Australia Industrial Mixers and Agitators Market Size, Share, Trends and Forecast by Type, Application, and Region, 2025-2033

Australia Industrial Mixers and Agitators Market Overview:

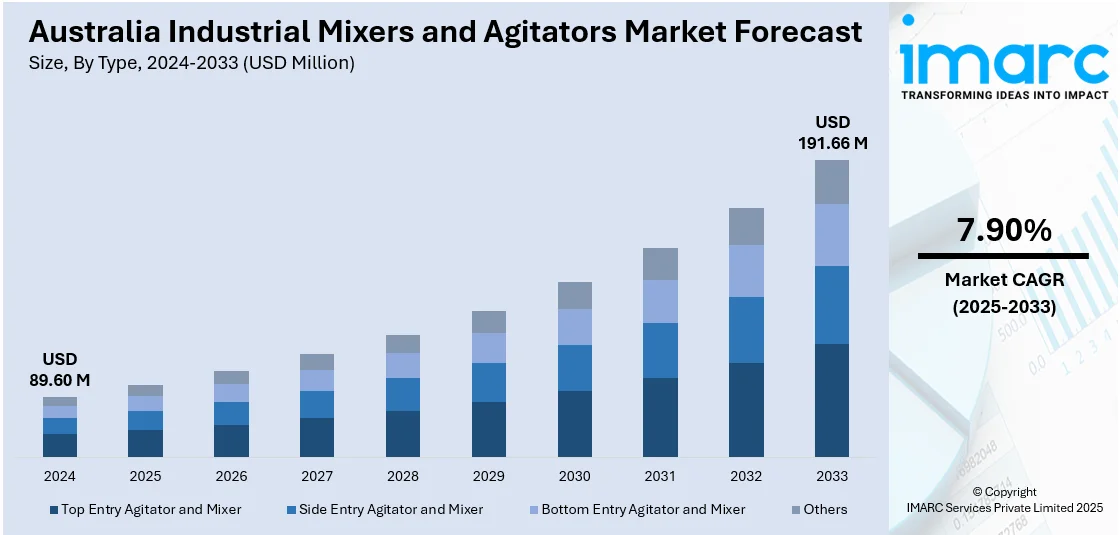

The Australia industrial mixers and agitators market size reached USD 89.60 Million in 2024. Looking forward, IMARC Group expects the market to reach USD 191.66 Million by 2033, exhibiting a growth rate (CAGR) of 7.90% during 2025-2033. The market is fueled by growing demand in industries such as food, pharmaceuticals, and chemicals. Expansion of manufacturing operations, technological innovation in mixing technology, and the necessity for productive processing are central drivers that promote the expanding Australia industrial mixers and agitators market share.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2024 |

|

Forecast Years

|

2025-2033

|

|

Historical Years

|

2019-2024

|

| Market Size in 2024 | USD 89.60 Million |

| Market Forecast in 2033 | USD 191.66 Million |

| Market Growth Rate 2025-2033 | 7.90% |

Australia Industrial Mixers and Agitators Market Trends:

Integration of Automation and Smart Technologies

The infusion of automation and intelligent technologies into industrial mixers and agitators is a major trend in the Australian market. Manufacturing companies are increasingly turning towards automated equipment that is integrated with real-time monitoring, predictive maintenance, and remote operation functionalities. These technologies make it possible to have exact control over the mixing process, minimize human intervention errors, and enhance overall process efficiency. The integration of Internet of Things (IoT) connectivity makes data transfer between mixers and other machinery seamless, enabling optimized use of resources and minimizing downtime during production. As companies compete to achieve increased productivity and lower operational expenses, the need for smart and automated mixing systems is likely to keep fueling the Australia industrial mixers and agitators market growth. For instance, INOXPA offers DINAMIX SMX side-entry agitator range, which is an adaptable, modular system for process and storage tanks in industries like food, pharmaceuticals, and cosmetics. Designed for low-viscosity products, the agitator ensures efficient homogenization with adjustable power ratings. Key features include stainless steel construction, hygienic design, and ATEX certification.

To get more information on this market, Request Sample

Customization to Meet Industry-Specific Requirements

industrial mixers and agitators industry is fueled by the unique and varied requirements of different industries. Industries like food and beverage, pharmaceuticals, and chemicals have specific processing conditions in terms of viscosity, temperature, and material compatibility, which demand mixers and agitators with corresponding customized design and development. To meet this need, manufacturers are coming up with bespoke solutions that meet the specific requirement, ensuring maximum performance and adherence to industry standards. For instance, Teralba Industries, based in Australia, is a leading manufacturer of mixers, agitators, and heat exchangers for the food processing sector. Its key brands, namely Mixquip®, Dimpleflo, Accutherm, and Rummager®, offer solutions for various fluid mixing needs, from low-viscosity liquids to high-viscosity food products. Teralba emphasizes customisation, innovative mixing technologies, and hygienic designs like CIP heaters and pasteurisers. This move towards customization not only improves process efficiency and product quality but also enhances the competitive position of businesses within the market. With industries on the lookout for specialized mixing solutions, the demand for customized mixers and agitators is expected to propel the growth of the Australia industrial mixers and agitators market.

Australia Industrial Mixers and Agitators Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the country/regional level for 2025-2033. Our report has categorized the market based on type and application.

Type Insights:

- Top Entry Agitator and Mixer

- Side Entry Agitator and Mixer

- Bottom Entry Agitator and Mixer

- Others

The report has provided a detailed breakup and analysis of the market based on the type. This includes top entry agitator and mixer, side entry agitator and mixer, bottom entry agitator and mixer, and others.

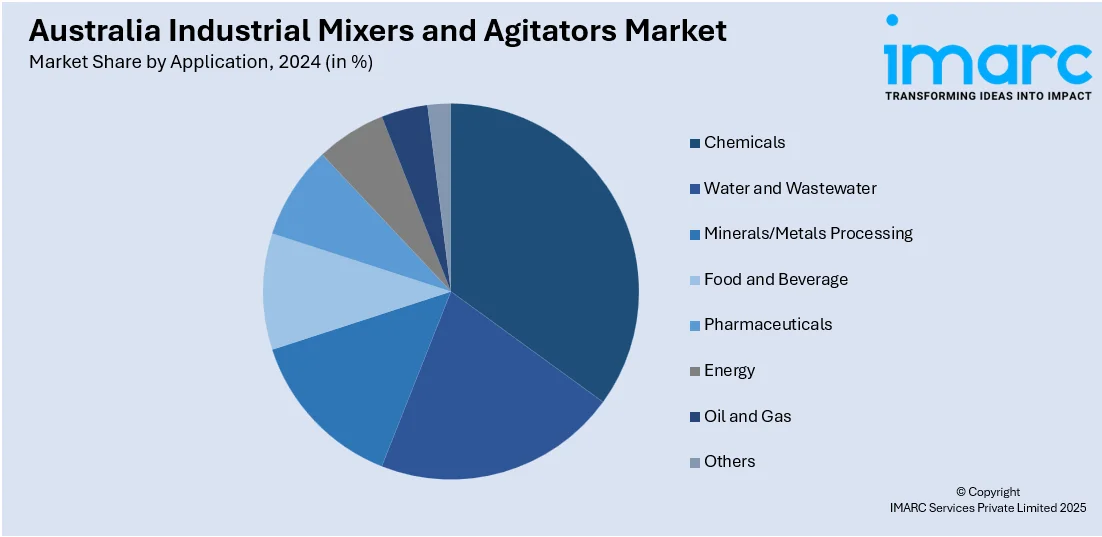

Application Insights:

- Chemicals

- Water and Wastewater

- Minerals/Metals Processing

- Food and Beverage

- Pharmaceuticals

- Energy

- Oil and Gas

- Others

A detailed breakup and analysis of the market based on the application have also been provided in the report. This includes chemicals, water and wastewater, minerals/metals processing, food and beverage, pharmaceuticals, energy, oil and gas, and others.

Regional Insights:

- Australia Capital Territory & New South Wales

- Victoria & Tasmania

- Queensland

- Northern Territory & Southern Australia

- Western Australia

The report has also provided a comprehensive analysis of all the major regional markets, which include Australia Capital Territory & New South Wales, Victoria & Tasmania, Queensland, Northern Territory & Southern Australia, and Western Australia.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

Australia Industrial Mixers and Agitators Market News:

- In March 2025, Pure Hydrogen secured a landmark order from Heidelberg Materials Australia for the country’s first hydrogen fuel cell (HFC) concrete agitator truck, set for Q4 2025 delivery. The T30-200 truck, featuring a 200kW Ballard fuel cell and CATL battery, offers over 200 km range and advanced safety features. This initiative aligns with Heidelberg’s 2030 sustainability goals.

- In June 2024, Tetra Pak, a leading provider of food packaging and processing solutions, launched an industrial agitator/mixer specifically designed to reduce foam formation during the mixing of liquid food products.

Australia Industrial Mixers and Agitators Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2024 |

| Historical Period | 2019-2024 |

| Forecast Period | 2025-2033 |

| Units | Million USD |

| Scope of the Report |

Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Types Covered | Top Entry Agitator and Mixer, Side Entry Agitator and Mixer, Bottom Entry Agitator and Mixer, Others |

| Applications Covered | Chemicals, Water and Wastewater, Minerals/Metals Processing, Food and Beverage, Pharmaceuticals, Energy, Oil and Gas, Others |

| Regions Covered | Australia Capital Territory & New South Wales, Victoria & Tasmania, Queensland, Northern Territory & Southern Australia, Western Australia |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the Australia industrial mixers and agitators market performed so far and how will it perform in the coming years?

- What is the breakup of the Australia industrial mixers and agitators market on the basis of type?

- What is the breakup of the Australia industrial mixers and agitators market on the basis of application?

- What is the breakup of the Australia industrial mixers and agitators market on the basis of region?

- What are the various stages in the value chain of the Australia industrial mixers and agitators market?

- What are the key driving factors and challenges in the Australia industrial mixers and agitators market?

- What is the structure of the Australia industrial mixers and agitators market and who are the key players?

- What is the degree of competition in the Australia industrial mixers and agitators market?

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the Australia industrial mixers and agitators market from 2019-2033.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the Australia industrial mixers and agitators market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the Australia industrial mixers and agitators industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)