Australia Hydraulic Press Market Size, Share, Trends and Forecast by Type, Application, End-User, and Region, 2025-2033

Australia Hydraulic Press Market Overview:

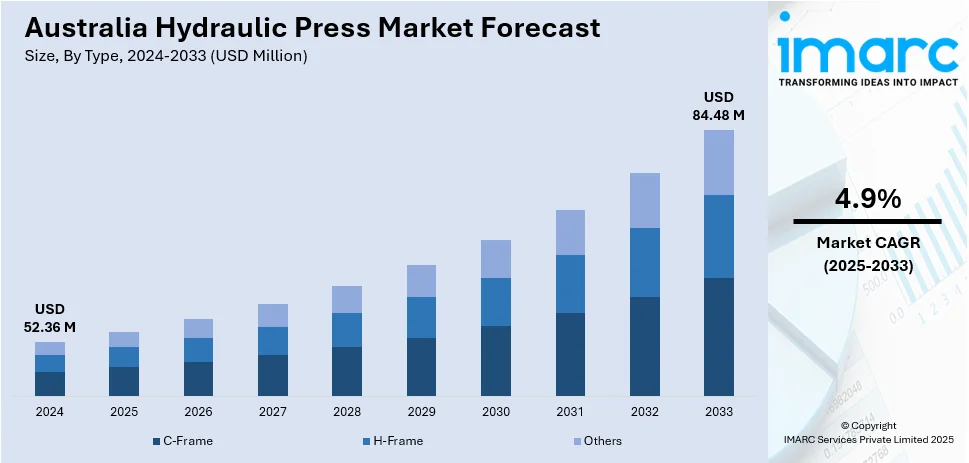

The Australia hydraulic press market size reached USD 52.36 Million in 2024. Looking forward, the market is projected to reach USD 84.48 Million by 2033, exhibiting a growth rate (CAGR) of 4.9% during 2025-2033. Rising demand in metal fabrication, automotive servicing, and recycling industries is one of the factors contributing to Australia hydraulic press market share. Growth in mining operations and infrastructure projects also fuels adoption. Advancements in automation and energy-efficient systems further support market expansion across industrial and manufacturing applications.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2024

|

|

Forecast Years

|

2025-2033

|

|

Historical Years

|

2019-2024

|

| Market Size in 2024 | USD 52.36 Million |

| Market Forecast in 2033 | USD 84.48 Million |

| Market Growth Rate 2025-2033 | 4.9% |

Key Trends of Australia Hydraulic Press Market:

Modernization of Legacy Hydraulic Systems

There is a growing focus on upgrading aging hydraulic press systems across Australia to align with current safety and performance benchmarks. Industrial operators are increasingly investing in complete overhauls, including advanced PLC integration, updated HMIs, and compliance with higher safety categories. This shift is driven by the need to extend equipment life, reduce downtime, and meet strict regulatory requirements. Modernization efforts are particularly concentrated in heavy-duty presses used in sectors like mining, automotive, and metal fabrication. Upgraded systems offer better reliability, improved diagnostics, and easier maintenance. The adoption of newer control architectures and rewired operational panels reflects a broader industry movement toward efficiency and safety, with many facilities transitioning from legacy systems to digitally enabled, precision-controlled press operations. These factors are intensifying the Australia hydraulic press market growth. For instance, in March 2025, METSO Australia’s 1800-tonne hydraulic press was successfully refurbished by Scadalectric Automation, enhancing its performance, safety, and reliability. Key upgrades included a new Siemens S7-1200 PLC, reprogrammed HMI integration, Category 4 safety circuit enhancements, and full control panel rewiring. This project highlights the growing focus on modernizing heavy industrial equipment in Australia’s hydraulic press market to meet evolving operational and safety standards.

To get more information on this market, Request Sample

Focus on Control System Upgrades in Hydraulic Press Operations

Across Australia, manufacturers are increasingly prioritizing the enhancement of hydraulic press control systems. This shift stems from a practical need to improve machine responsiveness, operator safety, and integration with broader factory automation systems. Older presses, though structurally sound, often operate on outdated controllers that lack the precision, monitoring capabilities, and safety functions of current technologies. As a result, many operators are opting to retrofit these machines with programmable logic controllers (PLCs), updated human-machine interfaces (HMIs), and advanced safety systems. These upgrades not only minimize operational risk but also enable better data tracking, quicker fault detection, and remote diagnostics, which are essential in maintaining uptime in high-volume environments. The focus is not just on hardware; software reprogramming and system reconfiguration are central to ensuring compatibility and optimized functionality. In sectors such as mining, metal processing, and heavy equipment manufacturing, where hydraulic presses are critical assets, these improvements help maximize productivity while extending machine lifespan. The movement toward smarter, safer, and more responsive hydraulic press setups is becoming a priority for facilities seeking long-term operational resilience and regulatory compliance without investing in entirely new machinery.

Customization and Versatility

One major trend affecting the hydraulic press market in Australia is the growing need for customized and versatile machines. The end-users across the automotive, mining, construction, and manufacturing sectors are seeking presses that have the ability to be adjusted for individual processes for example stamping, molding, forging, or assembly. This shift indicates the requirement for better operating flexibility and productivity where one machine should be able to do multiple operations without compromising on performance. Subsequently, producers are designing modular hydraulic presses that are easily upgradable with interchangeable parts and sophisticated control systems. This flexibility is considerably driving Australia hydraulic press market demand as businesses focus on equipment that minimizes downtime, boosts productivity, and meets various industrial needs in a competitive landscape.

Growth Drivers of Australia Hydraulic Press Market:

Expanding Automotive Production

The automotive industry in Australia has a profound impact on the hydraulic press industry because of the growing demand for effective component forming and assembly solutions. Hydraulic presses are regularly used when manufacturing body parts for automobiles, engine parts, and repair jobs because they are precise and strong. With automobile manufacturers and aftermarket service providers seeking ways to improve production speed and dependability, reliance on state-of-the-art hydraulic systems is heightened. In addition, the shift toward lighter materials and new designs is creating further opportunities for specialized presses. This continued expansion in automotive production is causing hydraulic presses to be adopted further, establishing the sector as a premier end-user and fueling the overall growth of the market.

Industrial Modernization

The modernization of manufacturing processes across Australia is significantly increasing the demand for hydraulic presses. With industries shifting toward automation and intelligent machinery, presses featuring advanced controls, sensors, and monitoring systems are becoming more appealing. These advancements enable manufacturers to achieve greater accuracy, consistency, and efficiency in production. According to Australia hydraulic press market analysis, companies are progressively investing in upgraded hydraulic systems to enhance their competitiveness and meet global quality standards. This demand spans various sectors including aerospace and defense, consumer goods, and heavy machinery. By incorporating precision-driven presses businesses can minimize waste, optimize costs, and address the evolving expectations of both domestic and international markets.

Infrastructure and Mining Growth

Australia’s vibrant infrastructure development and mining operations are significant drivers of increasing demand for hydraulic presses. In the mining sector these machines are vital for material shaping, equipment fabrication, and maintenance tasks while in construction they are crucial for producing structural components. The rise of large-scale projects such as transportation networks, renewable energy infrastructure, and urban development is creating consistent needs for heavy-duty presses with substantial capacity. Moreover, mining companies are investing in advanced equipment to enhance efficiency in resource extraction and processing. These elements are propelling the strong adoption of hydraulic presses within heavy industries further establishing their importance as essential tools in Australia’s evolving industrial landscape.

Australia Hydraulic Press Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the country and regional levels for 2025-2033. Our report has categorized the market based on type, application, and end-user.

Type Insights:

- C-Frame

- H-Frame

- Others

The report has provided a detailed breakup and analysis of the market based on the type. This includes C-frame, H-frame, and others.

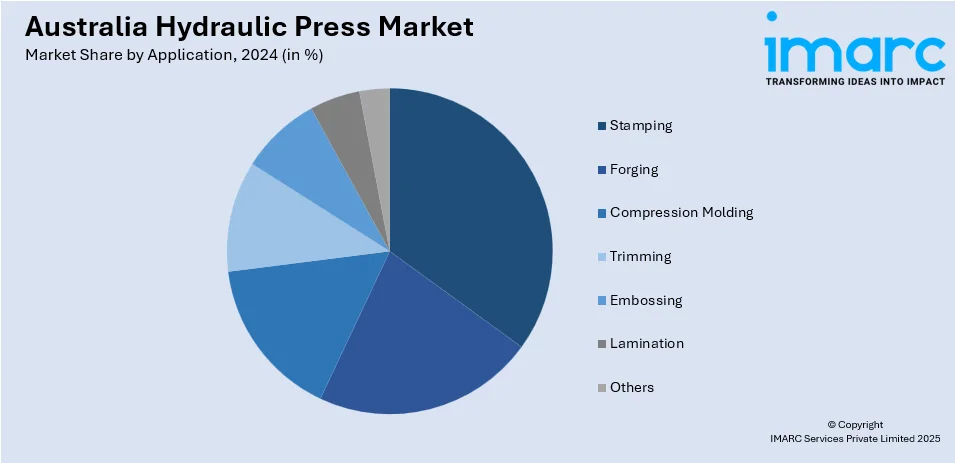

Application Insights:

- Stamping

- Forging

- Compression Molding

- Trimming

- Embossing

- Lamination

- Others

A detailed breakup and analysis of the market based on the application have also been provided in the report. This includes stamping, forging, compression molding, trimming, embossing, lamination, and others.

End-User Insights:

- Automotive

- Food and Beverage

- Metal Fabrication

- Manufacturing

- Others

A detailed breakup and analysis of the market based on the end-user have also been provided in the report. This includes automotive, food and beverage, metal fabrication, manufacturing, and others.

Regional Insights:

- Australia Capital Territory and New South Wales

- Victoria and Tasmania

- Queensland

- Northern Territory and Southern Australia

- Western Australia

The report has also provided a comprehensive analysis of all the major regional markets, which include Australia Capital Territory and New South Wales, Victoria and Tasmania, Queensland, Northern Territory and Southern Australia, and Western Australia.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

Australia Hydraulic Press Market News:

- In May 2025, at the 2025 Brisbane Truck Show, Hydreco Australia introduced advanced hydraulic solutions designed for transport and mobile machinery. Key products included the Endurant and Euro PTOs, plus a compact closed-coupled water pump for tight-space installations. The showcase strengthened Hydreco’s presence in Australia’s hydraulic press market, drawing strong interest from OEMs and distributors and reinforcing demand for innovative, high-performance hydraulic systems in industrial applications.

Australia Hydraulic Press Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2024 |

| Historical Period | 2019-2024 |

| Forecast Period | 2025-2033 |

| Units | Million USD |

| Scope of the Report |

Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Types Covered | C-Frame, H-Frame, Others |

| Applications Covered | Stamping, Forging, Compression Molding, Trimming, Embossing, Lamination, Others |

| End-Users Covered | Automotive, Food and Beverage, Metal Fabrication, Manufacturing, Others |

| Regions Covered | Australia Capital Territory and New South Wales, Victoria and Tasmania, Queensland, Northern Territory and Southern Australia, Western Australia |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the Australia hydraulic press market from 2019-2033.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the Australia hydraulic press market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the Australia hydraulic press industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Key Questions Answered in This Report

The hydraulic press market in Australia was valued at USD 52.36 Million in 2024.

The Australia hydraulic press market is projected to exhibit a compound annual growth rate (CAGR) of 4.9% during 2025-2033.

The Australia hydraulic press market is expected to reach a value of USD 84.48 Billion by 2033.

The Australia hydraulic press market is witnessing growing adoption of automation and smart controls, energy-efficient systems, and multifunctional designs. Customizable presses and integration with digital monitoring solutions are further driving operational flexibility and improved precision across sectors.

Rising industrial modernization, expanding automotive production, and infrastructure and mining growth are key drivers. Businesses are investing in high-efficiency, durable, and heavy-duty presses. Increasing need for customized equipment and performance optimization is fueling market expansion, while emphasis on productivity, precision, and reduced downtime further supports demand growth across industries.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)