India Naphthalene Market Size, Share, Trends and Forecast by Source, Grade, End User, and Region, 2025-2033

India Naphthalene Market Size and Share:

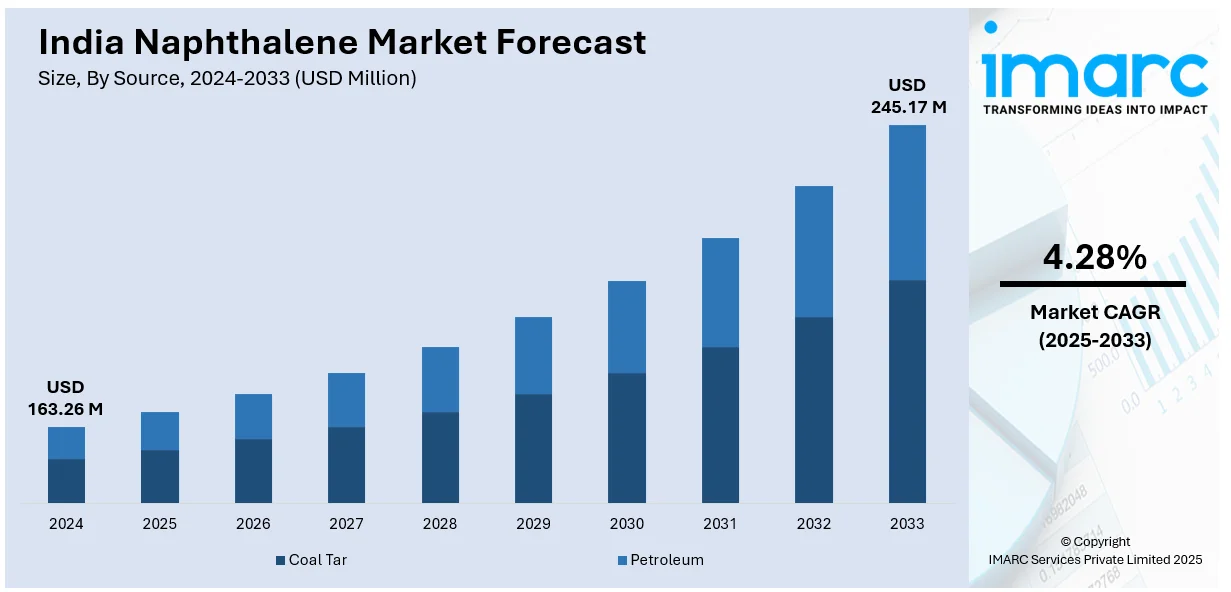

The India naphthalene market size reached USD 163.26 Million in 2024. Looking forward, IMARC Group expects the market to reach USD 245.17 Million by 2033, exhibiting a growth rate (CAGR) of 4.28% during 2025-2033 The market is driven by rising demand from construction, paints, and agrochemical sectors, fueled by infrastructure growth and urbanization. Additionally, the need for phthalic anhydride in plasticizers and resins enhances consumption. Moreover, tightening environmental regulations is pushing manufacturers toward bio-based alternatives, expanding the India naphthalene market share. Capacity expansion and sustainability initiatives further influence growth.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2024

|

|

Forecast Years

|

2025-2033

|

|

Historical Years

|

2019-2024

|

| Market Size in 2024 | USD 163.26 Million |

| Market Forecast in 2033 | USD 245.17 Million |

| Market Growth Rate (2025-2033) | 4.28% |

India Naphthalene Market Trends:

Rising Demand from the Construction and Paints Industry

The increasing demand from the construction and paint industries is significantly supporting the Indian naphthalene market growth. Naphthalene is a key raw material in the production of phthalic anhydride, which is used to manufacture plasticizers, alkyd resins, and coatings. With India's booming infrastructure development, rapid urbanization, and implementation of government initiatives, including Housing for All and Smart Cities Mission, the demand for paints, adhesives, and construction chemicals is on the rise. According to an industry report, India has achieved great strides in infrastructure development and technology, with INR 10 Lakh Crore (approximately USD 125,000 Million) allocated for the fiscal year 2023-24, predominantly focused on roadways, railways, and aviation. Forty-four ministries are consolidated under the PM Gati Shakti National Master Plan, facilitating 208 major infrastructure projects estimated at INR 15.39 Lakh Crore (approximately USD 192,375 Million). In addition to this, projects such as the Bharatmala Pariyojana and the Smart Cities Mission are improving connectivity, with the railway network increasing by 25,871 route kilometers between 2014 and 2023, thereby promoting the advanced construction industry across the country. The growth of the construction sector, in turn, is driving the consumption of naphthalene-based products. Additionally, the growing preference for high-performance coatings in residential and commercial buildings is further propelling market expansion. Manufacturers are focusing on enhancing production capacities to meet this rising demand, while also exploring sustainable alternatives to maintain environmental compliance. As construction activities continue to rise, the naphthalene market is expected to witness steady growth in the coming years.

To get more information on this market, Request Sample

Shift Towards Bio-Based Alternatives and Environmental Regulations

The increasing shift towards bio-based alternatives due to stringent environmental regulations is creating a positive India naphthalene market outlook. Naphthalene, a derivative of coal tar, is associated with environmental and health concerns, prompting regulatory bodies to impose stricter norms on its usage. Companies are investing in research and development (R&D) activities to produce eco-friendly substitutes, such as bio-based naphthalene and green solvents, to align with sustainability goals. A recent study has reported that naphthalene can be effectively synthesized from renewable feedstocks such as furfural and olefins using MFI zeolite-based catalysts that gave the highest yield of naphthalene (27.4%). However, this process is much more sustainable since it uses biomass-derived compounds and can revolutionize naphthalene production. As India shifts toward an increasing demand for sustainable chemicals, this development can have a significant impact on the country's naphthalene industry, offering an environmentally friendly alternative to traditional production processes. Additionally, the government's push for cleaner production processes under initiatives such as the National Chemical Policy is encouraging manufacturers to adopt greener technologies. While traditional naphthalene remains in demand for industrial applications, the market is gradually transitioning towards sustainable solutions. This shift is expected to reshape the competitive landscape, with companies that innovate in bio-based products gaining a competitive edge in the long term.

India Naphthalene Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the country level for 2025-2033. Our report has categorized the market based on source, grade, and end user.

Source Insights:

- Coal Tar

- Petroleum

The report has provided a detailed breakup and analysis of the market based on the source. This includes coal tar and petroleum.

Grade Insights:

- Technical Grade

- Special Grade

- Reagent Grade

- Scintillation Grade

A detailed breakup and analysis of the market based on the grade have also been provided in the report. This includes technical grade, special grade, reagent grade, and scintillation grade.

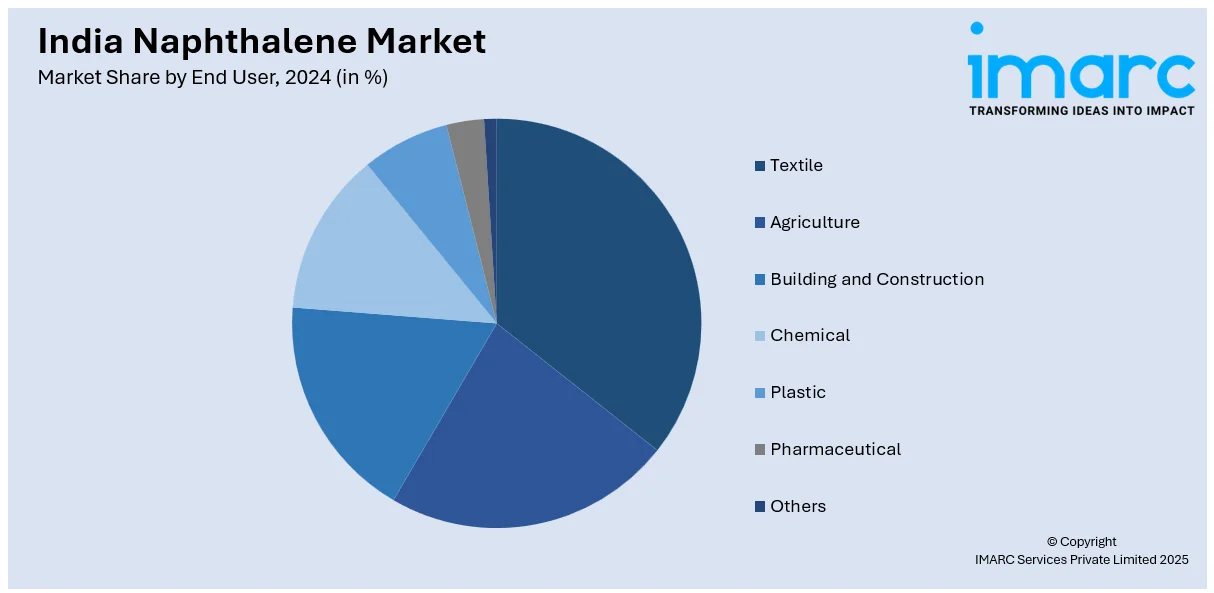

End User Insights:

- Textile

- Agriculture

- Building and Construction

- Chemical

- Plastic

- Pharmaceutical

- Others

The report has provided a detailed breakup and analysis of the market based on the end user. This includes textile, agriculture, building and construction, chemical, plastic, pharmaceutical, and others.

Regional Insights:

- North India

- South India

- East India

- West India

The report has also provided a comprehensive analysis of all the major regional markets, which include North India, South India, East India, and West India.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

India Naphthalene Market News:

- In January 2025, the Odisha government approved investment proposals amounting to INR 4,222.24 crore (about USD 4.92 Billion) across 25 industrial projects. Among these, Utkal Hydrocarbon Pvt. Ltd. in Jharsuguda has been allocated INR 63.02 crore (about USD 7.35 Million) for the establishment of a manufacturing unit specializing in coal tar pitch, dehydrated coal tar, and naphthalene. These projects encompass a diverse range of sectors, including green energy equipment, chemicals, pharmaceuticals, textiles, plastics, food processing, and downstream aluminum. The initiatives will be implemented across 11 districts, including Angul, Ganjam, Khordha, and Sambalpur.

India Naphthalene Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2024 |

| Historical Period | 2019-2024 |

| Forecast Period | 2025-2033 |

| Units | Million USD |

| Scope of the Report |

Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Sources Covered | Coal Tar, Petroleum |

| Grades Covered | Technical Grade, Special Grade, Reagent Grade, Scintillation Grade |

| End Users Covered | Textile, Agriculture, Building and Construction, Chemical, Plastic, Pharmaceutical, Others |

| Regions Covered | North India, South India, East India, West India |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the India naphthalene market from 2019-2033.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the India naphthalene market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the India naphthalene industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Key Questions Answered in This Report

The naphthalene market in India was valued at USD 163.26 Million in 2024.

The naphthalene market in India is projected to exhibit a CAGR of 4.28% during 2025-2033, reaching a value of USD 245.17 Million by 2033.

The growth of the construction, paints, and agrochemical sectors, driven by urbanization and infrastructure development, is significantly driving the demand for naphthalene. Additionally, the rising need for phthalic anhydride in plasticizers and resins, alongside tightening environmental regulations pushing for bio-based alternatives, are key growth factors.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)