India Industrial Welding Machines Market Size, Share, Trends and Forecast by Welding Technology, Automation Level, Power Source Type, Sales Channel, End Use Industry, and Region, 2025-2033

India Industrial Welding Machines Market Size and Share:

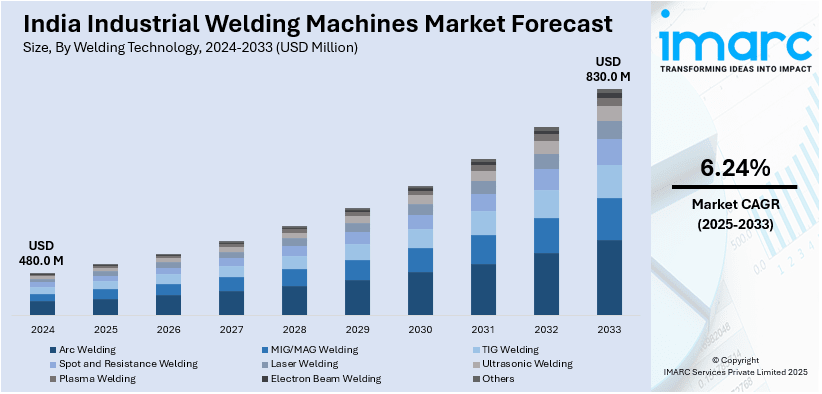

The India industrial welding machines market size reached USD 480.0 Million in 2024. Looking forward, IMARC Group expects the market to reach USD 830.0 Million by 2033, exhibiting a growth rate (CAGR) of 6.24% during 2025-2033. The market is propelled by rapid infrastructure growth, expanding automotive and construction industries, evolution of welding technologies, and accelerating demand for automated welding technology. Government policies encouraging manufacturing, foreign investment, and the use of Industry 4.0 also fuel the market growth.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2024

|

|

Forecast Years

|

2025-2033

|

|

Historical Years

|

2019-2024

|

| Market Size in 2024 | USD 480.0 Million |

| Market Forecast in 2033 | USD 830.0 Million |

| Market Growth Rate 2025-2033 | 6.24% |

India Industrial Welding Machines Market Trends:

Technological Advancements in Welding Equipment

Technological advancements in welding technology are enhancing the performance of Indian industrial welding machines. Sophisticated systems with capabilities such as real-time monitoring, adaptive control, and remote diagnostics are allowing welding to become more efficient and safer. Development in laser welding, friction stir welding, and hybrid welding processes is allowing industries to weld hard-to-weld materials with better accuracy. Also, the application of Industry 4.0 technologies like artificial intelligence (AI) and Internet of Things (IoT) supports predictive maintenance and data-driven decision-making. This technological advancement is particularly useful in sectors like aerospace, shipbuilding, and energy, where the weld quality should be high so that the operation can be reliable and safe. For instance, in February 2024, System India unveiled a new series of advanced welding machines aimed at improving precision and efficiency. Equipped with automation features, these machines ensure consistent, high-quality welds. Introduced in Delhi, the launch highlights System India’s dedication to driving technological innovation in the welding sector.

To get more information of this market, Request Sample

Growth in Infrastructure and Construction Projects

India's high-speed urbanization and mega infrastructure plans are driving demand for industrial welding machines. Government programs such as the National Infrastructure Pipeline (NIP) and Smart Cities Mission are pushing massive bridge, highway, railway, and industrial plant construction. Heavy machinery and construction equipment manufacturers depend heavily on strong welding solutions to guarantee structural strength and durability. In addition, increased renewable energy initiatives such as wind and solar power require specialized welding processes for structural mounting and turbine equipment. Increasing emphasis on eco-friendly construction is also promoting energy-saving welding solutions, further facilitating market growth. For instance, in February 2025, Ador Welding Limited launched the Rhino E, India’s first battery-powered electric welder. It offers 200 amps on battery and 400 amps on 3-phase power, emphasizing reduced carbon emissions and noise. The portable welder enhances efficiency with fast-charging capability. Developed by Ador’s Technical Development Centre, Rhino E reflects the company's commitment to sustainability and innovation under the Make in India initiative.

India Industrial Welding Machines Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the region/country level for 2025-2033. Our report has categorized the market based on welding technology, automation level, power source type, sales channel, and end use industry.

Welding Technology Insights:

- Arc Welding

- MIG/MAG Welding

- TIG Welding

- Spot and Resistance Welding

- Laser Welding

- Ultrasonic Welding

- Plasma Welding

- Electron Beam Welding

- Others

The report has provided a detailed breakup and analysis of the market based on the welding technology. This includes arc welding, MIG/MAG welding, TIG welding, spot and resistance welding, laser welding, ultrasonic welding, plasma welding, electron beam welding, and others.

Automation Level Insights:

- Manual Welding Machines

- Semi-Automatic Welding Machines

- Fully Automatic Welding Machines

A detailed breakup and analysis of the market based on the automation level have also been provided in the report. This includes manual welding machines, semi-automatic welding machines, and fully automatic welding machines.

Power Source Type Insights:

- Electric Welding Machines

- Gas Welding Machines

- Hybrid Welding Machines

A detailed breakup and analysis of the market based on the power source type have also been provided in the report. This includes electric welding machines, gas welding machines, and hybrid welding machines.

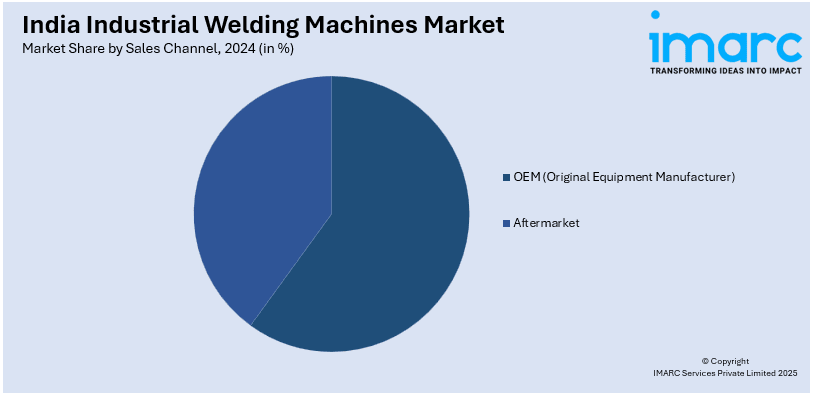

Sales Channel Insights:

- OEM (Original Equipment Manufacturer)

- Aftermarket

A detailed breakup and analysis of the market based on the sales channel have also been provided in the report. This includes OEM (original equipment manufacturer) and aftermarket.

End Use Industry Insights:

- Automotive

- Transportation

- Construction and Infrastructure

- Shipbuilding

- Aerospace and Defense

- Oil and Gas

- Energy and Power

- Heavy Machinery and Equipment

- Others

A detailed breakup and analysis of the market based on the end use industry have also been provided in the report. This includes automotive, transportation, construction and infrastructure, shipbuilding, aerospace and defense, oil and gas, energy and power, heavy machinery and equipment, and others.

Regional Insights:

- North India

- South India

- East India

- West India

The report has also provided a comprehensive analysis of all the major regional markets, which include North India, South India, East India, and West India.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

India Industrial Welding Machines Market News:

- In November 2024, ESAB entered into an agreement to acquire Linde Industries Private Limited (LIPL), a leading company in Bangladesh's welding sector. This strategic acquisition enhances ESAB’s market presence across South Asia.

- In February 2025, voestalpine Böhler Welding expanded its presence in India with a EUR 3 Million investment to improve local production of welding consumables and application technology. The company also plans to introduce solid wire production to support the “Make-in-India” initiative, targeting growth in the energy, construction, and transportation sectors.

India Industrial Welding Machines Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2024 |

| Historical Period | 2019-2024 |

| Forecast Period | 2025-2033 |

| Units | Million USD |

| Scope of the Report |

Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Welding Technologies Covered | Arc Welding, MIG/MAG Welding, TIG Welding, Spot and Resistance Welding, Laser Welding, Ultrasonic Welding, Plasma Welding, Electron Beam Welding, Others |

| Automation Levels Covered | Manual Welding Machines, Semi-Automatic Welding Machines, Fully Automatic Welding Machines |

| Power Source Types Covered | Electric Welding Machines, Gas Welding Machines, Hybrid Welding Machines |

| Sales Channels Covered | OEM (Original Equipment Manufacturer), Aftermarket |

| End Use Industries Covered | Automotive, Transportation, Construction and Infrastructure, Shipbuilding, Aerospace and Defense, Oil and Gas, Energy and Power, Heavy Machinery and Equipment, Others |

| Regions Covered | North India, South India, East India, West India |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the India industrial welding machines market performed so far and how will it perform in the coming years?

- What is the breakup of the India industrial welding machines market on the basis of welding technology?

- What is the breakup of the India industrial welding machines market on the basis of automation level?

- What is the breakup of the India industrial welding machines market on the basis of power source type?

- What is the breakup of the India industrial welding machines market on the basis of sales channel?

- What is the breakup of the India industrial welding machines market on the basis of end use industry

- What are the various stages in the value chain of the India industrial welding machines market?

- What are the key driving factors and challenges in the India industrial welding machines market?

- What is the structure of the India industrial welding machines market and who are the key players?

- What is the degree of competition in the India industrial welding machines market?

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the India industrial welding machines market from 2019-2033.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the India industrial welding machines market.

- Porter's Five Forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the India industrial welding machines industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)