Brazil Automotive Wiring Harness Market Size, Share, Trends and Forecast by Application, Material Type, Transmission Type, Vehicle Type, Category, Component, and Region, 2025-2033

Brazil Automotive Wiring Harness Market Overview:

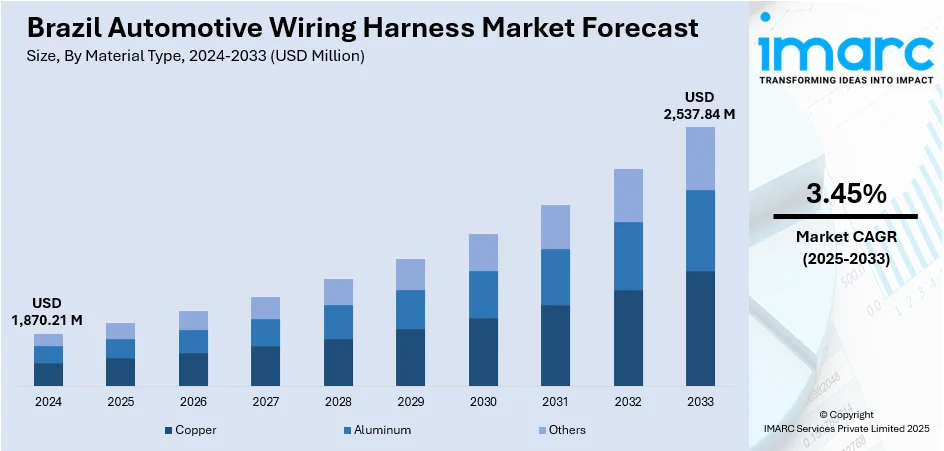

The Brazil automotive wiring harness market size reached USD 1,870.21 Million in 2024. Looking forward, the market is expected to reach USD 2,537.84 Million by 2033, exhibiting a growth rate (CAGR) of 3.45% during 2025-2033. The market is growing, driven by rising local production and electrification. Demand spans engine, lighting, HVAC, and EV powertrains. Lightweight materials and evolving wiring for high-voltage, safety, and connectivity features fuel growth. Domestic manufacturing, OEM ties, and aftermarket expansion enhance supply and Brazil automotive wiring harness market share.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2024

|

|

Forecast Years

|

2025-2033

|

|

Historical Years

|

2019-2024

|

| Market Size in 2024 | USD 1,870.21 Million |

| Market Forecast in 2033 | USD 2,537.84 Million |

| Market Growth Rate 2025-2033 | 3.45% |

Brazil Automotive Wiring Harness Market Trends:

Electrification and Advanced Wiring Architecture

In February 2025, Brazil’s National Association of Automotive Vehicle Manufacturers (ANFAVEA) confirmed that 217,400 vehicles were produced, marking the strongest February showing in several years. As domestic production strengthens, demand for more sophisticated wiring harnesses is growing especially in vehicles integrating hybrid or electric drivetrains. Harness systems are being reengineered to support higher-voltage lines, multiplex data routing, and sensitive components like radar, cameras, and battery management modules. Designers are prioritizing materials that balance conductivity and weight, including copper-aluminum hybrids and halogen-free insulators. Modular harness architecture is also gaining traction, reducing the number of connectors and simplifying in-vehicle routing. These systems not only improve performance but also cut installation time and reduce maintenance complexity. Government-backed support for EV development and local component integration is accelerating adoption of these upgraded harness systems. As Brazil’s mobility platforms evolve, the shift toward electric and connected vehicles is driving a measurable change in wiring demands. These factors collectively support long-term Brazil automotive wiring harness market growth as OEMs and suppliers respond to rising expectations for energy efficiency and digital integration.

To get more information on this market, Request Sample

Automation & Smart Manufacturing Adoption

In January 2025, total vehicle production in Brazil reached 175,541 units, marking a strong rebound compared to prior months and signaling growing plant activity. To keep up with rising output and complexity, harness assembly lines are embracing automation and digital integration. Robotic crimping cells are ensuring consistency across large connector volumes, while machine‑vision systems detect splice and connector misalignment in real time. Integrated inspection platforms linked to digital ERP systems enhance traceability and quality oversight. Modular assembly stations allow harness variants to be built in parallel, reducing cycle time for vehicle variants. This automation also enables scalable throughput across both conventional and electrified vehicle segments. As wiring complexity grows driven by expanded EV and hybrid architectures these smart manufacturing systems offer the precision and flexibility needed to ensure consistent, defect-free builds. In summary, this rise of factory automation and digitalized processes illustrates a central element of Brazil automotive wiring harness market trends in today’s evolving supply chain landscape.

Brazil Automotive Wiring Harness Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the country/regional level for 2025-2033. Our report has categorized the market based on application, material type, transmission type, vehicle type, category, and component.

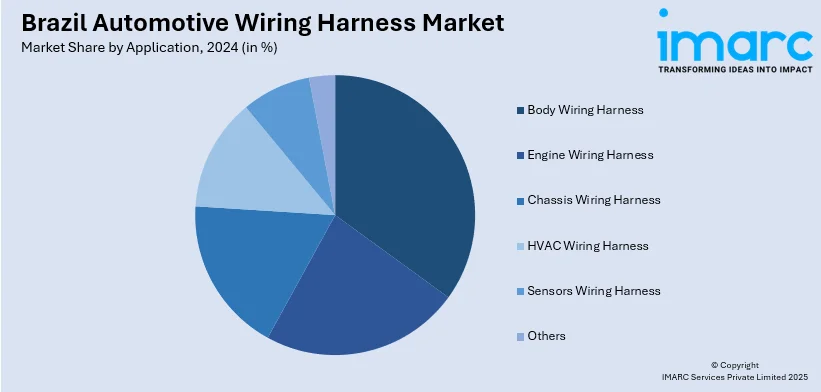

Application Insights:

- Body Wiring Harness

- Engine Wiring Harness

- Chassis Wiring Harness

- HVAC Wiring Harness

- Sensors Wiring Harness

- Others

The report has provided a detailed breakup and analysis of the market based on the application. This includes body wiring harness, engine wiring harness, chassis wiring harness, HVAC wiring harness, sensors wiring harness, and others.

Material Type Insights:

- Copper

- Aluminum

- Others

A detailed breakup and analysis of the market based on the material type have also been provided in the report. This includes copper, aluminum, and others.

Transmission Type Insights:

- Data Transmission

- Electrical Wiring

The report has provided a detailed breakup and analysis of the market based on the transmission type. This includes data transmission and electrical wiring.

Vehicle Type Insights:

- Two Wheelers

- Passenger Cars

- Commercial Vehicles

A detailed breakup and analysis of the market based on the vehicle type has also been provided in the report. This includes two wheelers, passenger cars, and commercial vehicles.

Category Insights:

- General Wires

- Heat Resistant Wires

- Shielded Wires

- Tubed Wires

The report has provided a detailed breakup and analysis of the market based on the category. This includes general wires, heat resistant wires, shielded wires, and tubed wires.

Component Insights:

- Connectors

- Wires

- Terminals

- Others

A detailed breakup and analysis of the market based on the component have also been provided in the report. This includes connectors, wires, terminals, and others.

Regional Insights:

- Southeast

- South

- Northeast

- North

- Central-West

The report has also provided a comprehensive analysis of all the major regional markets, which include Southeast, South, Northeast, North, and Central-West.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

Brazil Automotive Wiring Harness Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2024 |

| Historical Period | 2019-2024 |

| Forecast Period | 2025-2033 |

| Units | Million USD |

| Scope of the Report |

Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Applications Covered | Body Wiring Harness, Engine Wiring Harness, Chassis Wiring Harness, HVAC Wiring Harness, Sensors Wiring Harness, Others |

| Material Types Covered | Copper, Aluminum, Others |

| Transmission Types Covered | Data Transmission, Electrical Wiring |

| Vehicle Types Covered | Two Wheelers, Passenger Cars, Commercial Vehicles |

| Categories Covered | General Wires, Heat Resistant Wires, Shielded Wires, Tubed Wires |

| Components Covered | Connectors, Wires, Terminals, Others |

| Regions Covered | Southeast, South, Northeast, North, Central-West |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the Brazil automotive wiring harness market performed so far and how will it perform in the coming years?

- What is the breakup of the Brazil automotive wiring harness market on the basis of application?

- What is the breakup of the Brazil automotive wiring harness market on the basis of material type?

- What is the breakup of the Brazil automotive wiring harness market on the basis of transmission type?

- What is the breakup of the Brazil automotive wiring harness market on the basis of vehicle type?

- What is the breakup of the Brazil automotive wiring harness market on the basis of category?

- What is the breakup of the Brazil automotive wiring harness market on the basis of component?

- What is the breakup of the Brazil automotive wiring harness market on the basis of region?

- What are the various stages in the value chain of the Brazil automotive wiring harness market?

- What are the key driving factors and challenges in the Brazil automotive wiring harness market?

- What is the structure of the Brazil automotive wiring harness market and who are the key players?

- What is the degree of competition in the Brazil automotive wiring harness market?

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the Brazil automotive wiring harness market from 2019-2033.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the Brazil automotive wiring harness market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the Brazil automotive wiring harness industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)