Broccoli and Cheese Bites Manufacturing Plant Project Report 2026: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue

Report Overview:

IMARC Group’s report, titled “Broccoli and Cheese Bites Manufacturing Plant Project Report 2026: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue,” provides a complete roadmap for setting up a broccoli and cheese bites manufacturing plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc. The broccoli and cheese bites project report provides detailed insights into project economics, including capital investments, project funding, operating expenses, income and expenditure projections, fixed costs vs. variable costs, direct and indirect costs, expected ROI and net present value (NPV), profit and loss account, financial analysis, etc.

Broccoli and Cheese Bites Market Analysis:

The worldwide market for meal kit delivery services was valued at US$ 24.8 Billion in 2023. In the future, the IMARC Group predicts that the market will grow to US$ 85.0 Billion by 2032, reporting a compound annual growth rate (CAGR) of 14.7% from 2024 to 2032. Broccoli and cheese bites are gaining popularity among health-conscious consumers and consequently integrated in the meal kit and dietary plan services. These services aim to make meal preparation easier by ensuring both nutritional balance and delicious flavors. Broccoli and cheese bites are a good fit in this framework because they are convenient and offer health benefits. They are frequently included in meal packages that help achieve certain dietary objectives like increasing vegetable intake, following low-carb diets, or offering fast and healthy meal choices for families. Incorporating these into meal kits not only satisfies the desire for nutritious, convenient foods but also improves the diversity and attractiveness of the meal plans provided. This addition effectively accommodates the hectic schedules of contemporary customers, simplifying the task of upholding a healthy diet without sacrificing flavor or food excellence.

Broccoli and Cheese Bites Market Trends:

Health and Convenience Trends

The increasing demand for healthier snack choices among health-conscious individuals is bolstering the market growth. Broccoli is well-known for its high content of important nutrients such as vitamins and dietary fiber, providing major health advantages. Paired with cheese that improves the taste, these bites appeal to various people, especially those who prioritize their health. Additionally, the demand for broccoli and cheese bites is also driven by the growing need for convenient and easily prepared foods. As lifestyles are becoming busier, consumers are increasingly seeking quick, hassle-free meal solutions. Broccoli and cheese bites fit this need perfectly as they are ready-to-eat (RTE) and require minimal preparation time. This blend of health benefits and convenience aligns with the desires of modern consumers who prioritize nutritious yet easy meal options. Blue Apron expanded its ready-to-eat category with the launch of Prepared & Ready meals, available for shipment starting January 8, 2024.

Marketing and Distribution Innovations

Promoting the nutritional advantages and convenience of snacks is greatly increasing consumer knowledge and interest due to successful marketing tactics. Utilizing digital marketing and social media campaigns is playing a key role in reaching a wider audience, especially with the rise of online shopping. Additionally, the presence of these products on online grocery platforms and health-focused retail stores is leading to higher availability, making them more accessible to consumers. The rising popularity of e-commerce platforms is enabling companies to access international markets with greater efficiency. In 2023, the size of the worldwide e-commerce market hit US$ 21.1 Trillion. In the upcoming years, the IMARC Group anticipates the market to achieve a value of US$ 183.8 Trillion by 2032. These crucial marketing and distribution strategies are necessary to drive sales and expand the market reach of broccoli and cheese bites, meeting the changing shopping habits of consumers.

Latest Industry News:

The market is also being driven by increasing investments and capacity expansions:

- November 2023: Gordon Ramsay introduced his new frozen food collection at Walmart, which includes a range of starters and main courses perfect for simple meals, gatherings, and festive occasions. The selection featured options like Cheese Bites, Crab Cakes, Lasagna, and Shepherd’s Pie.

- March 2023: During Expo West 2023, Brazi Bites unveiled their new Everything cheese bites, while Alexia introduced Cauliflower & Broccoli Au Gratin bites with Red Chili Flakes. Both advancements broadened their selections with distinctive, tasty choices.

The following aspects have been covered in the broccoli and cheese bites manufacturing plant report:

- Market Analysis:

- Market Trends

- Market Breakup by Segment

- Market Breakup by Region

- Price Analysis

- Impact of COVID-19

- Market Forecast

The report provides insights into the landscape of the broccoli and cheese bites industry at the global level. The report also provides a segment-wise and region-wise breakup of the global broccoli and cheese bites industry. Additionally, it also provides the price analysis of feedstocks used in the manufacturing of broccoli and cheese bites, along with the industry profit margins.

- Detailed Process Flow:

- Product Overview

- Unit Operations Involved

- Mass Balance and Raw Material Requirements

- Quality Assurance Criteria

- Technical Tests

The report also provides detailed information related to the broccoli and cheese bites manufacturing process flow and various unit operations involved in a manufacturing plant. Furthermore, information related to mass balance and raw material requirements has also been provided in the report with a list of necessary quality assurance criteria and technical tests.

- Project Details, Requirements and Costs Involved:

- Land, Location and Site Development

- Plant Layout

- Machinery Requirements and Costs

- Raw Material Requirements and Costs

- Packaging Requirements and Costs

- Transportation Requirements and Costs

- Utility Requirements and Costs

- Human Resource Requirements and Costs

The report provides a detailed location analysis covering insights into the land location, selection criteria, location significance, environmental impact, expenditure, and other broccoli and cheese bites manufacturing plant costs. Additionally, the report provides information related to plant layout and factors influencing the same. Furthermore, other requirements and expenditures related to machinery, raw materials, packaging, transportation, utilities, and human resources have also been covered in the report.

- Project Economics:

- Capital Investments

- Operating Costs

- Expenditure Projections

- Revenue Projections

- Taxation and Depreciation

- Profit Projections

- Financial Analysis

The report also covers a detailed analysis of the project economics for setting up a broccoli and cheese bites manufacturing plant. This includes the analysis and detailed understanding of broccoli and cheese bites manufacturing plant costs, including capital expenditure (CapEx), operating expenditure (OpEx), income projections, taxation, depreciation, liquidity analysis, profitability analysis, payback period, NPV, uncertainty analysis, and sensitivity analysis. Furthermore, the report also provides a detailed analysis of the regulatory procedures and approvals, information related to financial assistance, along with a comprehensive list of certifications required for setting up a broccoli and cheese bites manufacturing plant.

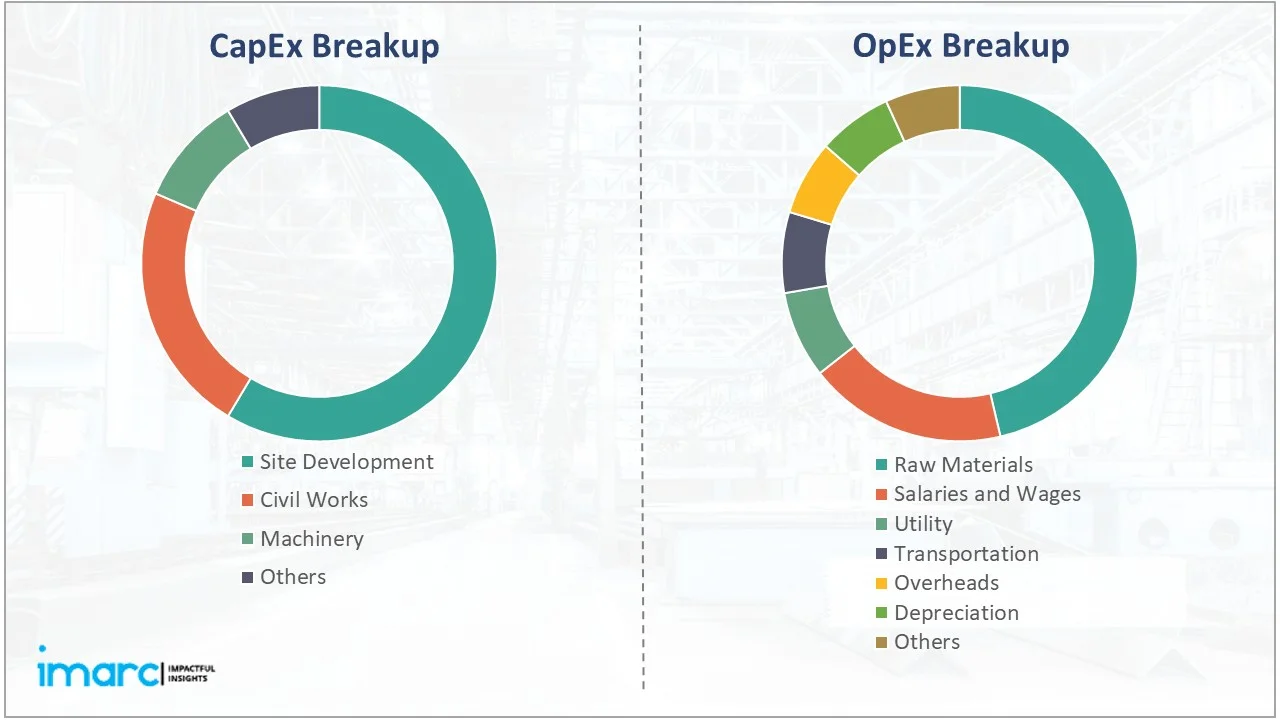

Capital Expenditure Breakdown:

| Particulars | Cost (in US$) |

|---|---|

| Land and Site Development Costs | XX |

| Civil Works Costs | XX |

| Machinery Costs | XX |

| Other Capital Costs | XX |

Operational Expenditure Breakdown:

| Particulars | In % |

|---|---|

| Raw Material Cost | XX |

| Utility Cost | XX |

| Transportation Cost | XX |

| Packaging Cost | XX |

| Salaries and Wages | XX |

| Depreciation | XX |

| Other Expenses | XX |

Profitability Analysis:

| Particulars | Unit | Year 1 | Year 2 | Year 3 | Year 4 | Year 5 |

|---|---|---|---|---|---|---|

| Total Income | US$ | XX | XX | XX | XX | XX |

| Total Expenditure | US$ | XX | XX | XX | XX | XX |

| Gross Profit | US$ | XX | XX | XX | XX | XX |

| Gross Margin | % | XX | XX | XX | XX | XX |

| Net Profit | US$ | XX | XX | XX | XX | XX |

| Net Margin | % | XX | XX | XX | XX | XX |

Report Coverage:

| Report Features | Details |

|---|---|

| Product Name | Broccoli and Cheese Bites |

| Report Coverage | Detailed Process Flow: Unit Operations Involved, Quality Assurance Criteria, Technical Tests, Mass Balance, and Raw Material Requirements Land, Location and Site Development: Selection Criteria and Significance, Location Analysis, Project Planning and Phasing of Development, Environmental Impact, Land Requirement and Costs Plant Layout: Importance and Essentials, Layout, Factors Influencing Layout Plant Machinery: Machinery Requirements, Machinery Costs, Machinery Suppliers (Provided on Request) Raw Materials: Raw Material Requirements, Raw Material Details and Procurement, Raw Material Costs, Raw Material Suppliers (Provided on Request) Packaging: Packaging Requirements, Packaging Material Details and Procurement, Packaging Costs, Packaging Material Suppliers (Provided on Request) Other Requirements and Costs: Transportation Requirements and Costs, Utility Requirements and Costs, Energy Requirements and Costs, Water Requirements and Costs, Human Resource Requirements and Costs Project Economics: Capital Costs, Techno-Economic Parameters, Income Projections, Expenditure Projections, Product Pricing and Margins, Taxation, Depreciation Financial Analysis: Liquidity Analysis, Profitability Analysis, Payback Period, Net Present Value, Internal Rate of Return, Profit and Loss Account, Uncertainty Analysis, Sensitivity Analysis, Economic Analysis Other Analysis Covered in The Report: Market Trends and Analysis, Market Segmentation, Market Breakup by Region, Price Trends, Competitive Landscape, Regulatory Landscape, Strategic Recommendations, Case Study of a Successful Venture |

| Currency | US$ (Data can also be provided in the local currency) |

| Customization Scope | The report can also be customized based on the requirement of the customer |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through email (We can also provide the editable version of the report in PPT/Word format on special request) |

Report Customization

While we have aimed to create an all-encompassing broccoli and cheese bites plant project report, we acknowledge that individual stakeholders may have unique demands. Thus, we offer customized report options that cater to your specific requirements. Our consultants are available to discuss your business requirements, and we can tailor the report's scope accordingly. Some of the common customizations that we are frequently requested to make by our clients include:

- The report can be customized based on the location (country/region) of your plant.

- The plant’s capacity can be customized based on your requirements.

- Plant machinery and costs can be customized based on your requirements.

- Any additions to the current scope can also be provided based on your requirements.

Why Buy IMARC Reports?

- The insights provided in our reports enable stakeholders to make informed business decisions by assessing the feasibility of a business venture.

- Our extensive network of consultants, raw material suppliers, machinery suppliers and subject matter experts spans over 100+ countries across North America, Europe, Asia Pacific, South America, Africa, and the Middle East.

- Our cost modeling team can assist you in understanding the most complex materials. With domain experts across numerous categories, we can assist you in determining how sensitive each component of the cost model is and how it can affect the final cost and prices.

- We keep a constant track of land costs, construction costs, utility costs, and labor costs across 100+ countries and update them regularly.

- Our client base consists of over 3000 organizations, including prominent corporations, governments, and institutions, who rely on us as their trusted business partners. Our clientele varies from small and start-up businesses to Fortune 500 companies.

- Our strong in-house team of engineers, statisticians, modeling experts, chartered accountants, architects, etc. has played a crucial role in constructing, expanding, and optimizing sustainable manufacturing plants worldwide.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Frequently Asked Questions

Capital requirements generally include land acquisition, construction, equipment procurement, installation, pre-operative expenses, and initial working capital. The total amount varies with capacity, technology, and location.

To start a broccoli and cheese bites manufacturing business, one needs to conduct a market feasibility study, secure required licenses, arrange funding, select suitable land, procure equipment, recruit skilled labor, and establish a supply chain and distribution network.

Broccoli and cheese bites manufacturing requires raw materials such as broccoli florets, shredded cheese (like cheddar and parmesan), eggs, and breadcrumbs. Other common ingredients are flour, garlic powder, onion, salt, and pepper. For frying, oil is used for deep-frying or spraying, while for baking, oil or cooking spray is used to prevent sticking.

A broccoli and cheese bites factory typically require vegetable washers, cutters, steam blanchers, cheese shredders, mixing machines, coating and breading lines, forming machines, deep fryers or ovens, blast freezers, weighing and packaging machines, metal detectors, conveyors, and cold storage units, along with quality control and sanitation equipment for hygienic production.

The main steps generally include:

-

Wash and cut fresh broccoli into pieces

-

Steam blanch broccoli to retain color and texture

-

Grate and prepare cheese for mixing

-

Mix broccoli, cheese, and binding ingredients

-

Form mixture into uniform bite-sized shapes

-

Coat with batter and breadcrumbs evenly

-

Fry or bake until golden and crisp

-

Cool and freeze

-

Pack, store, and distribute

Usually, the timeline can range from 12 to 24 months to start a broccoli and cheese bites manufacturing plant, depending on factors like site development, machinery installation, environmental clearances, safety measures, and trial runs.

Challenges may include high capital requirements, securing regulatory approvals, ensuring raw material supply, competition, skilled manpower availability, and managing operational risks.

Typical requirements include business registration, environmental clearances, factory licenses, fire safety certifications, and industry-specific permits. Local/state/national regulations may apply depending on the location.

The top broccoli and cheese bites manufacturers are:

-

McCain Foods

-

Kraft Heinz Company

-

Birds Eye

-

Freshezy Foods

-

Earth's Best

Profitability depends on several factors including market demand, manufacturing efficiency, pricing strategy, raw material cost management, and operational scale. Profit margins usually improve with capacity expansion and increased capacity utilization rates.

Cost components typically include:

-

Land and Infrastructure

-

Machinery and Equipment

-

Building and Civil Construction

-

Utilities and Installation

-

Working Capital

Break even in a broccoli and cheese bites manufacturing business typically range from 3 to 6 years, depending on scale, regulatory compliance costs, raw material pricing, and market demand. Efficient manufacturing and export opportunities can help accelerate returns.

Governments may offer incentives such as capital subsidies, tax exemptions, reduced utility tariffs, export benefits, or interest subsidies to promote manufacturing under various national or regional industrial policies.

Financing can be arranged through term loans, government-backed schemes, private equity, venture capital, equipment leasing, or strategic partnerships. Financial viability assessments help identify optimal funding routes.

Inquire Before Buying

Inquire Before Buying

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Request Customization

Request Customization