Japan Electric Welding Equipment Market Size, Share, Trends and Forecast by Equipment, Technology, Application, and Region, 2026-2034

Japan Electric Welding Equipment Market Overview:

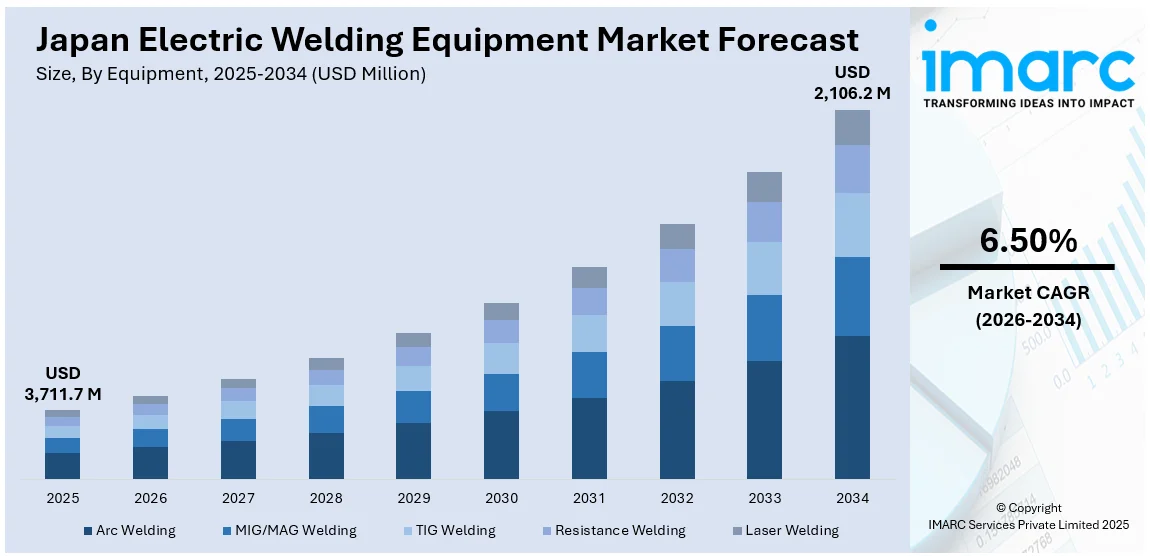

The Japan Electric Welding Equipment Market size reached USD 2,106.2 Million in 2025. Looking forward, IMARC Group expects the market to reach USD 3,711.7 Million by 2034, exhibiting a growth rate (CAGR) of 6.50% during 2026-2034. The market is propelled by rising automation in manufacturing, particularly in automotive and aerospace sectors requiring high precision. Advancements in energy-efficient and eco-friendly technologies, such as inverter-based systems, support sustainability goals. Additionally, the growing integration of smart connectivity and Internet of Things (IoT) features enables real-time monitoring and optimization, boosting productivity and quality control are some of the key factors supporting the Japan electric welding equipment market share.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2025

|

|

Forecast Years

|

2026-2034

|

|

Historical Years

|

2020-2025

|

| Market Size in 2025 | USD 2,106.2 Million |

| Market Forecast in 2034 | USD 3,711.7 Million |

| Market Growth Rate 2026-2034 | 6.50% |

Japan Electric Welding Equipment Market Trends:

Advancements in Automation and Robotics Integration

Japanese market for electric welding equipment is being increasingly driven toward automation and robots to improve efficiency in manufacturing. Robotic arms and artificial intelligence (AI) based systems are transforming welding techniques in industries, such as automotive and electronics. The automated systems bring uniform quality, enhance safety levels, and are cost-effective because they eliminate expensive labor costs as they automate tough welding operations. Moreover, adaptive welding technologies, which can set themselves up on various materials and configurations, are becoming popular. This transition not only increases the speed of production but also reduces errors and thus is best suited to high-precision manufacturing. Top manufacturers are ongoing investments in research and development (R&D) to come up with advanced automated welding solutions to stay competitive in the market.

To get more information on this market Request Sample

Shift Towards Energy-Efficient and Eco-Friendly Equipment

With Japan's emphasis on sustainability, there is also an increasing call for energy-saving and environmentally friendly welding machines. According to the reports, the government endorses this development through programs, such as the Top Runner Program to lower power waste by 35% over typical standards. This is especially appropriate for welding equipment, where makers are embracing inverters-based devices that provide increased energy efficiency, less power intake, and cleaner emissions. Furthermore, these devices are appealing in view of Japan's target for carbon neutrality. Besides, manufacturers of welding equipment have begun to adopt more recyclable materials and better-designed equipment aimed at reducing wastage during the manufacturing process. The trend has been influenced both by government standards and consumer desire for eco-friendly products. Therefore, energy-efficient welding equipment has become the new normal in a wide range of industries, propelling Japan electric welding equipment market growth toward its environmental protection and sustainability campaign.

Customization and Smart Connectivity Features

The Japanese market for electric welding equipment is seeing increased customization and smart connectivity. The manufacturers are providing more customized welding solutions to suit the individual requirements of industries such as aerospace, automotive, and shipbuilding. Moreover, welding equipment is now more and more being equipped with smart connectivity options that support remote monitoring and diagnostics. With Internet of Things (IoT) connectivity, operators are able to monitor performance metrics, weld parameters, and receive real-time maintenance notifications. This connection enhances efficiency, minimizes downtime, and preserves high-quality standards. All these technologies are revolutionizing the management of welding operations with greater control and reliability for manufacturers.

Japan Electric Welding Equipment Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the country and regional level for 2026-2034. Our report has categorized the market based on equipment, technology, and application.

Equipment Insights:

- Arc Welding

- MIG/MAG Welding

- TIG Welding

- Resistance Welding

- Laser Welding

The report has provided a detailed breakup and analysis of the market based on the equipment. This includes Arc welding, MIG/MAG welding, TIG welding, resistance welding, and laser welding.

Technology Insights:

- Conventional Welding

- Automated Welding

- Robotic Welding

A detailed breakup and analysis of the market based on the technology have also been provided in the report. This includes conventional welding, automated welding, and robotic welding.

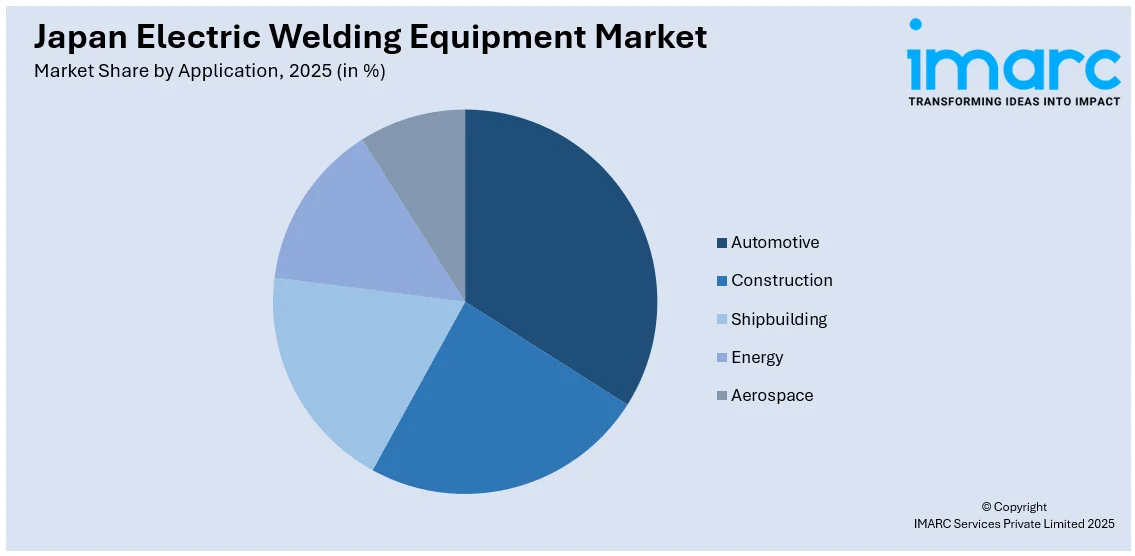

Application Insights:

Access the comprehensive market breakdown Request Sample

- Automotive

- Construction

- Shipbuilding

- Energy

- Aerospace

The report has provided a detailed breakup and analysis of the market based on the application. This includes automotive, construction, shipbuilding, energy, and aerospace.

Regional Insights:

- Kanto Region

- Kansai/Kinki Region

- Central/ Chubu Region

- Kyushu-Okinawa Region

- Tohoku Region

- Chugoku Region

- Hokkaido Region

- Shikoku Region

The report has also provided a comprehensive analysis of all the major regional markets, which include Kanto, Kansai/Kinki, Central/ Chubu, Kyushu-Okinawa, Tohoku, Chugoku, Hokkaido, and Shikoku Region.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

Japan Electric Welding Equipment Market News:

- In April 2025, Techman Robot partnered with Panasonic Connect's Welding Systems Division to increase welding automation in Japan. The collaboration combines Techman Robot's collaborative robots with Panasonic's digital welding machines, introducing the "Welding Node" module for easier setup. This solution addresses labor shortages by simplifying automation and enhancing welding processes with AI and vision systems. The partnership, established in 2023, aims to accelerate automation and expand applications in the Japanese market.

- In February 2025, Japan initiated the JT-60SA, the world's dominant experimental nuclear fusion reactor, a major milestone in the pursuit of fusion energy. A joint effort between Japan and the EU, the JT-60SA will assist the International Thermonuclear Experimental Reactor (ITER) project in France. The reactor employs a "tokamak" vessel to confine plasma at 200 million degrees Celsius, aiming to mimic the sun's fusion process to produce clean, limitless energy.

Japan Electric Welding Equipment Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2025 |

| Historical Period | 2020-2025 |

| Forecast Period | 2026-2034 |

| Units | Million USD |

| Scope of the Report |

Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Equipments Covered | Arc Welding, MIG/MAG Welding, TIG Welding, Resistance Welding, Laser Welding |

| Technologies Covered | Conventional Welding, Automated Welding, Robotic Welding |

| Applications Covered | Automotive, Construction, Shipbuilding, Energy, Aerospace |

| Regions Covered | Kanto Region, Kansai/Kinki Region, Central/ Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, and Shikoku Region |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the Japan electric welding equipment market performed so far and how will it perform in the coming years?

- What is the breakup of the Japan electric welding equipment market on the basis of equipment?

- What is the breakup of the Japan electric welding equipment market on the basis of technology?

- What is the breakup of the Japan electric welding equipment market on the basis of application?

- What is the breakup of the Japan electric welding equipment market on the basis of region?

- What are the various stages in the value chain of the Japan electric welding equipment market?

- What are the key driving factors and challenges in the Japan electric welding equipment market?

- What is the structure of the Japan electric welding equipment market and who are the key players?

- What is the degree of competition in the Japan electric welding equipment market?

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the Japan electric welding equipment market from 2020-2034.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the Japan electric welding equipment market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the Japan electric welding equipment industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)