Japan Copper Pipes and Tubes Market Size, Share, Trends and Forecast by Finish Type, Outer Diameter, End User, and Region, 2026-2034

Japan Copper Pipes and Tubes Market Overview:

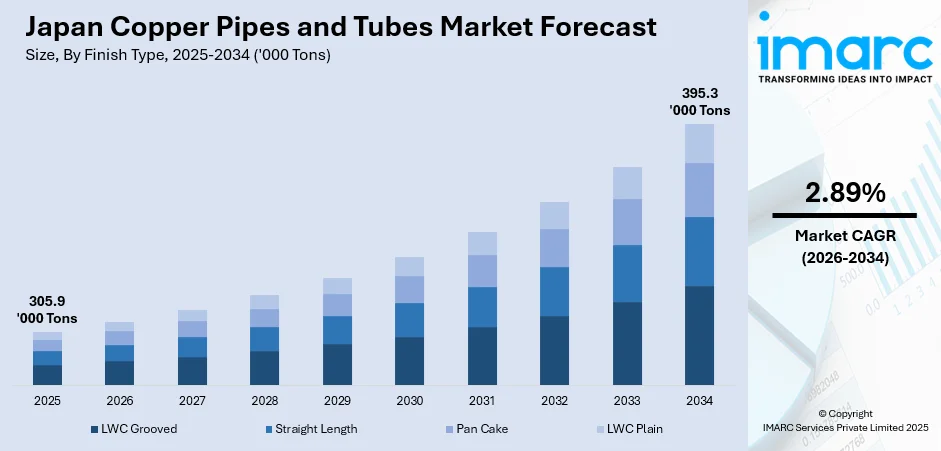

The Japan copper pipes and tubes market size reached 305.9 Thousand Tons in 2025. Looking forward, IMARC Group expects the market to reach 395.3 Thousand Tons by 2034, exhibiting a growth rate (CAGR) of 2.89% during 2026-2034. The rising demand from heating, ventilation and air conditioning (HVAC) and electronics sectors, increasing focus on energy-efficient infrastructure, and growth in electric vehicle (EVs) production. Additionally, government sustainability goals and a shift toward domestic manufacturing are encouraging innovation and strengthening supply chain resilience across the industry.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2025 |

|

Forecast Years

|

2026-2034

|

|

Historical Years

|

2020-2025

|

| Market Size in 2025 | 305.9 Thousand Tons |

| Market Forecast in 2034 | 395.3 Thousand Tons |

| Market Growth Rate 2026-2034 | 2.89% |

Japan Copper Pipes and Tubes Market Trends:

Rising Demand from HVAC and Electronics Sectors

In Japan, demand for copper pipes and tubes continues to grow, driven primarily by the HVAC and electronics industries. The country's aging infrastructure and the push for greater energy efficiency are fueling the installation of new HVAC systems in both residential and commercial settings. Copper’s superior thermal and electrical conductivity also makes it indispensable in electronics manufacturing. With the rise of electric vehicles (EVs), fifth generation (5G) networks, and advanced consumer electronics, the demand for precision-engineered copper components has surged. Reflecting this trend, Japan recorded one of the highest per capita consumption rates of copper pipes and fittings in the Asia-Pacific region in 2024, at 2.1 kg per person. This dual-sector growth is fostering continuous innovation as manufacturers adapt to increasingly specialized application requirements and evolving technology demands.

To get more information on this market Request Sample

Shift Towards Domestic Production and Supply Chain Resilience

In 2023, Japan imported $26.15 million worth of refined copper pipe and tube fittings, primarily from China and Thailand. However, the country is gradually shifting toward strengthening its domestic production to reduce reliance on foreign suppliers. This transition is being driven by ongoing global supply chain disruptions and a broader national initiative to bolster industrial resilience. By investing in local manufacturing, Japanese companies aim to secure a stable supply chain, reduce lead times, and uphold stringent quality standards. The push for domestic capability is also leading to technological upgrades in production facilities and encouraging stronger collaboration across the local industrial ecosystem. As a result, Japan is moving toward greater self-reliance in producing high-quality, precision-engineered copper components, particularly for sectors such as HVAC and electronics, where performance and consistency are critical thus aiding the Japan copper pipes and tubes market share.

Technological Advancements and Sustainability Initiatives

Japanese manufacturers of copper pipes and tubes are embracing advanced production technologies to meet evolving performance demands across sectors. A strong emphasis is being placed on developing copper variants that are lightweight, corrosion-resistant, and highly conductive ideal for applications in clean energy and electric mobility. Simultaneously, sustainability has become a core focus in manufacturing strategies. Companies are increasingly adopting eco-friendly practices, enhancing the use of recycled materials, and working toward minimizing carbon emissions further positively impacting the Japan copper pipes and tubes market outlook. Furukawa Electric Co., Ltd., for instance, achieved UL 2809 validation for copper foil made from 100% recycled copper, significantly lowering CO₂ emissions throughout the value chain. These efforts support Japan’s broader sustainability goals and position manufacturers to better serve environmentally conscious markets, strengthening long-term competitiveness and aligning with global expectations for greener, high-performance materials.

Japan Copper Pipes and Tubes Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the region level for 2026-2034. Our report has categorized the market based on finish type, outer diameter, and end user.

Finish Type Insights:

- LWC Grooved

- Straight Length

- Pan Cake

- LWC Plain

The report has provided a detailed breakup and analysis of the market based on the finish type. This includes LWC grooved, straight length, pan cake, and LWC plain.

Outer Diameter Insight

- 3/8, 1/2, 5/8 Inch

- 3/4, 7/8, 1 Inch

- Above 1 inch

A detailed breakup and analysis of the market based on the outer diameter have also been provided in the report. This includes 3/8, 1/2, 5/8 inch, 3/4, 7/8, 1 inch, and above 1 inch.

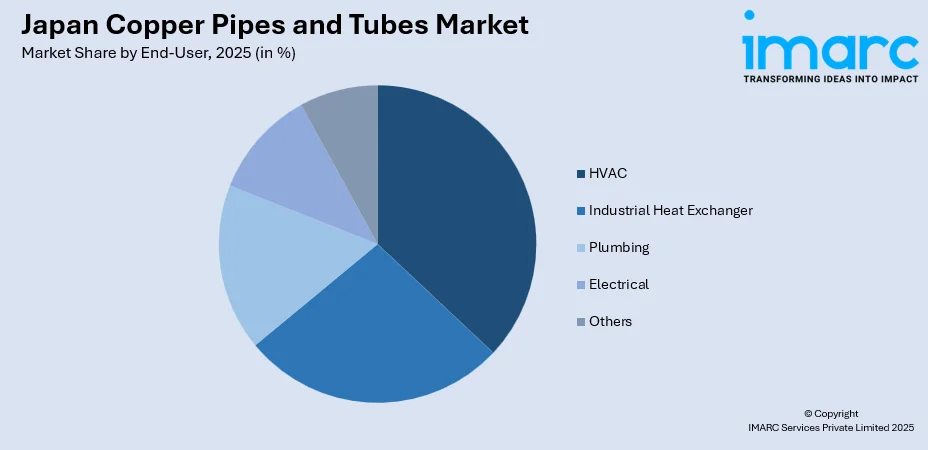

End-User Insight

Access the comprehensive market breakdown Request Sample

- HVAC

- Industrial Heat Exchanger

- Plumbing

- Electrical

- Others

The report has provided a detailed breakup and analysis of the market based on the end user. This includes HVAC, industrial heat exchanger, plumbing, electrical, and others.

Regional Insights:

- Kanto Region

- Kansai/Kinki Region

- Central/ Chubu Region

- Kyushu-Okinawa Region

- Tohoku Region

- Chugoku Region

- Hokkaido Region

- Shikoku Region

The report has also provided a comprehensive analysis of all the major regional markets, which include Kanto, Kansai/Kinki, Central/ Chubu, Kyushu-Okinawa, Tohoku, Chugoku, Hokkaido, and Shikoku Region.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

Japan Copper Pipes and Tubes Market News:

- In November 2024, Japan and Peru signed a strategic deal to strengthen the copper supply chain, aiming to enhance bilateral business opportunities and secure copper supplies. The 10-year roadmap, signed on November 17, 2024, includes joint research on efficient mining operations and annual meetings for mining and energy investment. Japan is seeking to boost its base metal self-sufficiency to 80% by 2030, with a focus on securing copper amid rising global demand, particularly from electric vehicles.

Japan Copper Pipes and Tubes Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2025 |

| Historical Period | 2020-2025 |

| Forecast Period | 2026-2034 |

| Units | Thousand Tons |

| Scope of the Report |

Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Finish Types Covered | LWC Grooved, Straight Length, Pan Cake, LWC Plain |

| Outer Diameters Covered | 3/8, 1/2, 5/8 Inch, 3/4, 7/8, 1 Inch, above 1 inch |

| End Users Covered | HVAC, Industrial Heat Exchanger, Plumbing, Electrical, Others |

| Regions Covered | Kanto Region, Kansai/Kinki Region, Central/ Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, Shikoku Region |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the Japan copper pipes and tubes market performed so far and how will it perform in the coming years?

- What is the breakup of the Japan copper pipes and tubes market on the basis of finish type?

- What is the breakup of the Japan copper pipes and tubes market on the basis of outer diameter?

- What is the breakup of the Japan copper pipes and tubes market on the basis of end user?

- What is the breakup of the Japan copper pipes and tubes market on the basis of region?

- What are the various stages in the value chain of the Japan copper pipes and tubes market?

- What are the key driving factors and challenges in the Japan copper pipes and tubes market?

- What is the structure of the Japan copper pipes and tubes market and who are the key players?

- What is the degree of competition in the Japan copper pipes and tubes market?

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the Japan copper pipes and tubes market from 2020-2034.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the Japan copper pipes and tubes market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the Japan copper pipes and tubes industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)