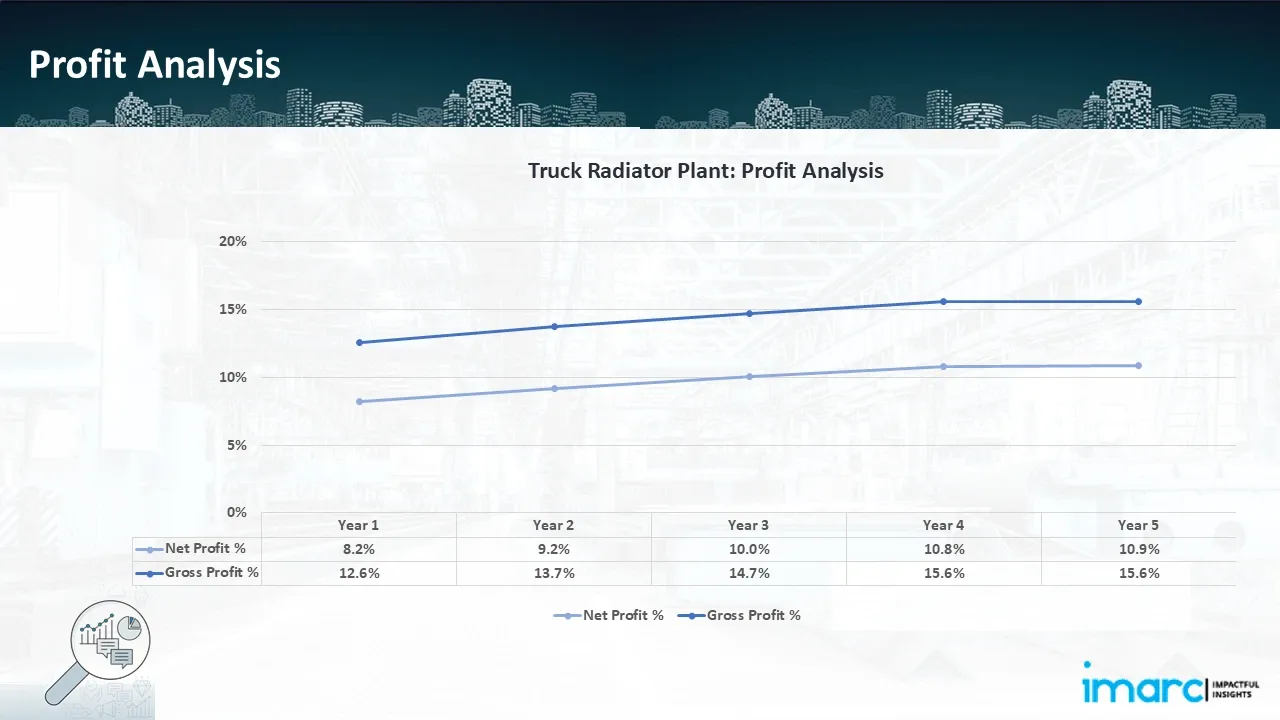

- Profitability Analysis Year on Year Basis: The proposed truck radiator plant, with a capacity of approximately 320 pieces of truck radiator per day, achieved an impressive revenue of US$ 8.35 million in its first year. We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins improve from 12.6% to 15.6% by year 5, and net profit rises from 8.2% to 10.9%, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the truck radiator manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of producing 320 pieces of truck radiators per day, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights for strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In July 2025, Active Radiator, a well-known heavy-duty cooling equipment manufacturer, distributor, and service provider in the United States, was acquired by LDR Partners LP. Now, Active will work with Ohio Heat Transfer and Cincinnati Radiator on a single platform: Active Thermal Solutions.

- In June 2025, the automotive ventures of Asia Investments Pvt Ltd (AIPL) will be acquired by Gabriel India, the flagship firm of the Anand Group. In addition to AIPL's assets in Dana Anand India, Henkel Anand India, and Anand CY Myutec Automotive, all of which will be merged into Gabriel India, this also includes Anchemco, a manufacturer of automotive fluids and adhesives. Automotive products such braking fluid, radiator coolants, diesel exhaust fluid (DEF)/AdBlue for 2W, 3W, 4W, and truck applications, as well as PU/PVC-based adhesives, are manufactured and sold by Anchemco.

- In September 2024, Northern Radiator (USA) constructed a new plant in Denver, Colorado, to improve aftermarket and fleet servicing efficiency and provide same-day or next-day service in the Mountain West region.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104