Japan Die Casting Market Size, Share, Trends and Forecast by Process, Raw Material, Application, and Region, 2026-2034

Japan Die Casting Market Overview:

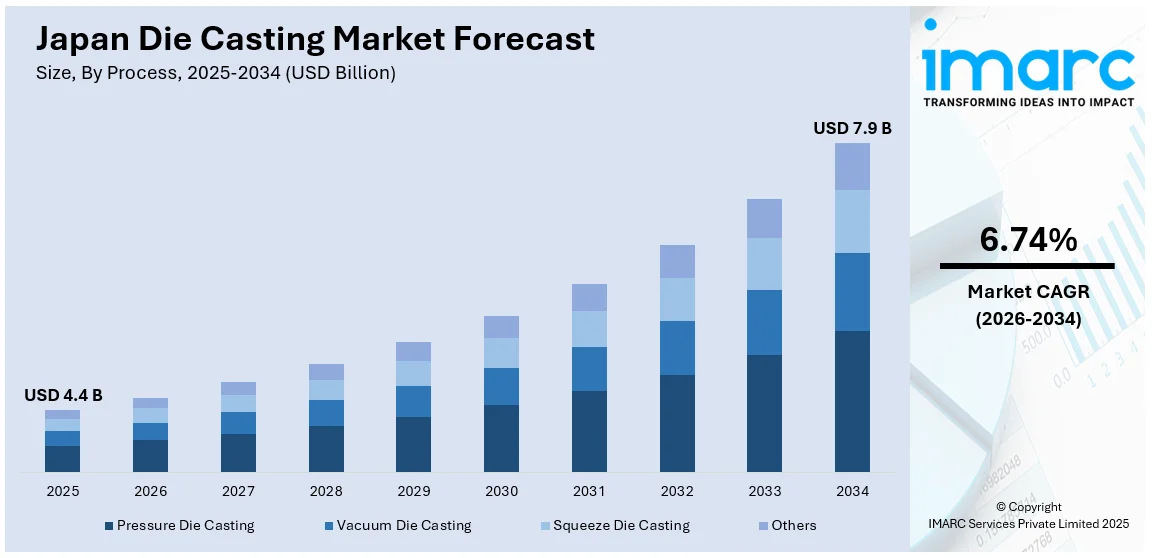

The Japan die casting market size reached USD 4.4 Billion in 2025. Looking forward, IMARC Group expects the market to reach USD 7.9 Billion by 2034, exhibiting a growth rate (CAGR) of 6.74% during 2026-2034. The market is driven by rising requirements for lightweight and tough components in automotive, electronics, and machinery industries. Rising utilization of electric vehicles (EVs) and environmental policies further increased the demand for die-cast components with advanced features. Furthermore, ongoing advancements in die-casting technologies and increasing manufacturing capacity further improve production capacity and quality of components, further expanding Japan die casting market share.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2025

|

|

Forecast Years

|

2026-2034

|

|

Historical Years

|

2020-2025

|

| Market Size in 2025 | USD 4.4 Billion |

| Market Forecast in 2034 | USD 7.9 Billion |

| Market Growth Rate 2026-2034 | 6.74% |

Japan Die Casting Market Trends:

Increase in Adoption of Light Metals in Die Casting

The increasing adoption of light metals, especially aluminum and magnesium, is creating a positive market outlook. Further, the rise in demand for light components in the automotive, aerospace, and electronics sectors fuels the usage. The lightweight materials are highly favored as they possess a high strength-to-weight ratio, and it is ideal for designing parts that need to be strong as well as lighter in weight. Hence, in the automotive sector, light metal die casting is employed to produce engine blocks, transmission cases, and other crucial components to meet the market demand for efficient fuel-burning, high-performance automobiles. Apart from this, these light metals also serve to complement Japan's general commitment to sustainability, with the nation cutting greenhouse gas emissions by 46% by 2030 and striving towards a goal of cutting 50% by 2050. These light metals contribute towards decreasing carbon emissions and energy usage. Along with this, the businesses are changing with the development of technology in metal handling, which is enhancing the quality and accuracy of the cast parts. The light metal trend is also expected to continue as major players in the industry focus on competitiveness in the global market.

To get more information on this market Request Sample

Automation and Industry 4.0 Integration

The convergence of automation and Industry 4.0 technologies is a key driver of the Japan die casting market growth, as it enables producers to make production more efficient and precise. As per an industry report, Japan industry 4.0 market is likely to reach USD 43.3 Billion by 2033, with a growth rate (CAGR) of 17.9% during 2025-2033. This fast growth reflects the growing adoption of high-tech across various industries, including die casting. Smart die casting machines, equipped with sensors, artificial intelligence (AI), and machine learning (ML), monitor in real time and offer valuable insights on performance statistics such as temperature, pressure, and material flow. This automation minimizes errors, wastage, and labor, resulting in higher efficiency in operations. In addition to this, predictive maintenance prevents equipment failure, thus greatly minimizing downtime and increasing machine life. Further, these technologies improve the overall quality and reliability of die-casting components, as well as allow producers to maintain tighter customer specifications and delivery schedules. Thus, the leading market participants are implementing such advancements to stay competitive in a growing global marketplace.

Japan Die Casting Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the country and regional levels for 2026-2034. Our report has categorized the market based on process, raw material, and application.

Process Insights:

- Pressure Die Casting

- Vacuum Die Casting

- Squeeze Die Casting

- Others

The report has provided a detailed breakup and analysis of the market based on the process. This includes pressure die casting, vacuum die casting, squeeze die casting, and others.

Raw Material Insights:

- Aluminum

- Magnesium

- Zinc

A detailed breakup and analysis of the market based on the raw material have also been provided in the report. This includes aluminum, magnesium, and zinc.

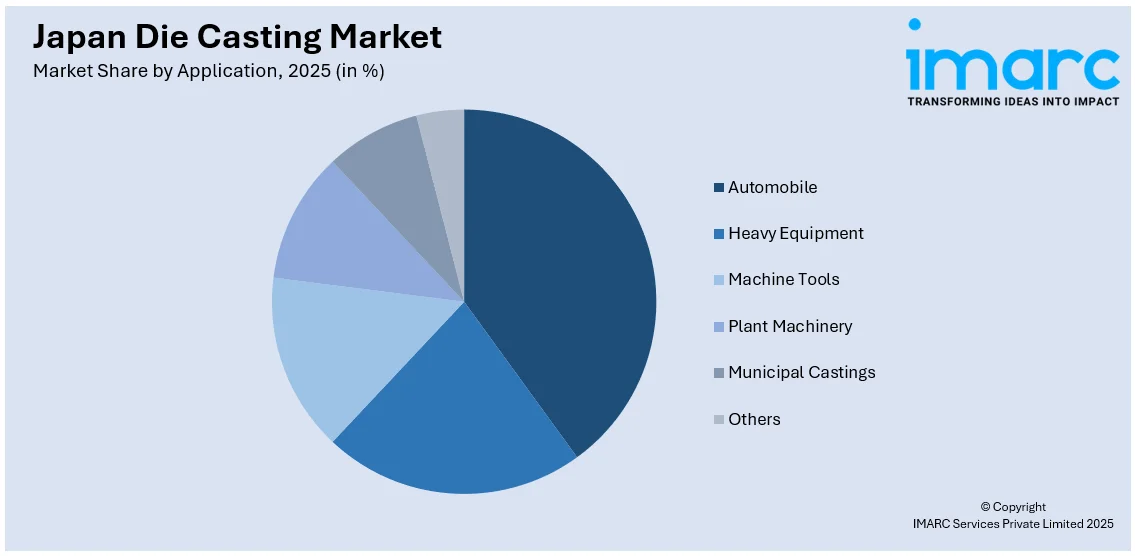

Application Insights:

Access the comprehensive market breakdown Request Sample

- Automobile

- Body Parts

- Engine Parts

- Transmission Parts

- Others

- Heavy Equipment

- Construction

- Farming

- Mining

- Machine Tools

- Plant Machinery

- Chemical Plants

- Petroleum Plants

- Thermal Plants

- Paper

- Textile

- Others

- Municipal Castings

- Valves and Fittings and Pipes

- Others

The report has provided a detailed breakup and analysis of the market based on the application. This includes automobile (body parts, engine parts, transmission parts, and others), heavy equipment (construction, farming, and mining), machine tools, plant machinery (chemical plants, petroleum plants, thermal plants, paper, textile, and others), municipal castings (valves and fittings and pipes), and others.

Regional Insights:

- Kanto Region

- Kansai/Kinki Region

- Central/ Chubu Region

- Kyushu-Okinawa Region

- Tohoku Region

- Chugoku Region

- Hokkaido Region

- Shikoku Region

The report has also provided a comprehensive analysis of all the major regional markets, which include Kanto Region, Kansai/Kinki Region, Central/ Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, and Shikoku Region.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

Japan Die Casting Market News:

- On August 20, 2024, UBE Machinery Corporation, Ltd. revealed the creation and release of the UH9000, a die casting machine with an ultra-large 9,000-metric-ton clamping force—the largest ever supplied domestically in Japan. In its giga casting application, the UH9000 makes it possible to mold large aluminum body structure parts for battery electric vehicles (BEVs) integrally, greatly minimizing the number of parts and manufacturing processes.

- On September 18, 2024, Hitachi Industrial Products, Ltd. announced the commercialization of the world's first copper die-cast rotor for railway traction motors. The innovation slashes rotor weight by around 15 kg versus conventional copper bar types, improving energy efficiency and assisting with carbon neutrality in rail operations.

Japan Die Casting Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2025 |

| Historical Period | 2020-2025 |

| Forecast Period | 2026-2034 |

| Units | Billion USD |

| Scope of the Report |

Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Processes Covered | Pressure Die Casting, Vacuum Die Casting, Squeeze Die Casting, Others |

| Raw Materials Covered | Aluminum, Magnesium, Zinc |

| Applications Covered |

|

| Regions Covered | Kanto Region, Kansai/Kinki Region, Central/ Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, Shikoku Region |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the Japan die casting market performed so far and how will it perform in the coming years?

- What is the breakup of the Japan die casting market on the basis of process?

- What is the breakup of the Japan die casting market on the basis of raw material?

- What is the breakup of the Japan die casting market on the basis of application?

- What is the breakup of the Japan die casting market on the basis of region?

- What are the various stages in the value chain of the Japan die casting market?

- What are the key driving factors and challenges in the Japan die casting market?

- What is the structure of the Japan die casting market and who are the key players?

- What is the degree of competition in the Japan die casting market?

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the Japan die casting market from 2020-2034.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the Japan die casting market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the Japan die casting industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)