Aluminum Alloy Ingot Prices, Trend, Chart, Demand, Market Analysis, News, Historical and Forecast Data Report 2025 Edition

Aluminum Alloy Ingot Price Trend, Index and Forecast

Track the latest insights on aluminum alloy ingot price trend and forecast with detailed analysis of regional fluctuations and market dynamics across North America, Latin America, Central Europe, Western Europe, Eastern Europe, Middle East, North Africa, West Africa, Central and Southern Africa, Central Asia, Southeast Asia, South Asia, East Asia, and Oceania.

Aluminum Alloy Ingot Prices Outlook Q4 2025

- Japan: USD 2762/MT

- China: USD 3085/MT

- Germany: USD 2466/MT

- United Kingdom: USD 2560/MT

- USA: USD 2883/MT

Aluminum Alloy Ingot Price Chart

Get real-time access to monthly/quarterly/yearly prices Request Sample

During the fourth quarter of 2025, the aluminum alloy ingot prices in Japan reached 2762 USD/MT in December. Prices moved downward as demand from automotive manufacturing and consumer electronics moderated. Stable import flows and sufficient inventory availability supported supply conditions. Buyers adjusted procurement volumes to reflect measured downstream consumption.

During the fourth quarter of 2025, the aluminum alloy ingot prices in China reached 3085 USD/MT in December. Prices moved upward supported by firm demand from transportation equipment manufacturing and electrical applications. Production discipline among smelters and controlled supply availability tightened market conditions. Buyers increased procurement to meet steady industrial requirements and fabrication activity.

During the fourth quarter of 2025, the aluminum alloy ingot prices in Germany reached 2466 USD/MT in December. Prices declined as demand from automotive components and industrial manufacturing softened. Adequate regional supply and stable recycling inflows reduced sourcing pressure. Buyers aligned procurement closely with production schedules and inventory management priorities.

During the fourth quarter of 2025, the aluminum alloy ingot prices in the United Kingdom reached 2560 USD/MT in December. Prices moved upward driven by steady demand from construction and transportation segments. Import reliance and logistical considerations influenced supply availability. Buyers focused on securing consistent volumes amid limited short-term sourcing flexibility.

During the fourth quarter of 2025, the aluminum alloy ingot prices in the USA reached 2883 USD/MT in December. Prices moved downward as demand from the automotive and construction sectors moderated. Buyers adopted cautious procurement strategies amid sufficient domestic availability and steady secondary aluminum supply. Softer downstream manufacturing schedules influenced purchasing patterns across spot and contract markets.

Aluminum Alloy Ingot Prices Outlook Q3 2025

- Japan: USD 2830/MT

- China: USD 2975/MT

- Germany: USD 2532/MT

- United Kingdom: USD 2477/MT

- USA: USD 2918/MT

During the third quarter of 2025, the aluminum alloy ingot prices in Japan reached 2830 USD/MT in September. Market sentiment improved as automotive manufacturers increased melt-shop output, stimulating greater alloy demand. Smelters managed rising operational costs linked to energy and alloying inputs. Import flows shifted due to evolving supply availability in neighboring markets, prompting domestic buyers to advance purchases earlier in the quarter.

During the third quarter of 2025, the aluminum alloy ingot prices in China reached 2975 USD/MT in September. Prices rose as downstream casting, transportation, and machinery industries expanded their procurement needs. Smelters navigated fluctuating power allocation policies in industrial provinces, which influenced output steadiness. Export-oriented enterprises intensified intake amid stronger foreign demand, while transport adjustments affected regional distribution patterns.

During the third quarter of 2025, the aluminum alloy ingot prices in Germany reached 2532 USD/MT in September. Pricing increased as die-casting and engineered component manufacturers registered stronger order flow. Elevated energy expenses continued to affect smelting operations. Cross-border transport inefficiencies contributed to localized shortages, encouraging procurement ahead of planned production rounds.

During the third quarter of 2025, the aluminum alloy ingot prices in the United Kingdom reached 2477 USD/MT in September. Prices moved upward following a recovery in casting activity within automotive and machinery segments. Importers encountered longer maritime transit times due to vessel scheduling adjustments. Currency-related cost impacts influenced distributor stocking strategies across the country.

During the third quarter of 2025, the aluminum alloy ingot prices in the USA reached 2918 USD/MT in September. A notable price rise reflected expanding demand from transportation and construction industries. Smelters faced rising alloying material costs and operational adjustments tied to workforce constraints. Domestic transportation networks experienced capacity tightness, prompting earlier ordering behavior across major manufacturing regions.

Aluminum Alloy Ingot Prices Outlook Q2 2025

- Mexico: USD 2976/MT

- China: USD 2850/MT

- Germany: USD 2492/MT

- United Kingdom: USD 2445/MT

- USA: USD 2615/MT

During the second quarter of 2025, the aluminum alloy ingot prices in Mexico reached 2976 USD/MT in June. In Mexico, aluminum alloy ingot prices were influenced by fluctuations in primary aluminum imports, which faced delays due to port congestion and stricter customs inspections. Demand from the automotive manufacturing sector remained consistent, though some Tier-2 suppliers adjusted orders due to excess inventory. Additionally, energy costs for local smelters, particularly in northern regions, saw moderate increases, contributing to elevated production expenses.

During the second quarter of 2025, aluminum alloy ingot prices in China reached 2850 USD/MT in June. In China, production curbs in certain provinces driven by energy intensity reduction targets impacted the availability of aluminum alloy ingots. Downstream demand from the construction and electronics manufacturing sectors remained steady, while a marginal increase in secondary aluminum recycling activity helped offset primary aluminum supply constraints. Export volumes were also affected by logistics bottlenecks and container shortages at major ports.

During the second quarter of 2025, the aluminum alloy ingot prices in Germany reached 2492 USD/MT in June. Germany’s Q2 2025 aluminum alloy ingot prices were primarily influenced by high industrial electricity prices and extended maintenance shutdowns at several foundries. Automotive and aerospace sectors’ demand exhibited partial recovery, placing upward pressure on procurement schedules. The availability of scrap aluminum declined due to lower collection volumes, while imports faced costlier logistics and longer lead times from Eastern European suppliers.

During the second quarter of 2025, the aluminum alloy ingot prices in the United Kingdom reached 2445 USD/MT in June. The UK’s prices were affected by volatility in imported billet costs and the limited availability of recycled aluminum feedstock. The automotive sector’s cautious restocking approach created inconsistent demand, while industrial energy tariffs and carbon compliance obligations raised operating costs. Currency fluctuations also influenced the landed cost of imported aluminum alloy ingots from European and Asian markets.

During the second quarter of 2025, the aluminum alloy ingot prices in the USA reached 2615 USD/MT in June. In the United States, price movements for aluminum alloy ingots were shaped by firm demand from the automotive and construction sectors and fluctuating premiums on imported primary aluminum. Domestic secondary smelters faced operational challenges due to labor constraints and rising natural gas prices. Trade flows from Canada remained steady, although shipments from Asia faced longer transit times and higher freight costs.

Aluminum Alloy Ingot Prices Outlook Q1 2025

- USA: USD 2880/ MT

- Mexico: USD 3087/MT

- Japan: USD 2767/ MT

- Germany: USD 2561/MT

- Indonesia: USD 2875/MT

During the first quarter of 2025, the aluminum alloy ingot prices in the USA reached 2880 USD/MT in March. The market maintained a rising price trend, bolstered by supply constraints and robust domestic demand, especially from the construction and automotive sectors. Besides, an upward pressure was added by export interest and the decline in LME stocks.

During the first quarter of 2025, the aluminum alloy ingot prices in Mexico reached 3087 USD/MT in March. The market showed consistent growth, bolstered by enhanced demand from automotive manufacturing and construction activities. Although the country profited from trade integration and closeness to American markets, the costs of imported materials increased due to new tariffs. Moreover, there was added pressure due to local supply constraints and high transport costs.

During the first quarter of 2025, the aluminum alloy ingot prices in Japan reached 2767 USD/MT in March. As per the aluminum alloy ingot price chart, Japan saw a moderate increase, fueled by a revival in car manufacturing and activity in the technology sector. Trade imbalances and the fragility of supply chains affected sourcing costs, while a heightened reliance on imports contributed to volatility. The expansion of manufacturing was consistent but measured, contributing to the firmness of the market.

During the first quarter of 2025, the aluminum alloy ingot prices in Germany reached 2561 USD/MT in March. Consistent support came from the reduced availability of scrap and the increasing consumption related to electric vehicles. Nevertheless, economic challenges, especially supply interruptions and low industrial production, impeded wider recovery efforts. Market sentiment continued to be cautious, exacerbated by freight bottlenecks and geopolitical unease.

During the first quarter of 2025, the aluminum alloy ingot prices in Indonesia reached 2875 USD/MT in March. Prices in Indonesia increased as a result of robust demand from the automotive and electronics industries. Besides, an initiative by the government aimed at improving domestic processing of alumina also contributed to the stability of production. Although cost inflation and currency fluctuations caused volatility, the surge in infrastructure activity and the industry’s strength helped stabilize prices.

.webp)

Regional Coverage

The report provides a detailed analysis of the market across different regions, each with unique pricing dynamics influenced by localized market conditions, supply chain intricacies, and geopolitical factors. This includes price trends, price forecast and supply and demand trends for each region, along with spot prices by major ports. The report also provides coverage of FOB and CIF prices, as well as the key factors influencing the aluminum alloy ingot prices.

Europe Aluminum Alloy Ingot Price Trend

Q4 2025:

As per the aluminum alloy ingot price index, Europe experienced mixed pricing conditions during this quarter, reflecting declines in Germany and increases in the United Kingdom. Demand from the automotive and industrial manufacturing sectors remained uneven across the region. Buyers in continental Europe emphasized inventory control amid steady secondary aluminum availability, while UK buyers faced tighter import-driven supply conditions. Procurement strategies varied by market, shaped by localized manufacturing activity and sourcing dependencies.

Q3 2025:

Europe experienced rising prices in line with upward movements in Germany and the United Kingdom. Automotive casting operations expanded in Central and Western Europe, increasing procurement from melt shops. Energy cost pressures persisted across smelters, affecting production economics. Congestion in several Northern European ports lengthened inbound transit times for imported alloying inputs. Inland transport limitations across Germany and the Benelux influenced distributors’ ability to meet scheduled deliveries for component manufacturers.

Q2 2025:

In Europe, aluminum alloy ingot prices were influenced by elevated energy input costs, especially electricity rates affecting foundries in Germany and France. The demand from the automotive and packaging sectors remained stable, while production disruptions occurred due to ongoing labor shortages and raw material sourcing delays. Import reliance increased amid reduced domestic secondary aluminum output, contributing to variability in supply chain costs across the region.

Q1 2025:

As per the aluminum alloy ingot price index, the market faced price increases as a result of limited availability and steady industrial demand. The market sentiment was influenced by seasonal scrap shortages, dwindling LME reserves, and impending regulations targeting Russian imports. Nonetheless, the recovery was still hindered by a lack of strength in domestic manufacturing, logistical disruptions, such as the incident involving the Moselle River, and geopolitical uncertainty. Besides, the optimism regarding prices was upheld by the robustness of demand and the low levels of inventory.

This analysis can be extended to include detailed aluminum alloy ingot price information for a comprehensive list of countries.

| Region | Countries Covered |

|---|---|

| Europe | Germany, France, United Kingdom, Italy, Spain, Russia, Turkey, Netherlands, Poland, Sweden, Belgium, Austria, Ireland, Switzerland, Norway, Denmark, Romania, Finland, Czech Republic, Portugal, and Greece, among other European countries. |

North America Aluminum Alloy Ingot Price Trend

Q4 2025:

As per the aluminum alloy ingot price index, North America recorded a downward pricing trend, influenced by the decline observed in the USA. Softer demand from automotive manufacturing and construction activity reduced consumption intensity. Domestic production and recycled material availability ensured adequate supply. Buyers prioritized contract-based sourcing and short-term procurement aligned with confirmed production requirements.

Q3 2025:

North America recorded higher pricing consistent with increases in the USA. Automotive, machinery, and construction sectors expanded ordering activity, encouraging stronger melt-shop utilization. Smelters contended with rising alloying input costs and operational constraints linked to workforce conditions. Trucking networks across key corridors operated under capacity pressure, extending lead times. Manufacturers in multiple states diversified sourcing channels to maintain supply continuity under shifting transportation dynamics.

Q2 2025:

In North America, pricing dynamics were shaped by consistent demand from the construction and transportation equipment manufacturing sectors. Domestic production faced cost pressures from higher natural gas prices and maintenance downtime at multiple recycling facilities. Trade volumes with Canada remained relatively unaffected, although shipments from Asia experienced delays due to congested West Coast ports and tightened container availability, raising logistical expenses.

Q1 2025:

The market showed moderate price increases, driven by ongoing demand from the end-use sector and changes in import regulations. Although domestic production remained stable, dependence on materials sourced from abroad was still significant. Moreover, the market’s upward momentum was bolstered by diminishing stockpiles, vigorous activity in the electric vehicle (EV) sector and construction sectors, and a tightening of scrap availability.

Specific aluminum alloy ingot historical data within the United States and Canada can also be provided.

| Region | Countries Covered |

|---|---|

| North America | United States and Canada |

Middle East and Africa Aluminum Alloy Ingot Price Trend

Q4 2025:

As per aluminum alloy ingot price chart, the prices in the Middle East and Africa fluctuated due to a complex interplay of factors, primarily driven by supply chain disruptions, seasonal demand shifts, and geopolitical influences.

Q3 2025:

The report explores the aluminum alloy ingot pricing trends and aluminum alloy ingot price chart in the Middle East and Africa, considering factors like regional industrial growth, the availability of natural resources, and geopolitical tensions that uniquely influence market prices.

In addition to region-wise data, information on aluminum alloy ingot prices for countries can also be provided.

| Region | Countries Covered |

|---|---|

| Middle East & Africa | Saudi Arabia, UAE, Israel, Iran, South Africa, Nigeria, Oman, Kuwait, Qatar, Iraq, Egypt, Algeria, and Morocco, among other Middle Eastern and African countries. |

Asia Pacific Aluminum Alloy Ingot Price Trend

Q4 2025:

Asia Pacific experienced mixed pricing dynamics, driven by the increase observed in China and the decline noted in Japan. Strong industrial activity in China supported demand from transportation and electrical applications, while moderated consumption in Japan influenced regional balance. Buyers adjusted procurement strategies based on localized manufacturing trends, supply availability, and import dependencies across key markets.

Q3 2025:

Asia Pacific pricing increased in line with rising prices in Japan and China. Automotive, electronics, and machinery industries supported firmer procurement across major production hubs. Japanese melt shops elevated booking levels, while Chinese smelters adjusted operational patterns in response to evolving industrial activity and regional energy considerations. Southeast Asian importers adapted to fluctuating freight schedules as carriers modified Asia–Europe rotations. South Asian manufacturers navigated inland transport constraints that affected timely material movement to casting operations.

Q2 2025:

In the Asia Pacific region, fluctuations in aluminum alloy ingot prices were driven by varying regional energy policies and production restrictions, particularly in China and India. The automotive and consumer electronics sectors sustained demand, while secondary aluminum output was impacted by limited scrap collection. Export-oriented smelters in Southeast Asia encountered longer shipping lead times and rising freight charges, influencing contract negotiations.

Q1 2025:

The market saw a positive pricing trend, driven by increased industrial activity and changing global trade dynamics. Regional production was disrupted due to limited Chinese exports and temporary shutdowns, particularly affecting Southeast Asia. Indonesia experienced consistent price hikes, fueled by rising demand in the automotive and electronics sectors and logistical delays during the mid-quarter. Besides, improved alumina availability and infrastructure enhancements provided stability. Despite complexities arising from fluctuations in input costs and currency, Indonesia’s strategic emphasis on enhancing domestic aluminum production bolstered market resilience amid strong underlying demand.

This aluminum alloy ingot price analysis can be expanded to include a comprehensive list of countries within the region.

| Region | Countries Covered |

|---|---|

| Asia Pacific | China, India, Indonesia, Pakistan, Bangladesh, Japan, Philippines, Vietnam, Thailand, South Korea, Malaysia, Nepal, Taiwan, Sri Lanka, Hongkong, Singapore, Australia, and New Zealand, among other Asian countries. |

Latin America Aluminum Alloy Ingot Price Trend

Q4 2025:

Latin America's aluminum alloy ingot market is predominantly influenced by its rich natural reserves, particularly in countries like Chile and Brazil. However, political instability and inconsistent regulatory frameworks can lead to significant volatility in aluminum alloy ingot prices.

Q3 2025:

Infrastructure challenges and logistical inefficiencies often impact the supply chain, affecting Latin America’s ability to meet international demand consistently. Moreover, the aluminum alloy ingot price index, economic fluctuations, and currency devaluation are critical factors that need to be considered when analyzing aluminum alloy ingot pricing trends in this region.

This comprehensive review can be extended to include specific countries within the region.

| Region | Countries Covered |

|---|---|

| Latin America | Brazil, Mexico, Argentina, Columbia, Chile, Ecuador, and Peru, among other Latin American countries. |

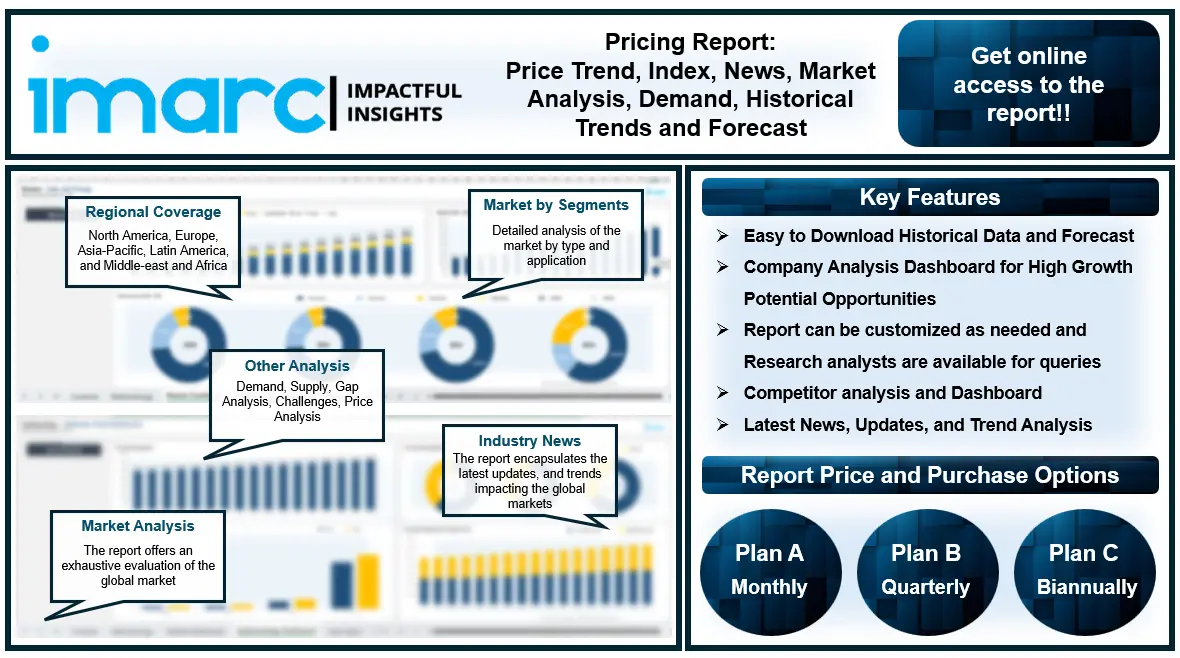

Aluminum Alloy Ingot Pricing Report, Market Analysis, and News

IMARC's latest publication, “Aluminum Alloy Ingot Prices, Trend, Chart, Demand, Market Analysis, News, Historical and Forecast Data Report 2025 Edition,” presents a detailed examination of the aluminum alloy ingot market, providing insights into both global and regional trends that are shaping prices. This report delves into the spot price of aluminum alloy ingot at major ports and analyzes the composition of prices, including FOB and CIF terms. It also presents detailed aluminum alloy ingot prices trend analysis by region, covering North America, Europe, Asia Pacific, Latin America, and Middle East and Africa. The factors affecting aluminum alloy ingot pricing, such as the dynamics of supply and demand, geopolitical influences, and sector-specific developments, are thoroughly explored. This comprehensive report helps stakeholders stay informed with the latest market news, regulatory updates, and technological progress, facilitating informed strategic decision-making and forecasting.

Aluminum Alloy Ingot Industry Analysis

The global aluminum alloy ingot industry size reached 116.5 Thousand Tons in 2025. By 2034, IMARC Group expects the market to reach 148.2 Thousand Tons, at a projected CAGR of 2.71% during 2026-2034. Growth is driven by expanding use of aluminum castings in transportation, industrial machinery, and construction, supported by ongoing light-weighting initiatives. Increasing alloy demand from electronics and renewable energy applications also contributes to long-term industry expansion.

Latest News and Developments:

- September 2025: Norsk Hydro expanded its Hydro CIRCAL recycled aluminum line to include foundry alloy ingots alongside extrusion ingots with at least 75% post-consumer scrap, supporting automotive makers in reducing emissions and improving material circularity. The addition of aluminum alloy ingot options strengthens decarbonization efforts for wheels, battery boxes, structural parts, and engine components.

- July 2025: India’s Vedanta Aluminum confirmed a major expansion of its Special Economic Zone (SEZ) unit in Jharsuguda, by increasing the installed capacity of its Primary Foundry Alloy (PFA) unit by 120 KTPA (kilo tons per annum). The expansion was described as a strategic move to enhance value-added aluminum offerings and position India as a global hub for advanced aluminum solutions.

Product Description

Aluminum alloy ingot is a type of material which is created by combining aluminum with various other metals to improve its properties. The addition of various elements like copper, magnesium, silicon and zinc helps in enhancing its strength, resistance to corrosion and durability. The manufacturing process of aluminum alloy ingots involves melting the base aluminum and then adding the alloying elements in precise proportions. The molten alloy is then transferred into molds to solidify. Once cooled and solidified the aluminum ingots can be further processed through rolling, extrusion, or forging to produce components and structures used in various industries which includes automotive, aerospace, construction, and electronics. Aluminum alloy ingots are valuable resources in sustainable manufacturing and construction practices due to their versatility and recyclability. This has contributed to their growing demand in the global market.

Report Coverage

| Key Attributes | Details |

|---|---|

| Product Name | Aluminum Alloy Ingot |

| Report Features | Exploration of Historical Trends and Market Outlook, Industry Demand, Industry Supply, Gap Analysis, Challenges, Aluminum Alloy Ingot Price Analysis, and Segment-Wise Assessment. |

| Currency/Units | US$ (Data can also be provided in local currency) or Metric Tons |

| Region/Countries Covered | The current coverage includes analysis at the global and regional levels only. Based on your requirements, we can also customize the report and provide specific information for the following countries: Asia Pacific: China, India, Indonesia, Pakistan, Bangladesh, Japan, Philippines, Vietnam, Thailand, South Korea, Malaysia, Nepal, Taiwan, Sri Lanka, Hongkong, Singapore, Australia, and New Zealand* Europe: Germany, France, United Kingdom, Italy, Spain, Russia, Turkey, Netherlands, Poland, Sweden, Belgium, Austria, Ireland, Switzerland, Norway, Denmark, Romania, Finland, Czech Republic, Portugal and Greece* North America: United States and Canada Latin America: Brazil, Mexico, Argentina, Columbia, Chile, Ecuador, and Peru* Middle East & Africa: Saudi Arabia, UAE, Israel, Iran, South Africa, Nigeria, Oman, Kuwait, Qatar, Iraq, Egypt, Algeria, and Morocco* *The list of countries presented is not exhaustive. Information on additional countries can be provided if required by the client. |

| Information Covered for Key Suppliers |

|

| Customization Scope | The report can be customized as per the requirements of the customer |

| Report Price and Purchase Option |

Plan A: Monthly Updates - Annual Subscription

Includes: One PDF and Excel datasheet per month, Post Purchase Analyst Support throughout the year Plan B: Quarterly Updates - Annual Subscription

Includes: One PDF and Excel datasheet per Quarter, Post Purchase Analyst Support throughout the year Plan C: Biannually Updates - Annual Subscription

Includes: One PDF and Excel datasheet per Half, Post Purchase Analyst Support throughout the year |

| Post-Sale Analyst Support | 360-degree analyst support after report delivery |

| Delivery Format | PDF and Excel through email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Benefits for Stakeholders:

- IMARC’s report presents a detailed analysis of aluminum alloy ingot pricing, covering global and regional trends, spot prices at key ports, and a breakdown of FOB and CIF prices.

- The study examines factors affecting aluminum alloy ingot price trend, including input costs, supply-demand shifts, and geopolitical impacts, offering insights for informed decision-making.

- The competitive landscape review equips stakeholders with crucial insights into the latest market news, regulatory changes, and technological advancements, ensuring a well-rounded, strategic overview for forecasting and planning.

- IMARC offers various subscription options, including monthly, quarterly, and biannual updates, allowing clients to stay informed with the latest market trends, ongoing developments, and comprehensive market insights. The aluminum alloy ingot price charts ensure our clients remain at the forefront of the industry.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Why Choose Us

IMARC offers trustworthy, data-centric insights into commodity pricing and evolving market trends, enabling businesses to make well-informed decisions in areas such as procurement, strategic planning, and investments. With in-depth knowledge spanning more than 1000 commodities and a vast global presence in over 150 countries, we provide tailored, actionable intelligence designed to meet the specific needs of diverse industries and markets.

1000

+Commodities

150

+Countries Covered

3000

+Clients

20

+Industry

Robust Methodologies & Extensive Resources

IMARC delivers precise commodity pricing insights using proven methodologies and a wealth of data to support strategic decision-making.

Subscription-Based Databases

Our extensive databases provide detailed commodity pricing, import-export trade statistics, and shipment-level tracking for comprehensive market analysis.

Primary Research-Driven Insights

Through direct supplier surveys and expert interviews, we gather real-time market data to enhance pricing accuracy and trend forecasting.

Extensive Secondary Research

We analyze industry reports, trade publications, and market studies to offer tailored intelligence and actionable commodity market insights.

Trusted by 3000+ industry leaders worldwide to drive data-backed decisions. From global manufacturers to government agencies, our clients rely on us for accurate pricing, deep market intelligence, and forward-looking insights.

Request Customization

Request Customization

Inquire Before Buying

Inquire Before Buying

Speak to an Analyst

Speak to an Analyst Request Brochure

Request Brochure

.webp)

.webp)