Japan Concrete Reinforcement Market Size, Share, Trends and Forecast by Product Type, Application, and Region, 2026-2034

Japan Concrete Reinforcement Market Overview:

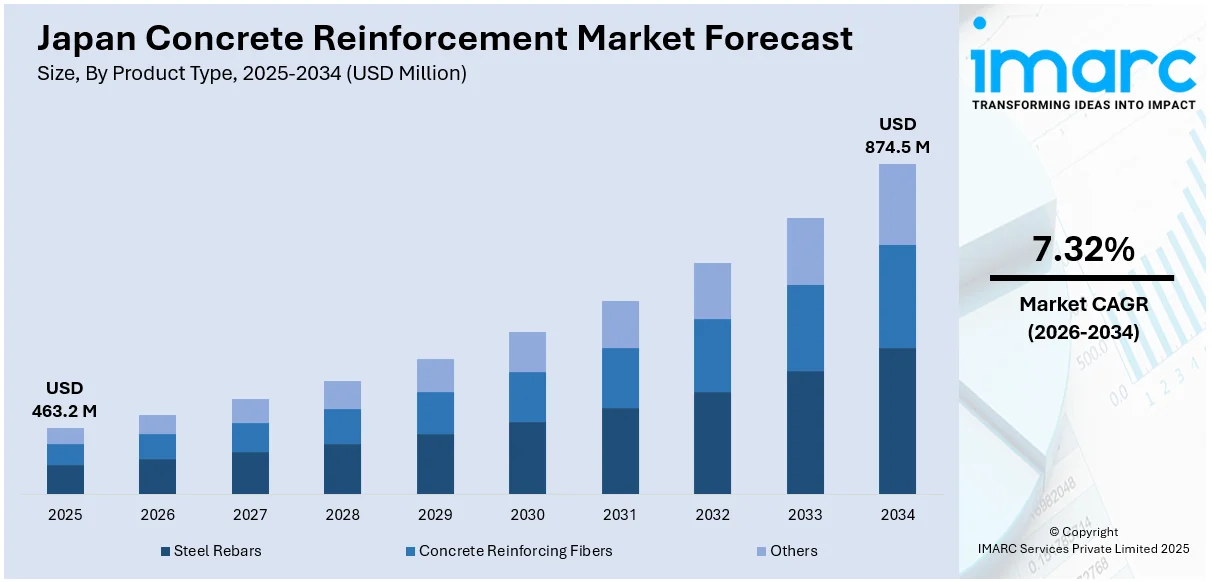

The Japan concrete reinforcement market size reached USD 463.2 Million in 2025. Looking forward, IMARC Group expects the market to reach USD 874.5 Million by 2034, exhibiting a growth rate (CAGR) of 7.32% during 2026-2034. The market includes the country’s high seismic activity, prompting demand for earthquake-resilient construction. Urban redevelopment and the need to upgrade aging infrastructure further fuel growth. Environmental awareness is pushing the adoption of sustainable and recycled materials, while labor shortages are accelerating the shift toward digital construction technologies like Building Information Modeling (BIM) and three-dimensional (3D) printing. Together, these factors are reshaping the Japan concrete reinforcement market share by promoting safer, more efficient, and eco-friendly building practices across public and private sectors.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2025

|

|

Forecast Years

|

2026-2034

|

|

Historical Years

|

2020-2025

|

|

Market Size in 2025

|

USD 463.2 Million |

|

Market Forecast in 2034

|

USD 874.5 Million |

| Market Growth Rate 2026-2034 | 7.32% |

Japan Concrete Reinforcement Market Trends:

Digitalization and 3D Concrete Printing Integration

Japan is adopting digital technology to revolutionize its construction and concrete reinforcement industries. As labor shortages become more prevalent and the need for precision and speed becomes greater, digital technologies such as BIM, automation, and robotics are becoming the norm. These technologies enhance planning on a project, eliminate errors, and facilitate communication between teams. One of the most notable innovations is 3D printing of concrete, through which intricate structural members can be quickly produced with minimum wastage and maximum design freedom. This process is being coupled with reinforcement measures so as to achieve structural integrity with maximum material efficiency. Developers also experiment with intelligent building sites, where data analysis and on-site monitoring make building safer, more efficient. Digitalization is not just improving construction quality, but also promoting sustainability and cost efficiency. With Japan's transition to a technology-driven society, the use of smart tools and advanced reinforcement techniques is changing the way infrastructure is constructed and maintained.

To get more information on this market Request Sample

Seismic-Resilient Reinforcement and Infrastructure Modernization

Japan's placement on the tectonic fault line necessitates earthquake resistance as the utmost priority for construction. Accordingly, advanced reinforcement materials and systems have been widely adopted by the country, including base isolation and energy-absorbing dampers, to create stronger and more flexible buildings. These are applied in urban redevelopment projects, upgrading aging infrastructure, and new buildings on public buildings, residential homes, schools, and business properties. Seismic-isolated reinforced concrete buildings are nowadays not only designed to resist seismic shakings but also to minimize damage and facilitate rapid recovery. Demonstrating that commitment, as of 2024, Japan boasts more than 5,000 seismically isolated buildings, ranging from offices, condominiums, and hospitals to detached houses with the number well over 10,000 if all detached homes are included. Japanese engineers continually innovate construction methods to weigh safety against design, so reinforced concrete solutions are central to constructing a safer, more resilient, and sustainable urban environment.

Sustainability and Green Steel Innovation

Japan’s concrete reinforcement market is increasingly driven by a commitment to environmental sustainability. With growing awareness around climate change and resource conservation, developers are turning to eco-friendly construction materials and processes. Recycled steel and energy-efficient manufacturing methods are now common in producing reinforcement bars. Construction companies are also incorporating sustainable design principles that minimize waste and reduce environmental impact over the building lifecycle. This green shift is not just a response to regulations it reflects a broader cultural emphasis on harmony with nature and responsibility to future generations. In design and development, there’s a strong push toward using materials that offer durability while supporting environmental goals. The industry’s efforts to align with global green standards are also enhancing Japan concrete reinforcement market growth as a leader in responsible construction. These practices support both structural integrity and the long-term goal of a more eco-conscious built environment.

Japan Concrete Reinforcement Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the country and regional levels for 2026-2034. Our report has categorized the market based on product type and application.

Product Type Insights:

- Steel Rebars

- Concrete Reinforcing Fibers

- Polypropylene Fibers

- Steel Fibers

- Basalt Fibers

- Others

- Others

The report has provided a detailed breakup and analysis of the market based on the product type. This includes steel rebars, concrete reinforcing fibers (polypropylene fibers, steel fibers, basalt fibers, others), and others.

Application Insights:

Access the comprehensive market breakdown Request Sample

- Infrastructure

- Residential Construction

- Commercial Construction

- Industrial Construction

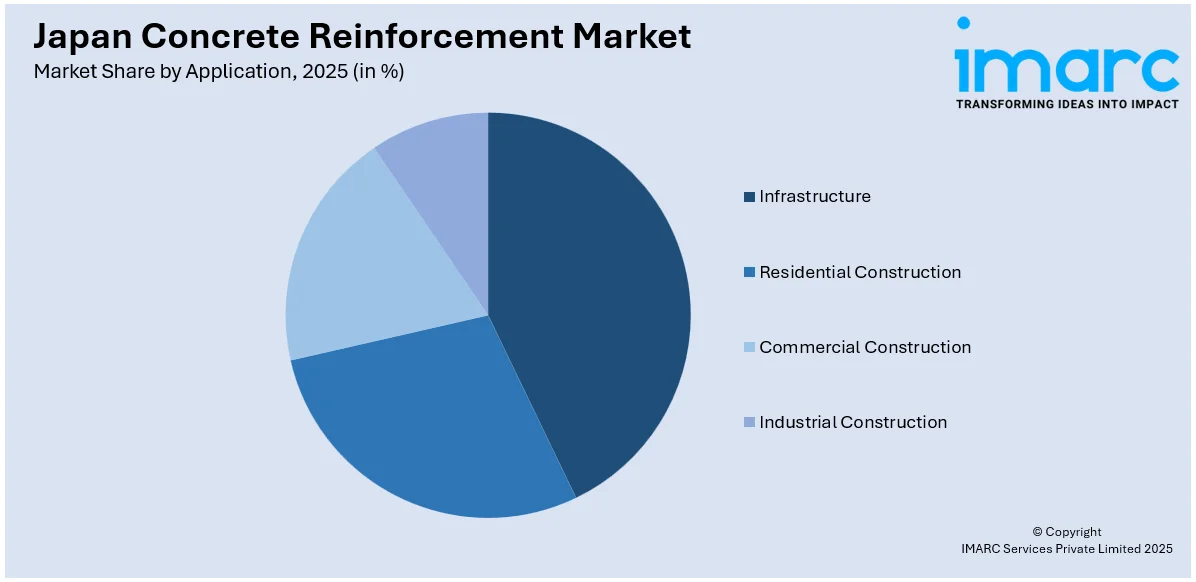

A detailed breakup and analysis of the market based on the application have also been provided in the report. This includes infrastructure, residential construction, commercial construction, and industrial construction.

Regional Insights:

- Kanto Region

- Kansai/Kinki Region

- Central/ Chubu Region

- Kyushu-Okinawa Region

- Tohoku Region

- Chugoku Region

- Hokkaido Region

- Shikoku Region

The report has also provided a comprehensive analysis of all the major regional markets, which include Kanto, Kansai/Kinki, Central/ Chubu, Kyushu-Okinawa, Tohoku, Chugoku, Hokkaido, and Shikoku Region.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

Japan Concrete Reinforcement Market News:

- In October 2024, ExxonMobil secured exclusive global licensing rights (outside North America) for Neuvokas Corporation’s patented GatorBar® composite rebar manufacturing process. By combining Neuvokas’ innovation with ExxonMobil’s Proxxima™ resin system, the partnership enables rapid, cost-effective production of corrosion-free, lightweight rebar. This advanced solution offers faster installation, easier handling, and improved durability—positioning it as a viable, high-performance alternative to traditional steel reinforcement in construction projects worldwide.

- In September 2024, Asahi Kasei Homes acquired Florida-based ODC Construction through its U.S. subsidiary, expanding its North American operations. This move strengthens its presence in high-demand housing markets, particularly Florida, while supporting its medium-term growth strategy. ODC, a major subcontractor specializing in framing and foundation work, brings operational efficiency and local expertise. The partnership aims to enhance construction quality and productivity by combining Asahi Kasei’s management strengths with ODC’s regional capabilities.

Japan Concrete Reinforcement Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2025 |

| Historical Period | 2020-2025 |

| Forecast Period | 2026-2034 |

| Units | Million USD |

| Scope of the Report |

Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Product Types Covered |

|

| Applications Covered | Infrastructure, Residential Construction, Commercial Construction, Industrial Construction |

| Regions Covered | Kanto Region, Kansai/Kinki Region, Central/ Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, and Shikoku Region |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the Japan concrete reinforcement market performed so far and how will it perform in the coming years?

- What is the breakup of the Japan concrete reinforcement market on the basis of product type?

- What is the breakup of the Japan concrete reinforcement market on the basis of application?

- What is the breakup of the Japan concrete reinforcement market on the basis of region?

- What are the various stages in the value chain of the Japan concrete reinforcement market?

- What are the key driving factors and challenges in the Japan concrete reinforcement market?

- What is the structure of the Japan concrete reinforcement market and who are the key players?

- What is the degree of competition in the Japan concrete reinforcement market?

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the Japan concrete reinforcement market from 2020-2034.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the Japan concrete reinforcement market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the Japan concrete reinforcement industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)