Australia Propylene Oxide Market Size, Share, Trends and Forecast by Production Process, Application, End Use Industry, and Region, 2025-2033

Australia Propylene Oxide Market Overview:

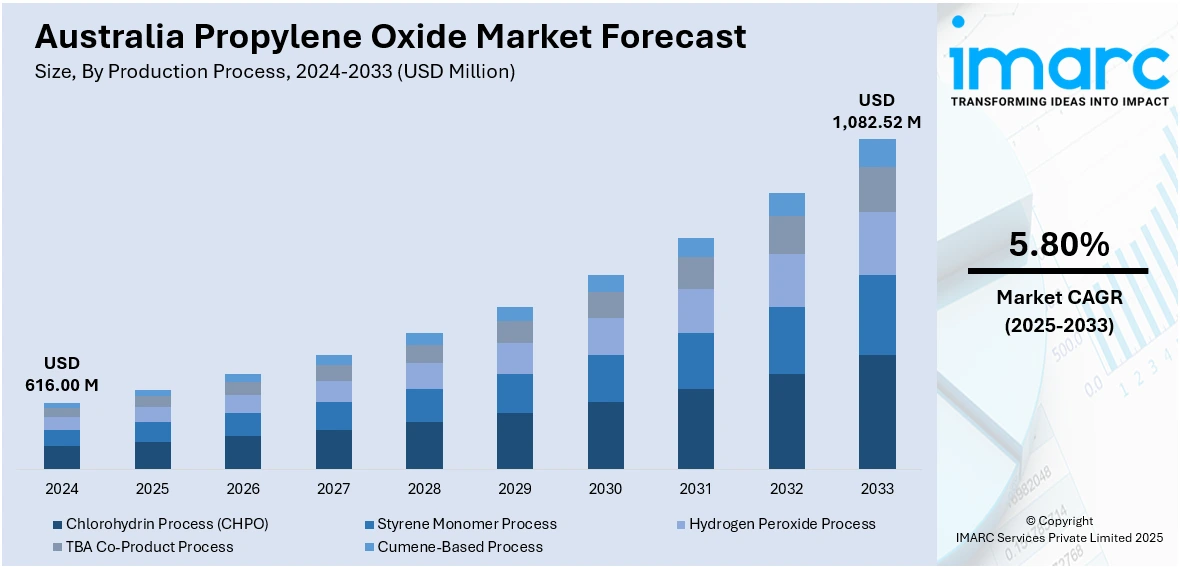

The Australia propylene oxide market size reached USD 616.00 Million in 2024. Looking forward, IMARC Group expects the market to reach USD 1,082.52 Million by 2033, exhibiting a growth rate (CAGR) of 5.80% during 2025-2033. The market is driven by rising demand from the polyurethane sector, particularly in construction and automotive industries. Sustainable building practices and energy-efficient vehicle trends further enhance consumption. Additionally, increasing adoption of bio-based production methods, supported by environmental regulations and green chemistry incentives, is expanding the Australia propylene oxide market share. Technological advancements in manufacturing also enhance supply efficiency, supporting long-term expansion.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2024

|

|

Forecast Years

|

2025-2033

|

|

Historical Years

|

2019-2024

|

| Market Size in 2024 | USD 616.00 Million |

| Market Forecast in 2033 | USD 1,082.52 Million |

| Market Growth Rate 2025-2033 | 5.80% |

Australia Propylene Oxide Market Trends:

Increasing Demand for Propylene Oxide in Polyurethane Production

The market is experiencing significant growth due to rising demand for polyurethane products across various industries. Propylene oxide is a key raw material used in manufacturing polyols, which are essential for producing polyurethane foams. These foams are widely utilized in construction, automotive, and furniture sectors for insulation, cushioning, and lightweight materials. As per a research report released by the IMARC Group, the market size for polyols in Australia was valued at USD 826.0 Million in 2024. It is projected to grow to USD 1,451.6 Million by 2033, reflecting a compound annual growth rate (CAGR) of 5.8% from 2025 to 2033. The growth of the Australian construction industry and the shift of the auto industry into fuel-efficient vehicles are driving the demand for high-quality polyurethane products. Along with this, government policies favoring green building practices are raising the demand to source environmentally friendly PU insulation and this is increasing propylene oxide demand. Manufacturers are putting money into new manufacturing technologies to help with their productivity and ensure supply for the expanding market since industries continue to seek long-lasting and sustainable materials. The Australian propylene oxide market will continue on its trend upward.

To get more information on this market, Request Sample

Shift Towards Bio-Based Propylene Oxide Production

The increasing shift toward bio-based production methods to meet environmental regulations and consumer demand for sustainable chemicals is favoring the Australia propylene oxide market growth. Traditional processes for manufacturing propylene oxide rely on petroleum processes and are subject to the release of carbon emissions. Therefore, most companies search for more environmentally friendly alternatives, such as bio-propylene oxide from sustainable and renewable sources, including biomass and vegetable oils. Australia is seeking to achieve its carbon targets in accordance with sustainability objectives. Chemical manufacturers are, therefore, considering sustainable processes. On 27th February’2025, $10.4 million has been committed to projects that turn sugarcane waste into fuel in Australia. That includes $8 million for Licella’s proposed biorefinery in Queensland, which is expected to produce 60 million litres of low-carbon fuel each year and $2.4 million to help Viva Energy establish sustainable aviation fuel (SAF) infrastructure at Brisbane Airport. With funding from ARENA, these projects will help to progress Australia's net-zero emissions targets at the same time as revolutionizing the bio based alternatives sectors by utilizing agricultural waste. This program is a component of a wider $33.5 million national push to decarbonize the sectors using groundbreaking sustainable waste-to-energy technologies. Additionally, bio-based propylene oxide offers comparable performance with the added appeal to industries that value sustainability, including packaging and textiles. Government incentives also further encourage green chemistry concepts, and this shift brings focus to bio-refineries and sustainable manufacturing facilities. In the present context of environmental consciousness, greater adoption of bio-based propylene oxide will assist in transforming the market landscape while guiding long-term environmental results.

Australia Propylene Oxide Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the country and regional levels for 2025-2033. Our report has categorized the market based on production process, application, and end use industry.

Production Process Insights:

- Chlorohydrin Process (CHPO)

- Styrene Monomer Process

- Hydrogen Peroxide Process

- TBA Co-Product Process

- Cumene-Based Process

The report has provided a detailed breakup and analysis of the market based on the production process. This includes chlorohydrin process (CHPO), styrene monomer process, hydrogen peroxide process, TBA co-product process, and cumene-based process.

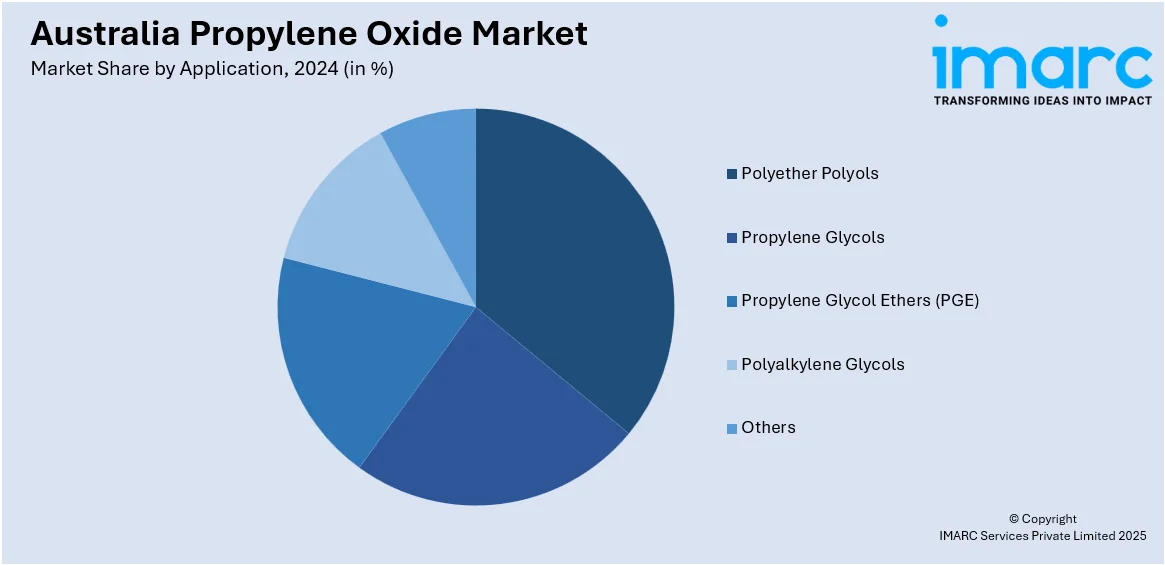

Application Insights:

- Polyether Polyols

- Propylene Glycols

- Propylene Glycol Ethers (PGE)

- Polyalkylene Glycols

- Others

A detailed breakup and analysis of the market based on the application have also been provided in the report. This includes polyether polyols, propylene glycols, propylene glycol ethers (PGE), polyalkylene glycols, and others.

End Use Industry Insights:

- Automotive

- Construction

- Chemicals and Pharmaceuticals

- Packaging

- Textile and Furnishing

- Others

The report has provided a detailed breakup and analysis of the market based on the end use industry. This includes automotive, construction, chemicals and pharmaceuticals, packaging, textile and furnishing, and others.

Regional Insights:

- Australia Capital Territory & New South Wales

- Victoria & Tasmania

- Queensland

- Northern Territory & Southern Australia

- Western Australia

The report has also provided a comprehensive analysis of all the major regional markets, which include Australia Capital Territory & New South Wales, Victoria & Tasmania, Queensland, Northern Territory & Southern Australia, and Western Australia.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

Australia Propylene Oxide Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2024 |

| Historical Period | 2019-2024 |

| Forecast Period | 2025-2033 |

| Units | Million USD |

| Scope of the Report |

Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Production Processes Covered | Chlorohydrin Process (CHPO), Styrene Monomer Process, Hydrogen Peroxide Process, TBA Co-Product Process, Cumene-Based Process |

| Applications Covered | Polyether Polyols, Propylene Glycols, Propylene Glycol Ethers (PGE), Polyalkylene Glycols, Others |

| End Use Industries Covered | Automotive, Construction, Chemicals and Pharmaceuticals, Packaging, Textile and Furnishing, Others |

| Regions Covered | Australia Capital Territory & New South Wales, Victoria & Tasmania, Queensland, Northern Territory & Southern Australia, Western Australia |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the Australia propylene oxide market performed so far and how will it perform in the coming years?

- What is the breakup of the Australia propylene oxide market on the basis of production process?

- What is the breakup of the Australia propylene oxide market on the basis of application?

- What is the breakup of the Australia propylene oxide market on the basis of end use industry?

- What is the breakup of the Australia propylene oxide market on the basis of region?

- What are the various stages in the value chain of the Australia propylene oxide market?

- What are the key driving factors and challenges in the Australia propylene oxide?

- What is the structure of the Australia propylene oxide market and who are the key players?

- What is the degree of competition in the Australia propylene oxide market?

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the Australia propylene oxide market from 2019-2033.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the Australia propylene oxide market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the Australia propylene oxide industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)