Brazil Engineering Plastics Market Size, Share, Trends and Forecast by Product Type, Application, and Region, 2026-2034

Brazil Engineering Plastics Market Summary:

The Brazil engineering plastics market size was valued at USD 2.30 Million in 2025 and is projected to reach USD 4.22 Million by 2034, growing at a compound annual growth rate of 6.99% from 2026-2034.

The Brazil engineering plastics market is experiencing robust expansion driven by accelerating industrialization, automotive sector modernization, and surging demand for lightweight high-performance materials across diverse manufacturing applications. The market benefits from strategic foreign direct investments that enhance domestic production capabilities while introducing advanced polymer technologies. Growing emphasis on sustainable solutions and circular economy principles is catalyzing innovation in bio-based engineering plastics and advanced recycling technologies, positioning Brazil as an emerging leader in sustainable polymer development within Latin America.

Key Takeaways and Insights:

- By Product Type: Styrene copolymers (ABS & SAN) dominated the market with 18% share in 2025, driven by extensive utilization in automotive interior components, consumer electronics housings, and household appliance manufacturing, where superior impact resistance and aesthetic versatility are paramount requirements.

- By Application: Automotive and transportation leads the market with a share of 25% in 2025, propelled by intensifying demand for lightweight materials to enhance fuel efficiency and meet stringent emission regulations as vehicle manufacturers prioritize weight reduction strategies.

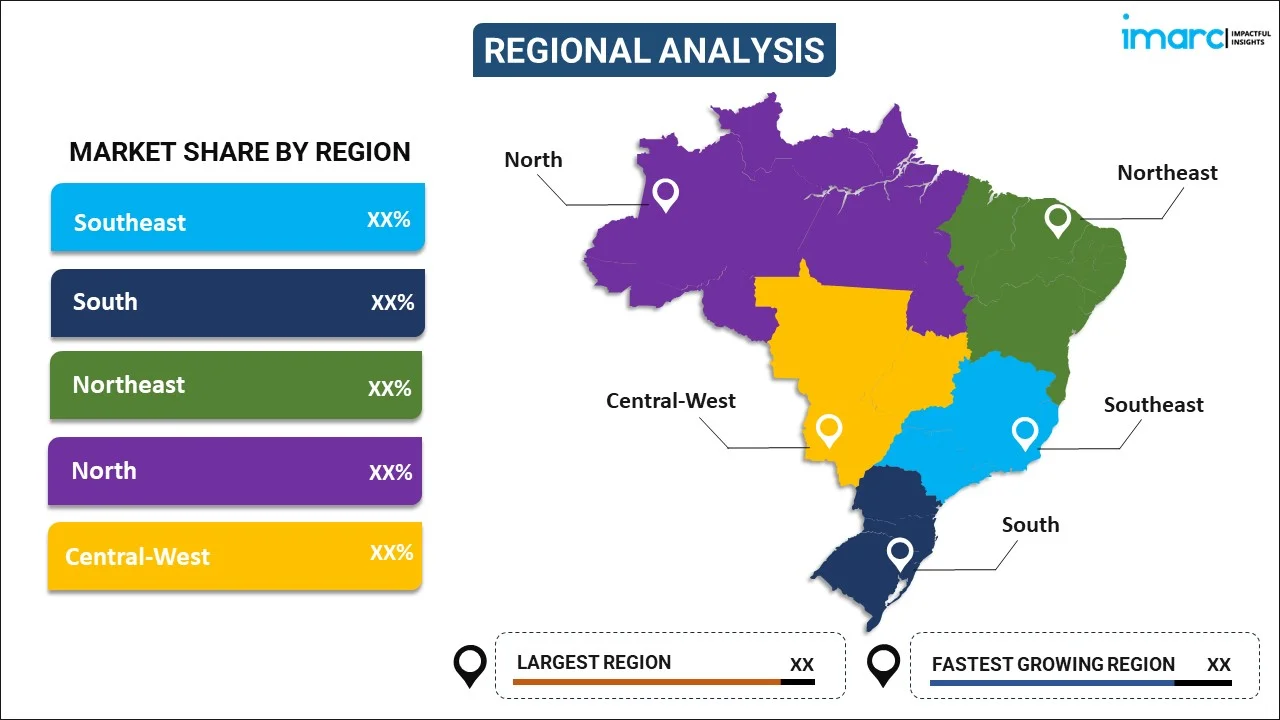

- By Region: Southeast represents the largest segment with a market share of 38% in 2025, attributable to the concentration of automotive manufacturing facilities, electronics production hubs, and industrial infrastructure in São Paulo and surrounding industrial corridors.

- Key Players: The Brazil engineering plastics market exhibits moderate competitive intensity, characterized by the presence of established multinational chemical corporations alongside regional polymer processors. Market participants compete through product innovation, technical service capabilities, and strategic partnerships to capture evolving demand across automotive, electronics, and construction sectors.

Engineering plastics represent a category of high-performance thermoplastic materials distinguished by superior mechanical strength, thermal stability, and chemical resistance compared to commodity polymers. These materials encompass polyamides, polycarbonates, polyacetals, fluoropolymers, and styrene copolymers, finding extensive application in precision components for automotive, electrical, aerospace, and medical device manufacturing. The Brazil market is witnessing transformational growth as industrial modernization accelerates material substitution from traditional metals to advanced engineering polymers. In October 2024, Dow and Ambipar announced a strategic partnership to expand polyethylene recycling capacity from 2,000 tons to 60,000 tons annually by 2030, establishing Brazil's first integrated circular economy center for polyethylene plastics and demonstrating the market's evolution toward sustainable polymer solutions.

Brazil Engineering Plastics Market Trends:

Acceleration of Bio-Based Engineering Plastics Development

The Brazilian market is witnessing substantial momentum in bio-based engineering plastics as sustainability imperatives reshape material selection across industries. Manufacturers are increasingly developing polymers derived from renewable feedstocks, particularly sugarcane-based bioethanol, leveraging Brazil's agricultural prowess. Braskem, the world's leading biopolymer producer, currently manufactures nearly 200,000 tons of biopolymers annually in Brazil with plans to expand capacity to 260,000 tons and reach one million tons by 2030, reflecting the transformational shift toward renewable polymer sources.

Advanced Recycling Technologies Driving Circular Economy

Chemical and mechanical recycling technologies are rapidly progressing in Brazil, allowing post-consumer plastic waste to be converted into high-quality engineering resins. Advanced recycling methods complement traditional mechanical processes by handling materials that are difficult to recycle and producing outputs with properties comparable to virgin polymers. These developments support the circular economy by enabling plastics to re-enter the value chain, reducing reliance on new raw materials, minimizing environmental impact, and promoting sustainable production practices across industries that utilize high-performance polymer materials.

Electric Vehicle Adoption Catalyzing Specialty Polymer Demand

The emergence of electric vehicles in Brazil is generating substantial demand for specialized engineering plastics with enhanced thermal management and electrical insulation properties. Lightweight polymer components are critical for extending vehicle range, while battery housings require materials combining impact resistance with flame retardancy. In the state of São Paulo, the former Mercedes-Benz manufacturing facility in Iracemápolis has been taken over by Chinese automaker GWM. The company has announced plans to commit significant long-term investment at the site through 2032, reinforcing its strategy to expand local production capabilities and strengthen its presence in the Brazilian automotive market. This is directly stimulating demand for advanced engineering plastics in next-generation mobility applications.

Market Outlook 2026-2034:

The outlook for Brazil’s engineering plastics market remains favorable over the forecast period, supported by steady industrial growth, ongoing modernization within the automotive sector, and expanding electronics manufacturing activities. Rising adoption of advanced materials across multiple industries is strengthening demand for high-performance plastics. In addition, government policies promoting local manufacturing, together with increasing foreign direct investment, are improving production capacity and encouraging technology transfer. These factors are collectively creating a robust foundation for long-term market growth and supporting the development of more sophisticated manufacturing capabilities across the country. The market generated a revenue of USD 2.30 Million in 2025 and is projected to reach a revenue of USD 4.22 Million by 2034, growing at a compound annual growth rate of 6.99% from 2026-2034.

Brazil Engineering Plastics Market Report Segmentation:

| Segment Category | Leading Segment | Market Share |

|---|---|---|

| Product Type | Styrene Copolymers (ABS & SAN) | 18% |

| Application | Automotive and Transportation | 25% |

| Region | Southeast | 38% |

Product Type Insights:

To get detailed segment analysis of this market Request Sample

- Fluoropolymers

- Polycarbonate (PC)

- Polyethylene Terephthalate (PET)

- Polybutylene Terephthalate (PBT)

- Polyacetal/ Polyoxymethylene

- Polymethyl Methacrylate (PMMA)

- Polyphenylene Oxide

- Polyphenylene Sulfide (PPS)

- Styrene Copolymers (ABS and SAN)

- Liquid Crystal Polymers (LCP)

- Polyether Ether Ketone (PEEK)

- Polyimides (PI)

- Polyamides

Styrene copolymers (ABS & SAN) dominate with a market share of 18% of the total Brazil engineering plastics market in 2025.

Styrene copolymers, encompassing acrylonitrile butadiene styrene (ABS) and styrene acrylonitrile (SAN), command the largest product type share driven by their exceptional combination of mechanical properties, processability, and cost-effectiveness. These versatile materials offer superior impact resistance, dimensional stability, and aesthetic finish quality, making them indispensable for automotive interior components, consumer electronics housings, and household appliance manufacturing. The segment benefits from Brazil's robust appliance manufacturing sector and expanding automotive production.

Demand for styrene copolymers continues to strengthen as electronics manufacturers require materials combining electrical insulating properties with design flexibility for compact device housings. The automotive sector's emphasis on interior aesthetics and lightweight components further reinforces segment growth. Brazilian automotive production reached 2.549 million units in 2024, representing a 9.7% increase over the previous year, directly stimulating demand for ABS in dashboards, interior trim panels, and decorative components where surface quality and impact performance are critical requirements.

Application Insights:

- Automotive and Transportation

- Building and Construction

- Consumer Goods

- Electrical and Electronics

- Industrial and Machinery

- Packaging

- Medical

Automotive and transportation leads with a share of 25% of the total Brazil engineering plastics market in 2025.

The automotive and transportation segment maintains market leadership driven by intensifying demand for lightweight materials that enhance fuel efficiency and support emission reduction objectives. Engineering plastics enable weight reductions of up to forty percent compared to metal alternatives while maintaining structural integrity and design flexibility. Brazilian automotive manufacturers are progressively substituting metal components with high-performance polymers in bumper systems, under-hood applications, interior trim, and structural elements.

The segment benefits strongly from Brazil’s established position as a major global automotive manufacturing hub, supported by the presence of leading vehicle producers with extensive local operations. The ongoing shift toward electric and hybrid vehicles is accelerating the use of specialty engineering plastics in applications such as battery enclosures, thermal management systems, and lightweight structural parts. Continued investment in plant modernization and vehicle electrification is expected to sustain healthy demand growth, reinforcing the automotive sector’s role as a key driver for engineering plastics consumption over the forecast period.

Regional Insights:

To get detailed regional analysis of this market Request Sample

- Southeast

- South

- Northeast

- North

- Central-West

Southeast exhibits clear dominance with a 38% share of the total Brazil engineering plastics market in 2025.

The Southeast region commands the largest market share attributable to the concentration of automotive manufacturing facilities, electronics production operations, and industrial infrastructure centered in São Paulo and surrounding economic corridors. São Paulo state alone accounts for over forty-one percent of Brazil's automotive manufacturing complex, establishing the region as the primary demand center for engineering plastics. The presence of major polymer producers, compounders, and processing facilities ensures efficient supply chain integration.

Regional advantages include proximity to major port facilities enabling raw material imports and finished goods exports, along with established technical service networks supporting end-user applications. The concentration of research institutions and technical universities facilitates innovation in polymer applications and processing technologies. Ongoing infrastructure investments and industrial modernization programs continue reinforcing the Southeast's position as Brazil's engineering plastics consumption hub.

Market Dynamics:

Growth Drivers:

Why is the Brazil Engineering Plastics Market Growing?

Expanding Automotive Sector and Lightweighting Initiatives

The automotive sector serves as a key growth driver as manufacturers increasingly focus on reducing vehicle weight and improving fuel efficiency. Engineering plastics provide clear advantages over traditional metal components, offering high strength with substantial weight reduction, resistance to corrosion, greater design flexibility, and more cost-efficient manufacturing processes. As vehicle production continues to recover and manufacturers invest in modernization and electrification, the substitution of metal parts with engineering polymers is gaining momentum. This shift is evident across structural, interior, and under-the-hood applications, supporting broader adoption of advanced plastic materials in automotive design.

Robust Electronics and Appliance Manufacturing Growth

Brazil’s electronics and appliance manufacturing sectors are undergoing strong expansion, creating steady demand for engineering plastics that offer excellent electrical insulation, dimensional stability, and visual appeal. Growth across consumer electronics and household appliances is reinforcing the need for high-performance materials used in durable and precision components. Engineering plastics such as polycarbonates, polyamides, and styrene-based polymers play a critical role in applications including casings, connectors, and structural parts. Their versatility and performance characteristics make them indispensable across home appliances, consumer electronics, and a wide range of industrial electrical equipment.

Infrastructure Development and Construction Activity

Accelerating infrastructure development and construction activity is generating expanding applications for engineering plastics in building materials, piping systems, and architectural components. Brazil construction market size reached USD 156.0 Billion in 2025. Looking forward, IMARC Group expects the market to reach USD 218.2 Billion by 2034, exhibiting a growth rate (CAGR) of 3.80% during 2026-2034. Government infrastructure and housing initiatives are driving demand for engineering plastics across construction and public utility projects. These materials are valued for their durability, corrosion resistance, and design flexibility in applications such as pipes, fittings, insulation, and structural components. Ongoing infrastructure development and residential construction activity continue to support steady consumption of construction-grade polymer materials in Brazil.

Market Restraints:

What Challenges the Brazil Engineering Plastics Market is Facing?

Environmental Concerns and Regulatory Pressures

Increasing environmental awareness is enhancing the questioning of the use and disposal processes of plastics, which may limit market growth. Laws on plastic waste disposal, recycling demands, and environmental effects are changing, and burden manufacturers with compliance costs as consumers shift to sustainable sources. Biodegradable and bio-based engineering plastics are still under development and scale, in a slower way than is necessary to totally meet the environmental concern.

Raw Material Price Volatility and Supply Chain Dependencies

The manufacture of plastics is an engineering process that depends on petrochemical raw materials, which are highly sensitive to price fluctuations affecting the market of crude oil, geopolitical factors, and global supply-demand dynamics. The externality of Brazil on the imports of some specialty grades of polymer subjects local markets to currency exchange risk and global supply shocks. These factors complicate procurement planning and pricing strategies for processors and end-users throughout the value chain.

Limited Skilled Workforce and Technical Capabilities

The engineering plastics industry requires specialized technical expertise in polymer processing, application engineering, and quality assurance that remains constrained in the Brazilian market. Limited availability of trained personnel can impede manufacturing efficiency, product development capabilities, and technical service delivery. Workforce development efforts are progressing but may not keep pace with accelerating market demand and technological complexity.

Competitive Landscape:

The Brazil engineering plastics market exhibits moderate competitive intensity characterized by the presence of established multinational chemical corporations alongside regional polymer processors and compounders. Major international players leverage vertically integrated feedstock positions, extensive product portfolios, and global technical resources to serve demanding applications across automotive, electronics, and industrial sectors. Competition centers on product performance differentiation, technical service capabilities, supply reliability, and sustainability credentials. Strategic partnerships between resin producers and recycling operators are proliferating as circular economy imperatives reshape competitive dynamics. Market participants are investing in local technical service infrastructure and application development capabilities to capture evolving customer requirements, while sustainability-focused innovation is becoming an increasingly important competitive differentiator.

Recent Developments:

- June 2024: Trinseo introduced three new recycled-content resins containing up to sixty percent chemically recycled styrene for ABS and SAN applications across automotive, industrial, and consumer segments, offering equivalent performance to conventional grades while reducing carbon footprint by approximately eighteen percent.

Brazil Engineering Plastics Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2025 |

| Historical Period | 2020-2025 |

| Forecast Period | 2026-2034 |

| Units | Million USD |

| Scope of the Report | Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Product Types Covered | Fluoropolymers, Polycarbonate (PC), Polyethylene Terephthalate (PET), Polybutylene Terephthalate (PBT), Polyacetal/ Polyoxymethylene, Polymethyl Methacrylate (PMMA), Polyphenylene Oxide, Polyphenylene Sulfide (PPS), Styrene Copolymers (ABS & SAN), Liquid Crystal Polymers (LCP), Polyether Ether Ketone (PEEK), Polyimides (PI), Polyamides |

| Applications Covered | Automotive and Transportation, Building and Construction, Consumer Goods, Electrical and Electronics, Industrial and Machinery, Packaging, Medical |

| Regions Covered | Southeast, South, Northeast, North, Central-West |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 9-11 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report

The Brazil engineering plastics market size was valued at USD 2.30 Million in 2025.

The Brazil engineering plastics market is expected to grow at a compound annual growth rate of 6.99% from 2026-2034 to reach USD 4.22 Million by 2034.

Styrene Copolymers (ABS & SAN) dominated the product type segment with an 18% market share in 2025, driven by extensive application in automotive interior components, consumer electronics housings, and household appliance manufacturing where impact resistance and aesthetic versatility are essential requirements.

Key factors driving the Brazil engineering plastics market include expanding automotive production and lightweighting initiatives, robust electronics and appliance manufacturing growth, accelerating infrastructure development and construction activity, rising foreign direct investments enhancing production capabilities, and growing adoption of sustainable and bio-based polymer solutions.

Major challenges include intensifying environmental concerns and regulatory pressures regarding plastic waste management, raw material price volatility and supply chain dependencies affecting production costs, limited availability of skilled workforce for specialized polymer processing applications, and competition from alternative materials in certain end-use segments.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)