Metal Beam Crash Barrier and High Mast Lightning Pole Cost Model: Building Safer and Smarter Infrastructure

_11zon-(1).webp)

What is Metal Beam Crash Barrier and High Mast Lightning Pole?

Metal beam crash barriers and high mast light poles are essential infrastructural features providing security and visibility on highways, city roads, and industrial sites. Metal beam crash barriers or guardrails are made of galvanized steel beams, typically W-beam or Thrie-beam, that are designed to dissipate the impact energy on impact with a vehicle and minimize death and damage to vehicles. Their major characteristics are tensile strength, resistance to corrosion, and longevity, for which they are unsupportable for road safety. High mast light poles, however, are towering steel structures meant to hold assemblies of high-intensity luminaires, lighting up huge areas like highways, stadiums, airports, and industrial estates.

Key Applications Across Industries:

Made from high-quality steel and subjected to corrosion treatment, these poles are designed to remain steady against wind pressures, seismic activity, and weather conditions. Both products provide economic and social advantages by mitigating risks of accidents, facilitating smooth traffic flow, and ensuring safe night-time visibility. As investments rise in smart cities, road safety programs, and upgrading infrastructure, demand prospects for metal beam crash barriers and high mast lighting poles continue to look optimistic with sustainability drivers like recyclability of steel and incorporating energy-efficient luminaries. The demand for metal beam crash barriers and high mast lighting poles is influenced by robust infrastructure development drivers.

What the Expert Says: Market Overview & Growth Drivers

The India metal beam crash barrier market size reached INR 49,225 Million in 2024. According to IMARC Group, the market is projected to reach INR 76,126 Million by 2033, at a projected CAGR of 4.8% during 2025-2033. The India high mast lightning pole market size reached INR 10,012 Million in 2024. According to IMARC Group, the market is projected to reach INR 16,614 Million by 2033, at a projected CAGR of 5.7% during 2025-2033. Increased highway, expressway, and urban mobility project investments generate steady demand for crash barriers as the government imposes tight road safety standards.

Industrial and urban development also fuels demand for high mast lighting poles, securing improved visibility in public and commercial areas. The use of LED luminaires and intelligent control systems in high mast lighting is a future-oriented trend for the next five years, bringing energy efficiency and remote monitoring. Crash barriers are also being developed with improved coatings and modular designs for quicker installation and increased longevity. The competitive advantages are gain in recyclability, low maintenance, and conformity to international safety standards. Threats encompass steel price volatility and delays in projects through regulatory challenges. From a sustainability standpoint, galvanized steel poles and barriers provide high recovery rates with extended life cycles. Industry measures involve strategic public-private alliances, R&D of environmentally friendly coatings, and the use of renewable-powered lighting systems to serve sustainable infrastructure development objectives.

Case Study on Cost Model of Metal Beam Crash Barrier and High Mast Lightning Pole Manufacturing Plant:

Objective

One of our clients reached out to us to conduct a feasibility study for setting up a medium to large-scale metal beam crash barrier and high mast lightning pole manufacturing plant.

IMARC Approach: Comprehensive Financial Feasibility

We developed a comprehensive financial model for the setup and operation of a proposed metal beam crash barrier and high mast lightning pole manufacturing plant in India. This plant is designed to produce 3,500 tons of metal beam crash barrier and 1,500 tons of high mast lightning pole monthly.

Manufacturing Process: Production of metal beam crash barriers is a systematic process intended to provide strength, endurance, and conformity to safety standards. It is initiated with raw material preparation where mild steel coils or sheet metal, usually conforming to FE-410 specifications, are chosen for strength and weldability with galvanized steel being the preferred material to improve corrosion resistance. Following surface inspection for any defects or irregularities, the steel is decoiled and flattened to give smooth sheets ready for accurate cutting. The sheets are then sheared or cut to specifications in terms of length and punched and slotted to form holes and openings to facilitate assembly. Then, the sections are roll formed, a continuous process in which steel is incrementally formed into the distinctive W-beam or Thrie-beam shapes, maintaining consistency and strength. For corrosion protection, the beams are hot-dip galvanized, covering them in zinc for durable, long-term protection in outdoor conditions. Stringent inspection and quality control ensue, confirming dimensions, hole location, coating thickness, and surface finish. Other elements like posts, spacers, end terminals, and bolts are produced or procured to finish the system. Lastly, beams and accessories are properly packaged, labeled, and shipped for secure delivery to building sites where they are set as essential road safety infrastructure.

High mast lighting poles production entails a series of accurate procedures to provide strength, durability, and adherence to safety standards. The production process required starts with material choice, and in this case, mild steel is the material of choice due to its strength and capacity to carry high wind loads. The steel sheets are subsequently machined using a shearing system, where raw sheets are supplied, aligned, and clamped and then cut using a disc slitting shear with high-strength alloy blades, resulting in tapered sections suitable for forming conical poles. Then, during the welding and forming process, the cut sheets are formed into polygonal or conical profiles through roll forming or press brake machines. The edges are welded lengthwise by submerged arc welding (SAW) or MIG welding to obtain seamless strength, and base flanges and bracket mounts are welded to finish the structure. Then, surface preparation and finishing are done, which most commonly involve hot-dip galvanizing against corrosion and optional powder coating for added strength and appearance. Strict quality control and inspection then ensue, such as measurement checking, weld inspection, surface inspection, and load/wind resistance simulation. Lastly, the poles are packaged and sent, with special care in labeling and cushioning against transit damage to allow for sure delivery for installation.

Process-1

_11zon.webp)

Process-2

_11zon.webp)

Mass Balance and Raw Material Required: The primary raw materials used in the metal beam crash barrier producing plant are HR coil, zinc ingot, degreaser, hydrochloric acid, flux and sodium dichromate. For a plant producing 1 ton of W-Beam crash barrier, 1.1 ton of HR coil, 0.06 ton of zinc ingot, 0.002 ton of degreaser, 0.05 ton of hydrochloric acid, 0.002 ton of flux, and 0.0003 ton of sodium dichromate are required. Additionally, for a plant producing 1 ton of Thrie crash barrier, 1.1 ton of HR coil, 0.06 ton of zinc ingot, 0.002 ton of degreaser, 0.05 ton of hydrochloric acid, 0.002 ton of flux, and 0.0003 ton of sodium dichromate are required.

The primary raw materials used in the high mast lightning pole producing plant are HR coil, zinc ingot, degreaser, hydrochloric acid, flux and sodium dichromate. For a plant producing 1 ton of 30-meter-high mast lightning pole, 1.2 ton of HR coil, 0.05 ton of zinc ingot, 0.002 ton of degreaser, 0.05 ton of hydrochloric acid, 0.002 ton of flux, and 0.0003 ton of sodium dichromate are required. Further, for a plant producing 1 ton of 30-meter-high mast lightning pole, 1.2 ton of HR coil, 0.05 ton of zinc ingot, 0.002 ton of degreaser, 0.05 ton of hydrochloric acid, 0.002 ton of flux, and 0.0003 ton of sodium dichromate are required.

Techno-Commercial Parameter:

- Capital Investment (CapEx): Capital expenditure (CapEx) in a manufacturing plant includes various investments essential for its setup and long-term operations. It covers machinery and equipment costs, including procurement, installation, and commissioning. Civil works expenses involve land development, factory construction, and infrastructure setup. Utilities such as power, water supply, and HVAC systems are also significant. Additionally, material handling systems, automation, environmental compliance, and safety measures are key components. Other expenditures include IT infrastructure, security systems, and office essentials, ensuring operational efficiency and business growth.

- Operating Expenditure (OpEx): Operating expenditure is the cost incurred to operate a manufacturing plant effectively. OpEx in a manufacturing plant typically includes the cost of raw materials, utilities, depreciation, taxes, packing cost, transportation cost, and repairs and maintenance. The operating expenses are part of the cost structure of a manufacturing plant and have a significant effect on profitability and efficiency. Effective control of these costs is necessary for maintaining competitiveness and growth.

.webp)

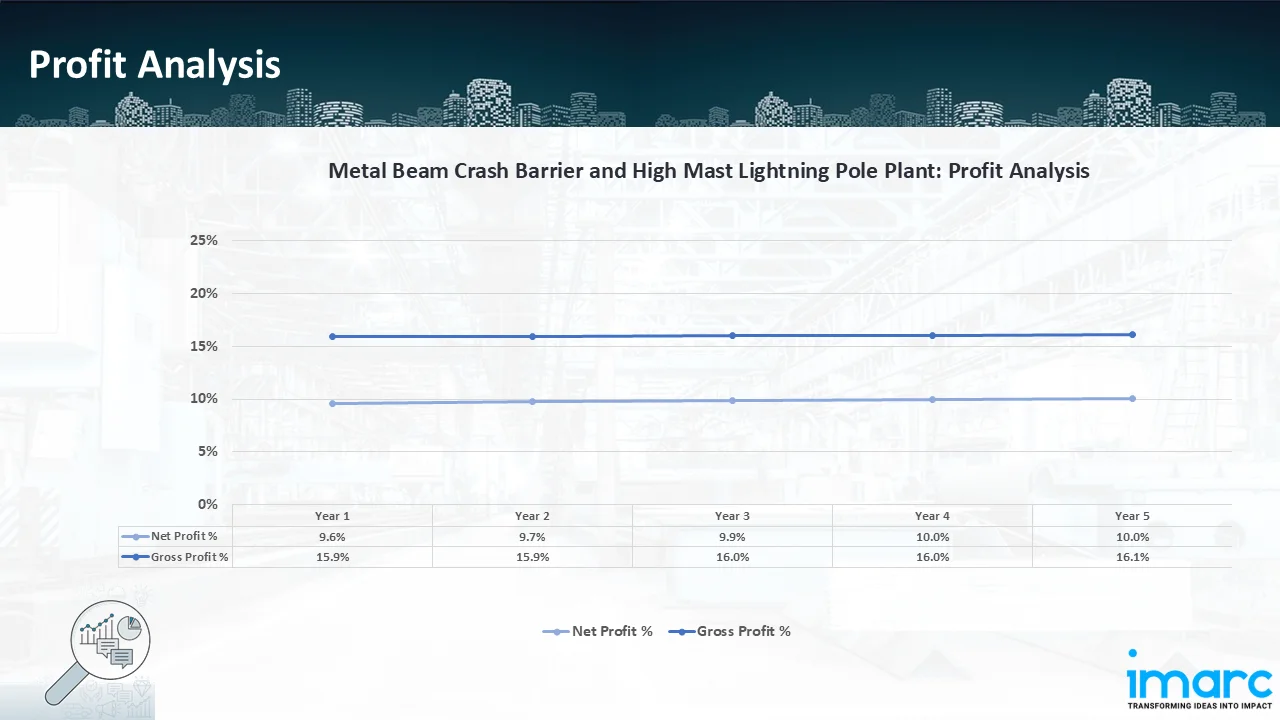

- Profitability Analysis Year on Year Basis: The proposed plant, with a capacity of 3,500 tons of metal beam crash barrier and 1,500 tons of high mast lightning pole monthly, achieved an impressive revenue of INR 3.9 billion in its first year. We assisted our client in developing a detailed cost model, which projects steady growth, with revenue rising throughout the projected period. Moreover, gross profit margins improve from 15.9% to 16.1% by year 5, and net profit rises from 9.6% to 10.0%, highlighting strong financial viability and profitability.

Conclusion & IMARC's Impact:

Our financial model for the metal beam crash barrier and high mast lightning pole manufacturing plant was meticulously developed to meet the client’s objectives, providing an in-depth analysis of production costs, including raw materials, manufacturing, capital expenditure, and operational expenses. By addressing the specific requirements of producing 3,500 tons of metal beam crash barrier and 1,500 tons of high mast lightning pole monthly, we successfully identified key cost drivers and projected profitability, considering market trends, inflation, and potential fluctuations in raw material prices. This comprehensive financial model equipped the client with valuable insights into strategic decision-making, demonstrating our commitment to delivering high-quality, client-focused solutions that ensure the long-term success of large-scale manufacturing ventures.

Latest News and Developments:

- In September 2025, the integrated metal band Shyam Metalics declared that it will start producing crash barriers, which are safety structures for the side of the road composed of concrete or steel. The corporation stated that its goal with this venture is to gain 8–10% of the market in FY 2025–2026.

- In July 2025, Barrier1 Systems LLC, a nationally renowned leader in crash-rated car barrier solutions, has formally announced its choice to stay in Guilford County, North Carolina. Greensboro's increasing standing as a centre for homeland security innovation and advanced manufacturing will be strengthened by the company's growth, which will represent a major investment in the area.

- In January 2025, policy circular was released by the National Highways Authority of India (NHAI) to rectify inconsistencies in the installation and authorisation of Metal Beam Crash Barriers (MBCB) on national highways. It implements strict measures to guarantee adherence to safety procedures and technical standards.

Why Choose IMARC:

IMARC's Financial Model Expertise: Helping Our Clients Explore Industry Economics

IMARC is a global market research company that offers a wide range of services, including market entry and expansion, market entry and opportunity assessment, competitive intelligence and benchmarking, procurement research, pricing and cost research, regulatory approvals and licensing, factory setup, factory auditing, company incorporation, incubation services, recruitment services, and marketing and sales.

Under our factory setup services, we assist our clients in exploring the feasibility of their plants by providing comprehensive financial modeling. Additionally, we offer end-to-end consultation for setting up a plant in India or abroad. Our financial modeling includes an analysis of capital expenditure (CapEx) required to establish the manufacturing facility, covering costs such as land acquisition, building infrastructure, purchasing high-tech production equipment, and installation. Furthermore, the layout and design of the factory significantly influence operational efficiency, energy consumption, and labor productivity, all of which impact long-term operational expenditure (OpEx). So, every parameter is covered in the analysis.

At IMARC, we leverage our comprehensive market research expertise to support companies in every aspect of their business journey, from market entry and expansion to operational efficiency and innovation. By integrating our factory setup services with our deep knowledge of industry dynamics, we empower our clients to not only establish manufacturing facilities but also strategically position themselves in highly competitive markets. Our financial modeling and end-to-end consultation services ensure that clients can explore the feasibility of their plant setups while also gaining insights into competitors' strategies, technological advancements, and regulatory landscapes. This holistic approach enables our clients to make informed decisions, optimize their operations, and align with sustainable practices, ultimately driving long-term success and growth.

Our Clients

Contact Us

Have a question or need assistance?

Please complete the form with your inquiry or reach out to us at

Phone Number

+91-120-433-0800+1-201-971-6302

+44-753-714-6104