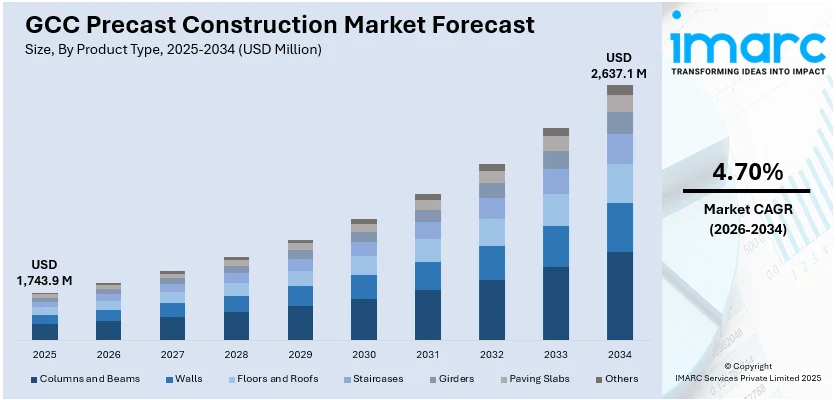

GCC Precast Construction Market Report by Product Type (Columns and Beams, Walls, Floors and Roofs, Staircases, Girders, Paving Slabs, and Others), Construction Type (Modular, Manufactured Homes), End User (Residential, Non-Residential), and Country 2026-2034

Market Overview:

GCC precast construction market size reached USD 1,743.9 Million in 2025. Looking forward, the market is expected to reach USD 2,637.1 Million by 2034, exhibiting a growth rate (CAGR) of 4.70% during 2026-2034. The escalating demand for sustainable, cost-effective, and time-efficient approach that provide numerous advantages for construction projects of diverse scales and complexities is primarily driving the regional market.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2025 |

|

Forecast Years

|

2026-2034

|

|

Historical Years

|

2020-2025

|

| Market Size in 2025 | USD 1,743.9 Million |

| Market Forecast in 2034 | USD 2,637.1 Million |

| Market Growth Rate (2026-2034) | 4.70% |

Precast construction is a modern and efficient building method that involves manufacturing structural components off-site and then transporting and assembling them at the construction site. The process begins with the creation of precast concrete elements in a controlled factory environment. These components, which can include walls, columns, beams, and slabs, are cast to precise specifications, ensuring high quality and consistency. Once the precast elements are ready, they are transported to the construction site, where they are assembled and connected using various techniques like welding or bolting. One of the key advantages of precast construction is its ability to streamline the building process, significantly reducing construction time. The controlled factory environment ensures optimal curing conditions, resulting in durable and resilient concrete elements. Additionally, precast construction minimizes on-site labor requirements, leading to cost savings and increased efficiency. The versatility of precast construction allows for a wide range of architectural designs and applications. Precast elements can be customized to meet specific project requirements, enabling creative and complex structures. This method is widely used in various construction sectors, including residential, commercial, industrial, infrastructure projects, etc.

To get more information on this market Request Sample

GCC Precast Construction Market Trends:

Urban Development and Population Growth

GCC precast construction market is experiencing strong momentum as rapid population growth and urban developments are transforming city skylines throughout the region. Governments, private developers, and builders are turning to precast construction increasingly to capture the growing demand for residential, commercial, and infrastructure projects. Cities like Riyadh, Dubai, Doha, and Jeddah are always in the process of expanding, requiring quicker and more efficient methods of construction to support increasing populations. This expansion of cities is exerting pressure on conventional construction practices, leading the stakeholders to move towards precast solutions that provide time and cost savings. Moreover, megaprojects such as Saudi Vision 2030 and the Dubai 2040 Urban Master Plan are driving massive urban development, further fueling the need for modular and expandable construction practices. With reduced construction duration, lower labor expenses, and consistent quality, precast elements are becoming central to urban planning strategies all over the GCC. Governing agencies are also expanding commercial projects. For example, in 2024, Dubai invested $2.7 billion (AED10 billion) for the expansion of Dubai Exhibition Centre (DEC) at Expo City Dubai. The project was initiated by Dubai ruler Sheikh Mohammed bin Rashid Al Maktoum and was considered to become the largest exhibition center in the Middle East.

Government Investments in Infrastructure Projects

Governments within the GCC are regularly making investments in large-scale infrastructure projects that are integral to national transformation plans and economic diversification initiatives, driving the demand for precast construction. Saudi Arabia, the UAE, and Qatar are devoting significant budgets to roads, airports, metro lines, bridges, and public utilities, all of which are facilitated through the efficiency of precast technology. The use of precast elements in these mega infrastructure projects is gaining prominence as they can help achieve tight construction schedules and maintain high quality and safety standards. Mega-projects such as NEOM in Saudi Arabia, the Etihad Rail project in the UAE, and FIFA World Cup legacy infrastructure in Qatar are constantly generating a need for prefabricated solutions. By streamlining project delivery time and reducing on-site construction complexities, precast systems are supporting the region's emphasis on developing sustainable, future-proof infrastructure, driving long-term market expansion. In 2025, the United Arab Emirates has announced a fresh federal strategic planning cycle, signaling a transition towards data-oriented governance and the incorporation of artificial intelligence (AI). It creates strategic opportunities for international investors in areas such as technology, infrastructure, finance, and cybersecurity. The planning cycle emphasizes smart city growth, FinTech advancements, predictive analytics, and interdisciplinary AI uses in healthcare and logistics.

Growing Emphasis on Construction Efficiency and Time Reduction

The GCC precast construction industry is expanding significantly as contractors and developers are focusing more on enhancing construction efficiency and shortening project durations. Conventional construction techniques are becoming less feasible under conditions of aggressive development timelines and labor cost pressures. Precast construction is providing a realistic alternative by facilitating off-site fabrication, allowing for concurrent on-site preparation and structural component manufacture. This process is reducing project durations substantially and decreasing on-site labor demands. With more complex construction projects and tighter deadlines, especially for high-profile projects, coming up, the capability to optimize processes without sacrificing quality is becoming a competitive edge. The need for just-in-time delivery, modular design capacity, and faster installation processes is increasing on a daily basis. This drive for efficiency is encouraging construction companies throughout the GCC to incorporate precast solutions into their mainstream strategies, thus strengthening market growth. IMARC Group predicts that the GCC construction market is projected to reach USD 226.2 Billion by 2033.

GCC Precast Construction Market Growth Drivers:

Increased Need for Green and Sustainable Building Solutions

Environmental sustainability is emerging as a prime focus within the GCC construction sector, and the market for precast construction is adapting by providing environment friendly solutions that meet green building criteria. Developers and governments are increasingly turning to green construction methods to serve global environmental obligations and local regulatory requirements. Precast components are at the vanguard of this trend, since they are made in controlled environments, involving less waste of materials, lower levels of carbon emissions, and greater energy efficiency. The reusability and recyclability of precast material are also assisting construction projects in achieving LEED and other green certification. With increased awareness about climate change and the conservation of resources, the GCC construction industry is increasingly incorporating environmental objectives into project planning. The objectives are being achieved by precast systems that guarantee the sustainable procurement of materials, minimize water consumption, and enable low-impact site practices.

Labor Shortages and Increased Construction Costs

Labor shortages and rising construction costs are constantly affecting the move towards precast construction within the GCC region. Highly dependent on expatriate labor, the construction sector is increasingly being hit by fluctuations in the labor market, tighter immigration controls, and rising wage claims. These pressures are compelling developers and contractors to find different forms of construction that lower dependence on manpower. Precast technology is already overcoming this issue by mechanizing large parts of the construction process and enabling prefabrication in controlled factory environments. Consequently, fewer personnel have to be on the job site, and construction times are considerably shorter. Additionally, increased costs of raw materials and transportation are inspiring firms to turn to more economical construction methods. By reducing material wastage, improving productivity, and reducing labor intensity, precast systems are proving to be a cost-effective option. The industry is responding more to these economic imperatives by increasing the application of precast elements in various construction sectors.

Technological Innovation in Precast Production

Innovations in manufacturing technology and digital building solutions are further adding capabilities and attractiveness to precast construction in the GCC. The integration of building information modeling (BIM), automated casting systems, and robotics is enabling greater precision, customization, and efficiency in precast production. Manufacturers are increasingly leveraging these technologies to produce high-quality components that meet specific project requirements and architectural designs. This technological evolution is allowing for faster production cycles, better quality control, and seamless coordination between design and construction teams. Besides, the use of smart logistics, real-time monitoring systems, and digital project management software is enhancing supply chain efficiency and minimizing delays in projects. As the construction industry adopts digitalization, precast plants are moving along the same lines to provide innovative solutions that address intricate engineering requirements. The constant innovation in precast technology is setting it as a future-proofing construction practice, compelling its mass adoption across the GCC market.

GCC Precast Construction Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the regional and country level for 2026-2034. Our report has categorized the market based on product type, construction type, and end user.

Product Type Insights:

- Columns and Beams

- Walls

- Floors and Roofs

- Staircases

- Girders

- Paving Slabs

- Others

The report has provided a detailed breakup and analysis of the market based on the product type. This includes columns and beams, walls, floors and roofs, staircases, girders, paving slabs, and others.

Construction Type Insights:

- Modular

- Manufactured Homes

A detailed breakup and analysis of the market based on the construction type have also been provided in the report. This includes modular and manufactured homes.

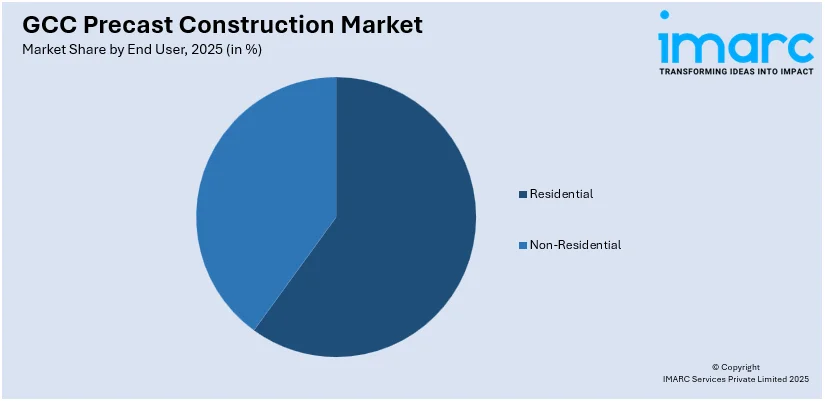

End User Insights:

Access the comprehensive market breakdown Request Sample

- Residential

- Non-Residential

The report has provided a detailed breakup and analysis of the market based on the end user. This includes residential and non-residential.

Country Insights:

- Saudi Arabia

- United Arab Emirates

- Qatar

- Kuwait

- Oman

- Bahrain

The report has also provided a comprehensive analysis of all the major regional markets, which include Saudi Arabia, United Arab Emirates, Qatar, Kuwait, Oman, and Bahrain.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape in the market. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

GCC Precast Construction Market News:

- March 2025: Jafza is reinforcing its status with a strategic AED 90 million investment in the second phase of its state-of-the-art Logistics Park. The expansion introduces 360,000 square feet of Grade-A facilities, supporting the UAE's goal to boost its logistics sector to AED 200 billion annually within seven years and reinforcing Dubai’s position in global trade.

- February 2025: MIG Holding and National Industries Park (NIP), a DP World subsidiary, have launched ‘Safetech’, the biggest precast concrete factory in the Middle East, covering 2.2 million square feet. The state-of-the-art facility, featuring a 750,000-square-foot manufacturing space and an 800,000-square-foot storage yard, boasts an annual production capacity exceeding 700,000 cubic metres.

- October 2024: Saudi Arabia’s forthcoming linear city initiative THE LINE will gain from a new ready-mix concrete plant worth SR700 million ($186.7 million). NEOM has collaborated with Asas Al-Mohileb to create and manage this facility, which will concentrate on manufacturing sustainable concrete mainly for building the smart city, aimed at housing 9 million residents in a condensed 34 sq. km area.

GCC Precast Construction Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2025 |

| Historical Period | 2020-2025 |

| Forecast Period | 2026-2034 |

| Units | Million USD |

| Scope of the Report | Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Product Types Covered | Columns and Beams, Walls, Floors and Roofs, Staircases, Girders, Paving Slabs, Others |

| Construction Types Covered | Modular, Manufactured Homes |

| End Users Covered | Residential, Non-Residential |

| Countries Covered | Saudi Arabia, United Arab Emirates, Qatar, Kuwait, Oman, Bahrain |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the GCC precast construction Market from 2020-2034.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the GCC precast construction Market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the GCC precast construction industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Key Questions Answered in This Report

The GCC precast construction market was valued at USD 1,743.9 Million in 2025.

The GCC precast construction market is projected to exhibit a CAGR of 4.70% during 2026-2034, reaching a value of USD 2,637.1 Million by 2034.

The GCC precast construction market is driven by rapid urbanization, infrastructure development, and demand for cost-effective, time-efficient building methods. Government-backed megaprojects, labor shortages, and a focus on sustainability also increase construction activities. Precast solutions support faster project delivery, quality control, and reduced site disruption further align with regional construction modernization goals.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)