CapEx Calculator

The CapEx (Capital Expenditure) Calculator is a valuable tool that assists firms and entrepreneurs in estimating the total capital investment necessary to establish a manufacturing unit. This simple calculator breaks down all of the primary costs connected with establishing a manufacturing plant, helping users to better plan and spend their financial resources.

What is the importance of a CapEx Calculator?

The CapEx Calculator is designed to provide fast and precise estimates of the capital required to establish a manufacturing facility based on key user-defined parameters. It fulfills several essential functions:

- Initial Capital Requirement Assessment: It helps companies project the amount of investment required for infrastructure, machinery, equipment, and other initial costs.

- Financial Planning Support: By matching projected costs with available budgets, the calculator ensures the project stays within budgetary limits

- Informed Decision-Making: The CapEx Calculator provides an initial understanding of the estimated capital required to setup a plant, making it possible for stakeholders to assess the viability of a project, determine cost optimization areas, and make adjustments accordingly.

- Reduction of Financial Risk: It lessens the risk of unreliable capital projections, which can have negative consequences on project implementation and funding availability.It processes the following:

How CapEx Calculator Works?

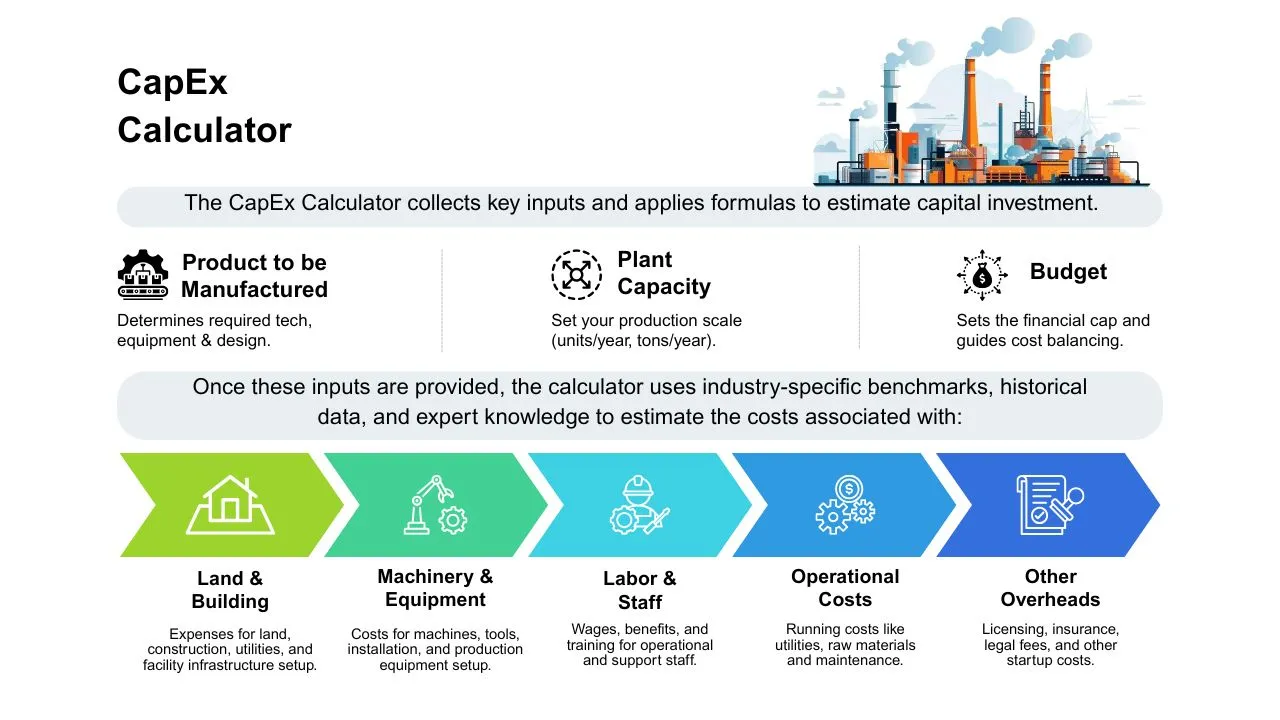

The CapEx Calculator works by gathering key inputs from the user that help us estimating the initial estimated capital investment.

- Product to be Manufactured: Defines the type of product to be produced in the facility.

- Plant Capacity: Determines the size and scale of the plant based on the expected production output.

- Budget: Provides an overall financial cap, helping the calculator adjust the cost estimates accordingly.

Once these inputs are provided, the calculator uses industry-specific benchmarks, historical data, and expert knowledge to estimate the costs associated with:

- Land and Building: Construction, site preparation, utilities setup.

- Machinery and Equipment: Cost of purchasing, installing, and commissioning production equipment.

- Labor and Staff: Estimation of workforce-related expenses.

- Operational Costs: Running costs like utilities, raw materials, and maintenance.

- Other Overheads: Including regulatory fees, licenses, and insurance.

The CAPEX Calculator provides a clear picture of the overall investment required to start production.

What is included in the CapEx Calculator?

The CapEx Calculator uses the following inputs:

Product to be Manufactured

This input specifies the sort of product you want to manufacture at your planned factory. It might include consumer items, chemicals, food products, electronics, and more. The product chosen will assist us in estimating the resources, machinery, and technology necessary for the plant setup, as various goods have unique production requirements.

Choose the product category from a drop-down menu that you intend to manufacture. The product type has an impact on the plant's design, equipment, operating procedures, and the amount of investment required in machinery and raw materials.

Plant Capacity

This input determines your plant's production capacity, which is commonly expressed as the number of items produced per year (e.g., units, tons, liters). Plant capacity defines the facility's size, the number and kind of machinery, and personnel needs, all of which influence CapEx. A higher capacity often raises expenses owing to increased infrastructure and equipment requirements.

Enter the expected production capacity in units per time (e.g., Tons per Year, Units per Year, etc.). For example, if you plan to produce 5000 Tons per Year, simply enter 5000 in the input field.

The plant capacity helps determine the scale of operations and, in turn, the size of the plant, the number of employees, machinery required, and the overall cost estimation for setting up the facility.

Budget

The budget refers to the total amount of money you are willing to invest in setting up the manufacturing plant. This includes all costs such as land, building, machinery, equipment, labor, working capital, and other overheads.

Enter your budget for the plant setup in monetary terms (e.g., US$ 5 Million, etc.). You can either input a rough estimate or a precise amount depending on your financial planning.

The budget input is critical because it helps in calculating whether the estimated Capital Expenditure (CapEx) required to establish the plant aligns with your available funds. It also influences the scale of equipment, plant design, and construction.

FAQ’s

The CapEx Calculator provides close estimates based on industry benchmarks, current pricing trends, and regional cost factors. While it gives a strong initial projection, a detailed feasibility study is recommended for final budgeting.

CapEx cost estimation typically includes land, building construction, machinery, installation, licensing, utilities setup, and working capital requirements.

The calculator can estimate CapEx for a wide range of industries, including pharmaceuticals, renewable energy, food and beverage, chemicals, consumer goods, and more. You simply choose/enter the product and relevant inputs.

Absolutely. Whether you're setting up a small bakery or a large chemical plant, the calculator adjusts for project size and scale.

Yes, location-based modifiers are applied to reflect regional pricing differences in labor, material, and logistics.

Yes, both new plant setups (greenfield) and expansion/upgrades (brownfield) can be estimated using relevant input fields.

The initial CapEx estimate is free. However, a full detailed report—covering machinery, installation, raw materials, and ROI projections—is shared upon inquiry and involve a fee depending on project scope.

Once your inquiry is submitted, our team reviews your inputs and sent the CapEx estimate directly to your email.

Our sales representative will reach out to you as soon as possible with the desired CapEx estimate.