High Temperature Sealant Market Size, Share, Trends and Forecast by Chemistry, Application, and Region, 2025-2033

High Temperature Sealant Market Size and Share:

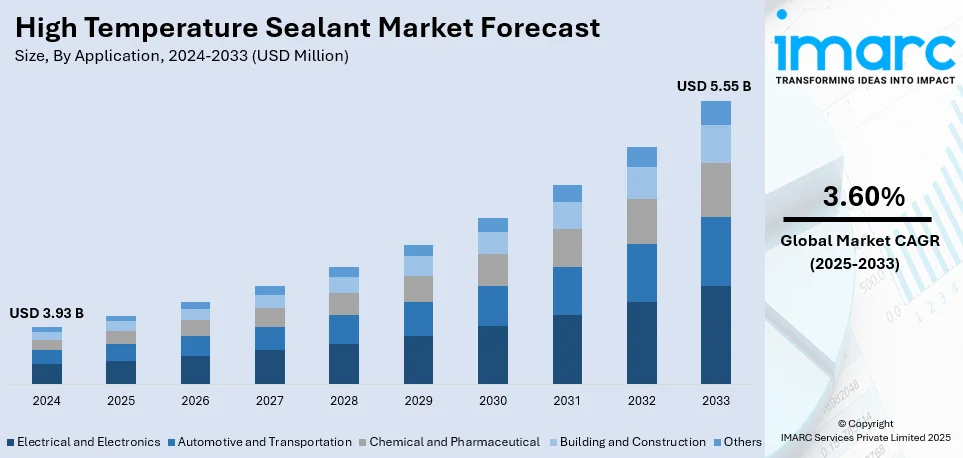

The global high temperature sealant market size was valued at USD 3.93 Billion in 2024. Looking forward, IMARC Group estimates the market to reach USD 5.55 Billion by 2033, exhibiting a CAGR of 3.60% from 2025-2033. Asia Pacific currently dominates the market owing to the growing utilization of renewable energy sources to mitigate the impact of climate change, the advent of electric vehicles and high-performance cars requiring reliable and technological advancements are some of the major factors propelling the market. At present, Asia Pacific dominates the market, fueled by rapid infrastructure development and expansion in the construction sector.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2024 |

|

Forecast Years

|

2025-2033

|

|

Historical Years

|

2019-2024

|

| Market Size in 2024 | USD 3.93 Billion |

| Market Forecast in 2033 | USD 5.55 Billion |

| Market Growth Rate (2025-2033) | 3.60% |

One of the major drivers in the high temperature sealant market outlook is the increasing demand from the automotive and aerospace industries. High-temperature sealants are critical for these sectors as they provide critical performance in extreme heat conditions. In the automotive industry, they are used to seal engine components and exhaust systems, ensuring durability and efficiency. Similar application fields are also the high-temperature sealants used to prevent detrimental environments in aerospace applications imposed on engines and structural parts. With the development of advanced vehicles and aircraft, these industries are developing constantly, thus calling for higher performance from the sealants used in such applications.

In the U.S., the high temperature sealant market is driven by robust demand from industries such as automotive, aerospace, and manufacturing with 80.30% market share. The automotive sector requires sealants for engine components, exhaust systems, and heat shields to withstand extreme temperatures and ensure durability. In aerospace, high-temperature sealants are critical for engines, turbines, and other components exposed to intense heat. Additionally, the U.S. industrial manufacturing sector utilizes these sealants in machinery and equipment that operate under high thermal conditions. As the U.S. continues to focus on technological advancements and manufacturing growth, the demand for high-temperature sealants is expected to rise steadily.

High Temperature Sealant Market Trends:

Rapid Industrialization and Urbanization

One of the major market drivers for the high temperature sealant industry is the fast pace of industrialization and urbanization going on in various parts of the world. It is estimated by the United Nations (UN) that 68% of the world's population will live in cities by 2050. With globalization increasing, emerging markets like India, China, and Brazil are going through rapid industrialization. This growth creates an increased demand for sealants, especially those capable of surviving high temperatures, as a result of their use in various industries, such as automotive, construction, and aerospace. As an example in the construction sector, these sealants are critical in providing durability and efficiency in high-heat equipment and infrastructure. Further, urbanization leads to a higher demand for residential and commercial buildings, increasing the need for high-temperature sealants in construction.

Stringent Regulations and Standards

The widespread implementation of stricter regulations and standards concerning safety and emissions widely developed by the governing authorities is driving the market. Besides, governments around the world are implementing regulations that require the application of high-performance sealants to prevent leakage and equipment failure in the power generation and oil & gas industries, among others. This, therefore increases the demand for high-performance sealants with extreme temperature resistance. The policies regarding greenhouse gas (GHG) emissions are forcing companies to invest in the advanced sealants to improve their equipment's efficiency and reduce carbon footprint. The International Energy Agency reports that the global energy-related CO₂ emissions increased by 1.1% in 2023, which rose by 410 million tons (Mt) to a record high of 37.4 billion tons (Gt). This is also contributing to the growth of the market.

Technological Developments

Another driver is the continuous advancement in technology within the sealant industry. As there are improvements, high-temperature sealants become more efficient, reliable, and adaptive to various conditions, hence broadening their applications. For instance, it is applied in electronics where the resistance to heat is very crucial in sustaining the life span and performance of components. According to reports, the consumer electronics industry expanded by 4.1% in 2023. Innovations in material science, such as the development of silicone-based sealants that can resist higher temperatures, have also augmented the high temperature sealant market demand. Some of the important focus areas that entail R&D are being focused on more eco-friendly sealants. This is a much needed and relevant factor in today's sustainability-driven market. These are high-temperature sealant market growth-shaping factors.

High Temperature Sealant Industry Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the global high temperature sealant market, along with forecast at the global, regional, and country levels from 2025-2033. The market has been categorized based on chemistry and application.

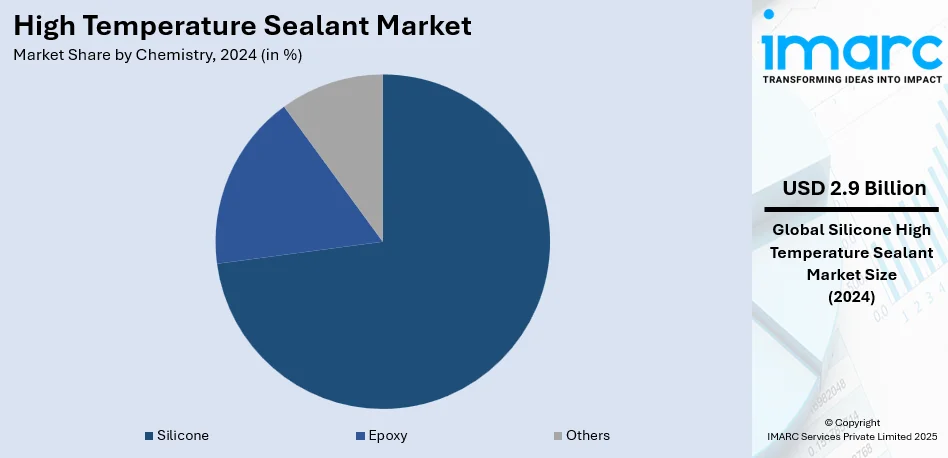

Analysis by Chemistry:

- Silicone

- Epoxy

- Others

The high-temperature sealant market is led by silicones, accounting for 72.6% of the overall market. Silicones are very thermally stable and versatile and can withstand extreme temperatures ranging from -55°C to 300°C, which makes them suitable for application in automotive, aerospace, and manufacturing sectors that require high-performance materials. Flexibility, resistance to environmental factors, and durability under heat stress make silicone sealants the preferred sealant for sealing applications in engines, turbines, exhaust systems, and heat shields. Moreover, its ability to sustain properties in adverse conditions like UV rays, moisture, and chemicals further adds to its market share. Such widespread applicability and reliability continues to fuel the growth of silicone-based sealants.

Analysis by Application:

- Electrical and Electronics

- Automotive and Transportation

- Chemical and Pharmaceutical

- Building and Construction

- Others

According to the high temperature sealant market forecast, the electrical and electronics sector significantly drives the demand due to the increasing need for components that can operate under high thermal stress. As electronic devices and electrical equipment become more powerful and compact, they generate higher amounts of heat, making reliable sealing materials crucial to ensure the longevity and safety of these devices. High-temperature sealants, especially silicone-based products, are used to protect critical components such as circuit boards, transformers, connectors, and cables. These sealants prevent heat-related damage, improve insulation, and enhance overall performance. With the rapid expansion of industries such as consumer electronics, electric vehicles, and renewable energy, demand for high-temperature sealants in the electrical and electronics sectors is steadily increasing.

Regional Analysis:

- North America

- United States

- Canada

- Europe

- Germany

- France

- United Kingdom

- Italy

- Spain

- Others

- Asia Pacific

- China

- Japan

- India

- South Korea

- Australia

- Indonesia

- Others

- Latin America

- Brazil

- Mexico

- Others

- Middle East and Africa

Asia Pacific holds the leading position in the high-temperature sealant market due to rapid industrialization, significant manufacturing growth, and an expanding automotive and aerospace sector. The region’s robust automotive production, especially in countries like China, Japan, and India, drives the demand for high-performance sealants in engine components, exhaust systems, and heat shields. Additionally, the growth of the electronics industry in countries like South Korea and China fuels the need for heat-resistant sealants in various electronic devices and components. Asia Pacific also benefits from a large manufacturing base, with industries such as chemicals, machinery, and renewable energy, all requiring high-temperature sealants for optimal performance. Favorable government policies and ongoing infrastructure projects further support the market’s expansion in the region.

Key Regional Takeaways:

North America High Temperature Sealant Market Analysis

Major demand for the product comes from the automotive, aerospace, and industrial sectors in North America. Automotive industries in the U.S. require high-temperature sealants for engine components, exhaust systems, and heat shields to withstand extreme conditions. Similarly, aerospace industries use sealants for their engines, turbines, and other high-heat components, demanding high durability and reliability. Industrial applications, particularly in manufacturing plants, machinery, and power generation, also contribute to the market's growth, as these industries require sealants to handle elevated temperatures in equipment like boilers, pumps, and reactors. The increasing focus on energy efficiency and environmental sustainability in North America is driving the demand for advanced sealant materials. Moreover, rapid technological advancements and electric vehicle technology development have inspired high-temperature sealants in this market with emerging automotive innovations. The existence of key players along with significant R&D strengths is also augmenting the dominance of this market in the region.

United States High Temperature Sealant Market Analysis

The United States high temperature sealant market is largely driven by growing demand across industries, such as aerospace, automotive, manufacturing, and electronics, where high performance and durability are paramount. As technological innovations and industrial advancements progress, the demand for advanced materials capable of withstanding extreme temperatures has grown substantially. The automotive sector is also a key driver, with an increasing need for sealants that can perform under high heat conditions in engines and exhaust systems. The thriving automotive industry in the region is bolstering the market growth. According to reports, 15,608,386 vehicle units were sold out in 2023 in United States. These sealants are used to prevent leaks, reduce vibrations, and provide thermal insulation in areas exposed to extreme temperatures. For example, high-temperature sealants are applied to exhaust systems, gaskets, turbochargers, and engine blocks to ensure reliable sealing and performance under the heat generated by internal combustion engines. In line with this, the rise in energy production activities, especially in oil and gas extraction, requires sealants that maintain integrity in high-temperature environments. Furthermore, the growing trend of replacing traditional materials with more advanced, high-performance sealants to improve the longevity and efficiency of machinery and equipment continues to support market growth. Apart from this, the increasing investments in industrial automation and infrastructure also present opportunities for market expansion.

Asia Pacific High Temperature Sealant Market Analysis

The high-temperature sealant market in the Asia Pacific region is fueled by rapid industrialization and urbanization, especially in countries such as China, India, Japan, and South Korea. As per the CIA, the urban population in China was 64.6% of total population in 2023. These nations have strong manufacturing sectors, including automotive, aerospace, and electronics, all of which rely heavily on high-performance sealants that can withstand extreme thermal conditions. China's status as the world's largest automotive producer and exporter has significantly increased the demand for high-temperature sealants in the automotive sector. The fast growth in energy production, especially in power plants and oil and gas industries, also demands heat-resistant materials for machinery and equipment. Additionally, the rise in infrastructure development, including construction, is increasing the need for high-temperature sealants in heating, ventilation, and air conditioning (HVAC) systems. These sealants are designed to endure the temperature extremes in industrial and residential construction, particularly in areas exposed to heat like chimneys, ducts, and stoves. They also help seal joints and gaps around windows, doors, and other structural components to improve energy efficiency and prevent heat loss. As industries in the region push for greater efficiency and product longevity, the adoption of advanced sealing materials that provide superior heat resistance becomes more prominent, contributing significantly to the market's expansion.

Europe High Temperature Sealant Market Analysis

The high temperature sealant market in Europe is influenced by stringent regulations and the increasing need for energy efficiency and sustainability across various industries. The push for electric vehicles (EVs) in Europe is creating a new demand for high-temperature sealants in battery systems, where thermal management is critical. According to reports, new electric car registrations in Europe topped 3.2 million in 2023. This was an increase of around 20% compared to the number registered in 2022. In addition, Europe serves as a hub for industrial manufacturing. There is a need for reliable sealants installed in equipment like turbines, boilers, and machinery that work under high-temperature conditions. The market sees opportunities as environmental pressure and concerns about the type of materials to be used increase. High-temperature sealants that facilitate these efforts are becoming more popular as the energy and automotive sectors actively move toward more environmentally friendly materials. Accordingly, high-temperature sealants are essential for the safe and effective operation of machinery such as heat exchangers, reactors, and pipelines that function under high pressure and heat in the chemical and pharmaceutical industries. In addition, the market is expanding as a result of the European region's growing emphasis on research and development, particularly on high-performance material innovation.

Latin America High Temperature Sealant Market Analysis

The market is on the expansion train due to energy, automotive, and industrial manufacturing sectors. When countries like Brazil and Mexico keep increasing their output of automobiles, there is ever-increasing need for high performance sealants resistant to extremely high temperatures in engines and exhaust. Due to this, expanding energy sectors--power generation mainly and oil and gas exploration areas--require ever greater quantities of reliable high temperature materials for service in turbines, reactors, pipelines, etc, and the use of high-temperature sealants is becoming a growing necessity of the pharmaceutical sector for maintaining the sterility levels in areas where it is provided and to enclose and cover processing equipment against environmental exposure and other harmful things. According to a report released by the Brazilian Drug Market Regulation System (CMED), the pharmaceutical market in the nation peaked in terms of turnover at about USD 28.49. Latin America is also moving gradually toward more efficient and durable materials in manufacturing, which adds to the greater demand for special sealants.

Middle East and Africa High Temperature Sealant Market Analysis

As part of its increased focus on constructing oil production facility expansions, increased industrial activities associated with power generation and heavy machinery, high-temperature sealant demand is pushed. Construction, in the Middle East, continues to expand very rapidly and provides a large portion of the required sealing solutions at high-heat environments. The Middle East and North Africa (MENA) region has demonstrated strong growth, with project awards totaling an impressive USD 101 billion in the first half of the year, according to reports. Additionally, ongoing investments in infrastructure and the growing importance of maintaining operational efficiency in extreme conditions further support market growth. Additionally, high-temperature sealants play a crucial role in the electrical and electronics industry by safeguarding components from heat, moisture, and other environmental factors.

Competitive Landscape:

Competition in the high temperature sealant market is diverse, comprising of both established firms as well as newcomers. Firms emphasize innovation and product development to sustain their position in the market. Most leading firms invest in the research and development by developing new formulations, ensuring improvement in their performance under extreme conditions. These firms also focus on building robust distribution channels and strategic collaborations to expand their market footprint. Smaller companies are finding niches in niche products tailored to specific industries, such as automotive or aerospace. Competition is further touched by pricing strategies due to manufacturers wanting a proper balance between performance and cost efficiency. Overall, the market is dynamic, with consistent technological progression continuing to evolve the competitive environment.

The report provides a comprehensive analysis of the competitive landscape in the high temperature sealant market with detailed profiles of all major companies, including:

- 3M Company

- American Sealants Inc.

- Arkema S.A.

- Dow Inc.

- H.B. Fuller Company

- Henkel AG & Co. KGaA

- Illinois Tool Works Inc.

- Mapei S.p.A.

- PPG Industries Inc.

- Sika AG

- Soudal N.V.

- Wacker Chemie AG

Latest News and Developments:

- September 2024: L&L Products announced the launch of its proprietary InsituCore™ foaming materials for lightweight composite manufacturing and its innovative PHASTER™ line of adhesives, sealants, reinforcements, and repair materials.

- May 2024: Weicon, a manufacturer of specialized chemical products, introduced Weicon Flex 310 M HT 220+, an adhesive and sealant designed for high-temperature applications.

- March 2024: WACKER announced the construction of a new production facility for silicone sealants at its Nünchritz site in Germany, marking a significant expansion of its sealants business. A total of around USD 21.4 Million has been budgeted for the expansion.

- January 2024: Freudenberg Sealing Technologies introduced a new thermoplastic material capable of withstanding extreme temperatures of up to 1,200°C without melting. This development is likely to contribute significantly to enhanced fire protection for electric vehicle drives. Quantix ULTRA from Freudenberg Sealing Technologies stands up against extreme temperatures. The material does not melt and ignite.

High Temperature Sealant Market Report Scope:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2024 |

| Historical Period | 2019-2024 |

| Forecast Period | 2025-2033 |

| Units | Billion USD |

| Scope of the Report |

Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Chemistries Covered | Silicone, Epoxy, Others |

| Applications Covered | Electrical and Electronics, Automotive and Transportation, Chemical and Pharmaceutical, Building and Construction, Others |

| Regions Covered | Asia Pacific, Europe, North America, Latin America, Middle East and Africa |

| Countries Covered | United States, Canada, Germany, France, United Kingdom, Italy, Spain, Russia, China, Japan, India, South Korea, Australia, Indonesia, Brazil, Mexico |

| Companies Covered | 3M Company, American Sealants Inc., Arkema S.A., Dow Inc., H.B. Fuller Company, Henkel AG & Co. KGaA, Illinois Tool Works Inc., Mapei S.p.A., PPG Industries Inc., Sika AG, Soudal N.V., Wacker Chemie AG, etc. |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Benefits for Stakeholders:

- IMARC’s report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the high temperature sealant market from 2019-2033.

- The research study provides the latest information on the market drivers, challenges, and opportunities in the global high temperature sealant market.

- The study maps the leading, as well as the fastest-growing, regional markets. It further enables stakeholders to identify the key country-level markets within each region.

- Porter's Five Forces analysis assists stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the high temperature sealant industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Key Questions Answered in This Report

The high temperature sealant market was valued at USD 3.93 Billion in 2024.

The high temperature sealant market was valued at USD 5.55 Billion in 2033, exhibiting a CAGR of 3.60% during 2025-2033.

Key factors driving the high-temperature sealant market include growing demand from automotive, aerospace, and electronics sectors, technological advancements in manufacturing, the need for durable, heat-resistant materials, and rising industrial production. Additionally, increasing infrastructure development and the shift toward energy-efficient systems further fuel the market's growth.

Asia Pacific dominates the high-temperature sealant market due to rapid industrialization, a strong automotive and aerospace sector, and growing demand from electronics and manufacturing industries. Countries like China, Japan, and India lead in automotive production, electronics manufacturing, and infrastructure development, driving the region's demand for high-performance sealants.

Some of the major players in the high temperature sealant market include 3M Company, American Sealants Inc., Arkema S.A., Dow Inc., H.B. Fuller Company, Henkel AG & Co. KGaA, Illinois Tool Works Inc., Mapei S.p.A., PPG Industries Inc., Sika AG, Soudal N.V., Wacker Chemie AG, etc.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)