Germany 3D Printing Market Size, Share, Trends and Forecast by Technology, Process, Material, Offering, Application, End-User, and Region, 2025-2033

Germany 3D Printing Market Overview:

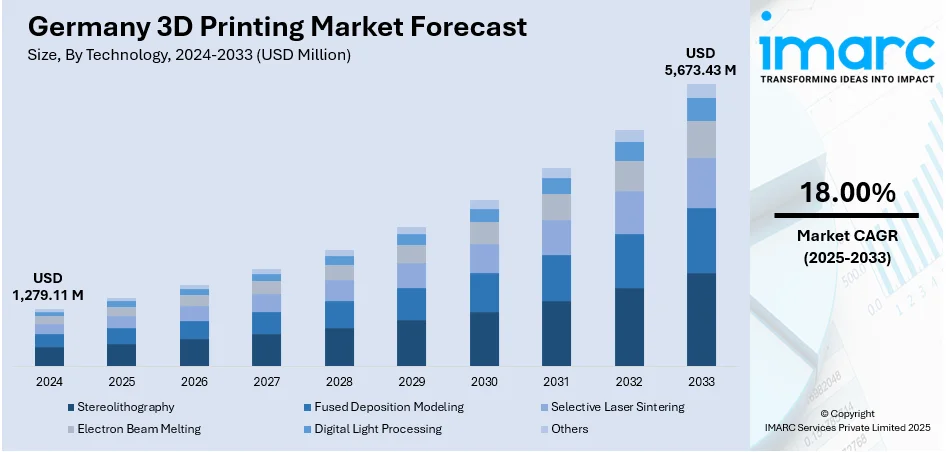

The Germany 3D printing market size reached USD 1,279.11 Million in 2024. Looking forward, IMARC Group expects the market to reach USD 5,673.43 Million by 2033, exhibiting a growth rate (CAGR) of 18.00% during 2025-2033. The market is primarily driven by the growing adoption in the automotive and aerospace sectors for producing lightweight and complex parts, increasing applications in healthcare for personalized medical devices, and the rising usage of metal 3D printing in industrial manufacturing for enhanced strength and precision-engineered components.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2024 |

|

Forecast Years

|

2025-2033

|

|

Historical Years

|

2019-2024

|

| Market Size in 2024 | USD 1,279.11 Million |

| Market Forecast in 2033 | USD 5,673.43 Million |

| Market Growth Rate 2025-2033 | 18.00% |

Germany 3D Printing Market Trends:

Increasing Adoption in the Automotive and Aerospace Sectors

The 3D printing market in Germany is witnessing significant adoption across the automotive and aerospace sectors, driven by the demand for lightweight, complex components. In line with this, the rising industrial use of 3D printing has enabled manufacturers to create hard-to-achieve complex geometries in parts. The attractiveness of material reduction and production time reduction appeals to these industrial sectors because sustainability and efficiency stand as their main priorities. For instance, Volkswagen Group expanded its 3D printing capabilities by adding a second MetalFAB system, enhancing efficiency and precision in automotive manufacturing for lightweight and complex components. This shift demonstrates how additive manufacturing becomes essential for businesses to optimize production capabilities while achieving better design adaptability. Through 3D printing, manufacturers gain a mechanism to create prototypes easily which helps them modify designs until they reach optimal results before full-scale production. As a result, the industrialized economy and emerging manufacturing technologies and investments enable low-cost high-accuracy production in the automotive and aerospace industries, which is Germany 3D printing market outlook.

Expansion in Medical and Healthcare Applications

The medical and healthcare sectors in Germany are increasingly integrating 3D printing technology for customized solutions in areas such as prosthetics, implants, and surgical tools. For example, in 2024, 3D Systems received FDA 510(k) clearance for their VSP® PEEK Cranial Implants, marking the first FDA-cleared, additively manufactured PEEK implant for cranioplasty procedures. This trend is driven by the technology’s ability to create patient-specific medical devices, improving precision and better outcomes in treatments. Moreover, the advancement of tissue and organ printing through bioprinting requires 3D printing methods as its fundamental basis. German healthcare providers and research institutions spend resources together to advance medical innovation through this technology for the fast production of customized medical devices. Furthermore, the rising healthcare demand for personalized treatment combined with its advanced medical infrastructure is boosting the Germany 3D printing market share.

Rising Use of Metal 3D Printing in Industrial Manufacturing

The use of metal 3D printing for industrial manufacturing is a trend that is enhancing the Germany 3D printing market outlook. Metal additive manufacturing is emerging as a vital instrument as businesses strive to create components that are more robust, intricate, and high-performing. Metal 3D printing is being used by industries such as aerospace, automotive, and defense to produce parts that are lighter and more robust. The capacity to create products with better mechanical qualities using additive manufacturing is revolutionizing production processes. Metals including titanium, stainless steel, and aluminum can be used in this way. For instance, Caracol AM unveiled its first metal 3D printer, the Vipra AM, at Formnext 2024 in Frankfurt. The directed energy deposition (DED) system offers two configurations, Vipra XQ, targeting high-strength materials like titanium for aerospace applications, and Vipra XP, optimized for aluminum and nickel alloys, emphasizing productivity. To fulfill the demand for precision-engineered parts, German firms are investing more in metal 3D printing, which is encouraging innovation and boosting the nation's industrial capabilities in sophisticated manufacturing technologies.

Germany 3D Printing Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the region level for 2025-2033. Our report has categorized the market based on technology, process, material, offering, application, and end-user.

Technology Insights:

- Stereolithography

- Fused Deposition Modeling

- Selective Laser Sintering

- Electron Beam Melting

- Digital Light Processing

- Others

The report has provided a detailed breakup and analysis of the market based on the technology. This includes stereolithography, fused deposition modeling, selective laser sintering, electron beam melting, digital light processing, and others.

Process Insights:

- Binder Jetting

- Directed Energy Deposition

- Material Extrusion

- Material Jetting

- Powder Bed Fusion

- Sheet Lamination

- Vat Photopolymerization

A detailed breakup and analysis of the market based on the process have also been provided in the report. This includes binder jetting, directed energy deposition, material extrusion, material jetting, powder bed fusion, sheet lamination, and vat photopolymerization.

Material Insights:

- Photopolymers

- Plastics

- Metals and Ceramics

- Others

The report has provided a detailed breakup and analysis of the market based on the material. This includes photopolymers, plastics, metals and ceramides, and others.

Offering Insights:

- Printer

- Material

- Software

- Service

A detailed breakup and analysis of the market based on the offering have also been provided in the report. This includes printer, material, software, and service.

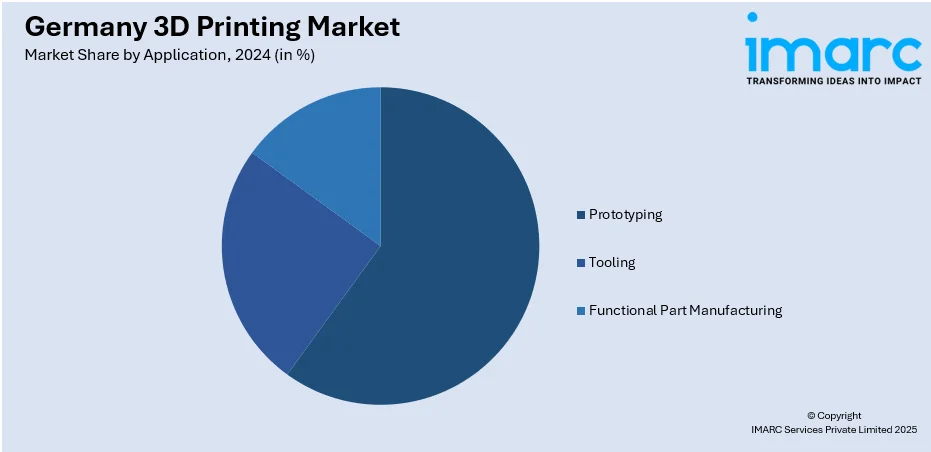

Application Insights:

- Prototyping

- Tooling

- Functional Part Manufacturing

The report has provided a detailed breakup and analysis of the market based on the application. This includes prototyping, tooling, and functional part manufacturing.

End-User Insights:

- Consumer Products

- Machinery

- Healthcare

- Aerospace

- Automobile

- Others

A detailed breakup and analysis of the market based on the end-user have also been provided in the report. This includes consumer products, machinery, healthcare, aerospace, automobile, and others.

Regional Insights:

- Western Germany

- Southern Germany

- Eastern Germany

- Northern Germany

The report has also provided a comprehensive analysis of all the major regional markets, which include Western Germany, Southern Germany, Eastern Germany, and Northern Germany.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

Germany 3D Printing Market News:

- In November 2023, Eisenbacher Dentalwaren and Eplus3D completed a joint project demonstrating that Eisenbacher's KeraS metal powder can be processed on Eplus3D's metal 3D printers. This advancement enables dental laboratories to produce high-quality, precise dental frameworks, meeting DIN EN ISO 22674 standards for type 5 alloys.

- In October 2023, AMCM, The German manufacturing company AMCM unveiled its new metal Laser Beam Powder Bed Fusion (PBF-LB) 3D printer called the AMCM M 8K. With 8 1kW lasers and a vast build area, this printer was engineered to create combustion chambers for Prometheus rocket engine production at ArianeGroup for the Ariane 6 program of the European Space Agency. The integration between EOS's SmartFusion and EOSTATE Exposure OT systems enables improved quality assessment and process monitoring during the manufacturing of large parts.

Germany 3D Printing Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2024 |

| Historical Period | 2019-2024 |

| Forecast Period | 2025-2033 |

| Units | Million USD |

| Scope of the Report |

Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Technologies Covered | Stereolithography, Fused Deposition Modeling, Selective Laser Sintering, Electron Beam Melting, Digital Light Processing, Others |

| Processes Covered | Binder Jetting, Directed Energy Deposition, Material Extrusion, Material Jetting, Powder Bed Fusion, Sheet Lamination, Vat Photopolymerization |

| Materials Covered | Photopolymers, Plastics, Metals and Ceramides, Others |

| Offerings Covered | Printer, Material, Software, Service |

| Applications Covered | Prototyping, Tooling, Functional Part Manufacturing |

| End-Users Covered | Consumer Products, Machinery, Healthcare, Aerospace, Automobile, Others |

| Regions Covered | Western Germany, Southern Germany, Eastern Germany, Northern Germany |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the Germany 3D printing market performed so far and how will it perform in the coming years?

- What is the breakup of the Germany 3D printing market on the basis of technology?

- What is the breakup of the Germany 3D printing market on the basis of process?

- What is the breakup of the Germany 3D printing market on the basis of material?

- What is the breakup of the Germany 3D printing market on the basis of offering?

- What is the breakup of the Germany 3D printing market on the basis of application?

- What is the breakup of the Germany 3D printing market on the basis of end-user?

- What is the breakup of the Germany 3D printing market on the basis of region?

- What are the various stages in the value chain of the Germany 3D printing market?

- What are the key driving factors and challenges in the Germany 3D printing?

- What is the structure of the Germany 3D printing market and who are the key players?

- What is the degree of competition in the Germany 3D printing market?

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the Germany 3D printing market from 2019-2033

- The research report provides the latest information on the market drivers, challenges, and opportunities in the Germany 3D printing market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the Germany 3D printing industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)