Japan Ferrous Scrap Recycling Market Size, Share, Trends and Forecast by Type, Application, End User, and Region, 2026-2034

Japan Ferrous Scrap Recycling Market Overview:

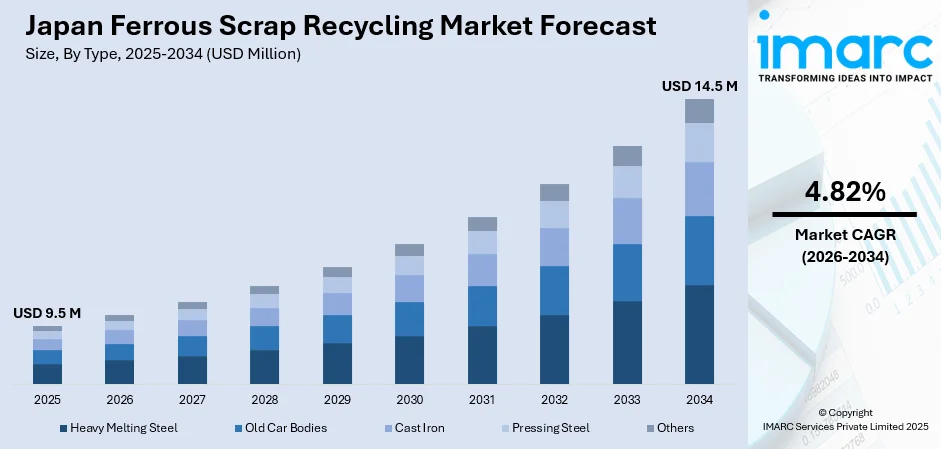

The Japan ferrous scrap recycling market size reached USD 9.5 Million in 2025. Looking forward, IMARC Group expects the market to reach USD 14.5 Million by 2034, exhibiting a growth rate (CAGR) of 4.82% during 2026-2034. The market is driven by rising steel production, tight environmental regulations, and emerging demand for eco-friendly raw materials. Further, the development of recycling infrastructure in the country, government support, and technological advancements increase the efficiency and profitability of recycling ferrous scrap. Also, expansion in construction and automobile activities and the necessity to reduce carbon emissions further augment the Japan ferrous scrap recycling market share.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2025

|

|

Forecast Years

|

2026-2034

|

|

Historical Years

|

2020-2025

|

| Market Size in 2025 | USD 9.5 Million |

| Market Forecast in 2034 | USD 14.5 Million |

| Market Growth Rate 2026-2034 | 4.82% |

Japan Ferrous Scrap Recycling Market Trends:

Technological Advancements in Scrap Sorting and Processing

The industry is undergoing rapid change due to continual technological developments in scrap processing and sorting. As materials become more complex and higher purity is required in recycled products, firms are spending on the most advanced technologies like AI sorting machines, optical sensors, and magnetic sorters. These technologies allow for accurate separation of ferrous and non-ferrous metals, minimizing contamination and maximizing the purity of the recovered metal. Robotics and automation are also incorporated into material handling and processing lines, which improves the efficiency of operations and minimizes reliance on manual intervention. Smart monitoring systems and data analytics software are also implemented to maximize scrap yard efficiency, minimize downtime, and maximize yield rates. By embracing cutting-edge technologies, recyclers are not just increasing profitability but also following stringent environmental and industrial regulations.

To get more information on this market Request Sample

Integration of Circular Economy Practices

The integration of circular economy principles is emerging as a key trend in the market, driven by both government policy and corporate sustainability goals. As part of Japan's Green Growth Strategy and Circular Economy Vision, economies are encouraged to reduce waste, recycle resources, and optimize material efficiency across product life stages. This change is encouraging steel producers and recyclers to create closed-loop systems in which end products are gathered, processed, and returned to production lines. Besides this, producers are also working cooperatively with recyclers to standardize product designs that will make it easier to dismantle and recover materials. Additionally, environmental product declarations (EPDs) and life cycle assessments (LCAs) are becoming increasingly important means of measuring and communicating the value of recycled steel content, particularly in the automotive and construction industries. By aligning business operations with circular economy models, market players are reducing environmental impact and strengthening supply chain resilience, thereby meeting evolving consumer and regulatory expectations.

Increasing Demand from the Construction Sector

The growing demand from the construction sector is emerging as a significant factor propelling the Japan ferrous scrap recycling market growth. According to industry reports, the construction market in Japan is expected to reach USD 937.4 Billion by 2033, exhibiting a growth rate (CAGR) of 4.37% during 2025-2033. This growth is driven by the ongoing urban redevelopment projects, climate-resilient infrastructure upgrades, and public works initiatives under the National Resilience Plan. These infrastructure developments are creating a sustained demand for steel and, consequently, ferrous scrap as a raw material. Recycled materials are increasingly favored in construction due to their cost-effectiveness, lower carbon footprint, and alignment with green building standards. Construction companies are incorporating recycled materials into structural components, reinforcing bars, and beams to meet environmental targets and secure government certifications. As the sector emphasizes sustainable procurement, the integration of high-quality steel is becoming a strategic priority, reinforcing the value of recycled ferrous scrap in construction supply chains.

Japan Ferrous Scrap Recycling Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the country and regional levels for 2026-2034. Our report has categorized the market based on type, application, and end user.

Type Insights:

- Heavy Melting Steel

- Old Car Bodies

- Cast Iron

- Pressing Steel

- Others

The report has provided a detailed breakup and analysis of the market based on the type. This includes heavy melting steel, old car bodies, cast iron, pressing steel, and others.

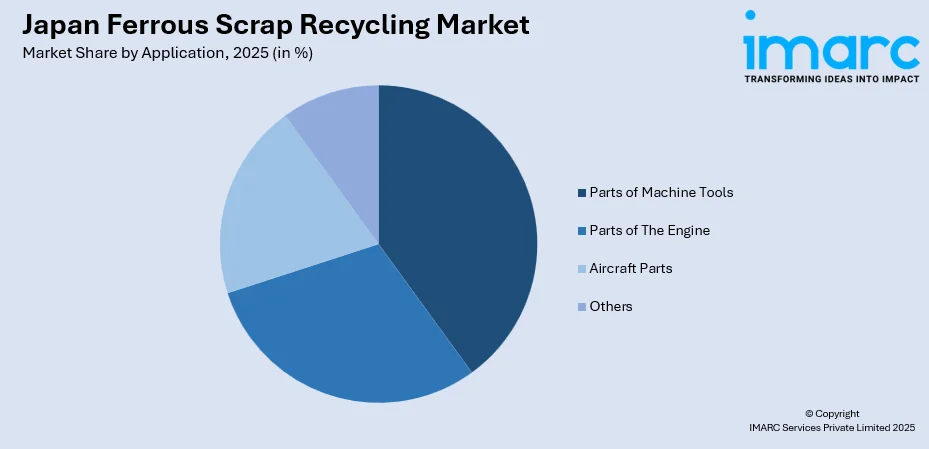

Application Insights:

Access the comprehensive market breakdown Request Sample

- Parts of Machine Tools

- Parts of The Engine

- Aircraft Parts

- Others

A detailed breakup and analysis of the market based on the application have also been provided in the report. This includes parts of machine tools, parts of the engine, aircraft parts, and others.

End User Insights:

- Construction

- Automotive

- Shipbuilding

- Equipment Manufacturing

- Consumer Appliances

- Others

The report has provided a detailed breakup and analysis of the market based on the end user. This includes construction, automotive, shipbuilding, equipment manufacturing, consumer appliances, and others.

Regional Insights:

- Kanto Region

- Kansai/Kinki Region

- Central/ Chubu Region

- Kyushu-Okinawa Region

- Tohoku Region

- Chugoku Region

- Hokkaido Region

- Shikoku Region

The report has also provided a comprehensive analysis of all the major regional markets, which include Kanto Region, Kansai/Kinki Region, Central/ Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, and Shikoku Region.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

Japan Ferrous Scrap Recycling Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2025 |

| Historical Period | 2020-2025 |

| Forecast Period | 2026-2034 |

| Units | Million USD |

| Scope of the Report |

Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Types Covered | Heavy Melting Steel, Old Car Bodies, Cast Iron, Pressing Steel, Others |

| Applications Covered | Parts of Machine Tools, Parts of The Engine, Aircraft Parts, Others |

| End Users Covered | Construction, Automotive, Shipbuilding, Equipment Manufacturing, Consumer Appliances, Others |

| Regions Covered | Kanto Region, Kansai/Kinki Region, Central/ Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, Shikoku Region |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the Japan ferrous scrap recycling market performed so far and how will it perform in the coming years?

- What is the breakup of the Japan ferrous scrap recycling market on the basis of type?

- What is the breakup of the Japan ferrous scrap recycling market on the basis of application?

- What is the breakup of the Japan ferrous scrap recycling market on the basis of end user?

- What is the breakup of the Japan ferrous scrap recycling market on the basis of region?

- What are the various stages in the value chain of the Japan ferrous scrap recycling market?

- What are the key driving factors and challenges in the Japan ferrous scrap recycling market?

- What is the structure of the Japan ferrous scrap recycling market and who are the key players?

- What is the degree of competition in the Japan ferrous scrap recycling market?

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the Japan ferrous scrap recycling market from 2020-2034.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the Japan ferrous scrap recycling market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the Japan ferrous scrap recycling industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)