Japan Foundry and Casting Market Size, Share, Trends and Forecast by Casting Type, Manufacturing Process, End Use Industry, and Region, 2026-2034

Japan Foundry and Casting Market Overview:

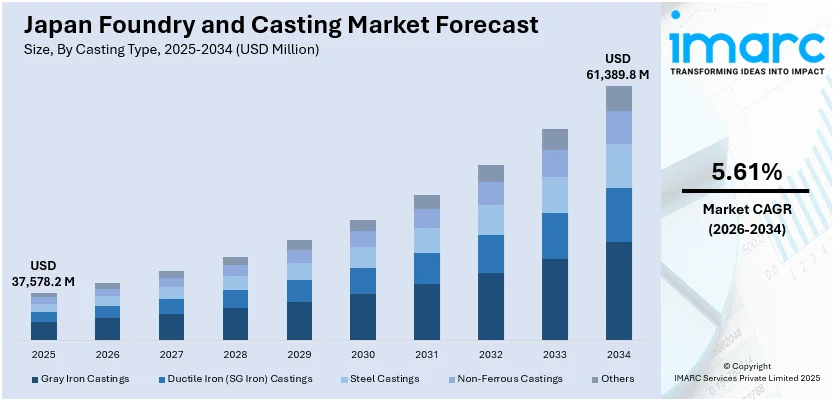

The Japan foundry and casting market size reached USD 37,578.2 Million in 2025. Looking forward, IMARC Group expects the market to reach USD 61,389.8 Million by 2034, exhibiting a growth rate (CAGR) of 5.61% during 2026-2034. Automotive and industrial machinery demand, precision engineering growth, advancements in casting technology, increasing electric vehicle production, and the need for lightweight metal components are some of the factors contributing to Japan foundry and casting market share. Environmental regulations also push innovation in eco-friendly casting processes and material recycling.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2025

|

|

Forecast Years

|

2026-2034

|

|

Historical Years

|

2020-2025

|

|

Market Size in 2025

|

USD 37,578.2 Million |

|

Market Forecast in 2034

|

USD 61,389.8 Million |

| Market Growth Rate 2026-2034 | 5.61% |

Japan Foundry and Casting Market Trends:

Growing Focus on International Collaboration and Precision Casting

Japan’s foundry and casting sector is increasingly engaging with global platforms to adopt advanced technologies and expand its market reach. Participation in large-scale international exhibitions reflects a strategic shift toward forging cross-border partnerships and staying competitive in high-precision manufacturing. Emphasis is being placed on showcasing solutions designed for automotive and industrial applications, highlighting the country’s commitment to quality, customization, and technological innovation. These engagements not only strengthen Japan’s export potential but also bring in knowledge exchange that supports efficiency and product development. The interest in such forums underlines the sector’s ambition to integrate global advancements and align with evolving production standards across key end-use segments, particularly in transportation and engineering. These factors are intensifying the Japan foundry and casting market growth. For example, in December 2024, the 10th ALUCAST EXPO, India’s largest die casting industry platform, was held from December 5-7 at Yashobhoomi, Delhi. With 200+ exhibitors and 300+ brands from countries including Japan, the event showcased cutting-edge die casting technologies and drew over 8,000 visitors from 20+ nations. Japanese firms participated in exploring collaboration opportunities and displayed precision casting solutions tailored for automotive and industrial applications.

To get more information on this market Request Sample

Emphasis on Technological Modernization in Die Casting

The foundry and casting market in Japan is witnessing a clear shift toward technological modernization, driven by the demand for high-performance components in sectors like automotive, electronics, and machinery. Participation in international exhibitions dedicated to die casting underscores the industry’s intent to benchmark against global manufacturing standards and adopt innovations in materials, tooling, and automation. Japanese manufacturers are increasingly exploring new alloys, simulation tools, and energy-efficient processes to meet the dual objectives of precision and sustainability. These platforms offer exposure to cutting-edge solutions and enable manufacturers to evaluate competitive offerings, leading to product refinement and operational improvements. The growing focus on lightweight yet durable components is influencing the adoption of next-generation casting techniques, with firms aiming to reduce defects, cycle times, and energy consumption. This modernization drive is not just about keeping pace, it’s about reinforcing Japan’s position as a leader in quality casting solutions while addressing cost pressures and evolving customer requirements across global industrial supply chains.

Japan Foundry and Casting Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the region/country level for 2026-2034. Our report has categorized the market based on casting type, manufacturing process, and end use industry.

Casting Type Insights:

- Gray Iron Castings

- Ductile Iron (SG Iron) Castings

- Steel Castings

- Non-Ferrous Castings

- Others

The report has provided a detailed breakup and analysis of the market based on the casting type. This includes gray iron castings, ductile iron (SG Iron) castings, steel castings, non-ferrous castings, and others.

Manufacturing Process Insights:

- Sand Casting

- Investment Casting

- Die Casting

- Centrifugal Casting

- Others

A detailed breakup and analysis of the market based on the manufacturing process have also been provided in the report. This includes sand casting, investment casting, die casting, centrifugal casting, and others.

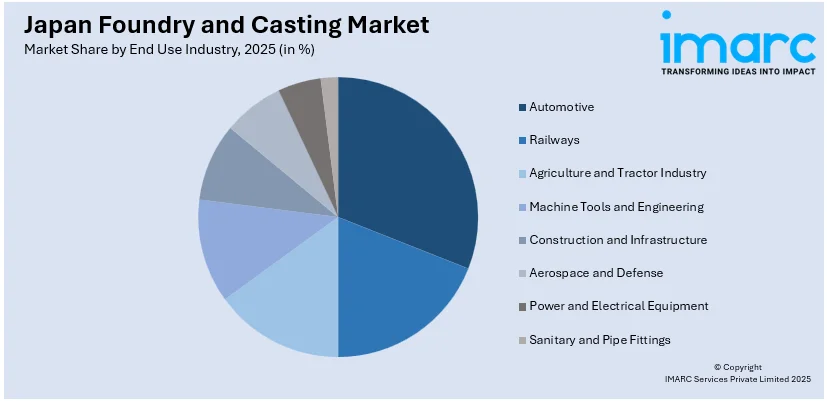

End Use Industry Insights:

Access the comprehensive market breakdown Request Sample

- Automotive

- Railways

- Agriculture and Tractor Industry

- Machine Tools and Engineering

- Construction and Infrastructure

- Aerospace and Defense

- Power and Electrical Equipment

- Sanitary and Pipe Fittings

A detailed breakup and analysis of the market based on the end use industry have also been provided in the report. This includes automotive, railways, agriculture and tractor industry, machine tools and engineering, construction and infrastructure, aerospace and defense, power and electrical equipment, and sanitary and pipe fittings.

Regional Insights:

- Kanto Region

- Kansai/Kinki Region

- Central/Chubu Region

- Kyushu-Okinawa Region

- Tohoku Region

- Chugoku Region

- Hokkaido Region

- Shikoku Region

The report has also provided a comprehensive analysis of all the major regional markets, which include Kanto Region, Kansai/Kinki Region, Central/Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, and Shikoku Region.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

Japan Foundry and Casting Market News:

- In January 2025, VRX Silica signed non-binding offtake agreements to supply 440,000 tons of certified foundry sand annually, including with Japan’s Yamakawa Sangyo Co. Ltd. The deal supports Japan's foundry sector, which services key automotive and marine industries, highlighting growing demand for high-quality silica sand in the region.

Japan Foundry and Casting Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2025 |

| Historical Period | 2020-2025 |

| Forecast Period | 2026-2034 |

| Units | Million USD |

| Scope of the Report |

Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Casting Types Covered | Gray Iron Castings, Ductile Iron (SG Iron) Castings, Steel Castings, Non-Ferrous Castings, Others |

| Manufacturing Processes Covered | Sand Casting, Investment Casting, Die Casting, Centrifugal Casting, Others |

| End Use Industries Covered | Automotive, Railways, Agriculture and Tractor Industry, Machine Tools and Engineering, Construction and Infrastructure, Aerospace and Defense, Power and Electrical Equipment, Sanitary and Pipe Fittings |

| Regions Covered | Kanto Region, Kansai/Kinki Region, Central/Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, Shikoku Region |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the Japan foundry and casting market performed so far and how will it perform in the coming years?

- What is the breakup of the Japan foundry and casting market on the basis of casting type?

- What is the breakup of the Japan foundry and casting market on the basis of manufacturing process?

- What is the breakup of the Japan foundry and casting market on the basis of end use industry?

- What is the breakup of the Japan foundry and casting market on the basis of region?

- What are the various stages in the value chain of the Japan foundry and casting market?

- What are the key driving factors and challenges in the Japan foundry and casting market?

- What is the structure of the Japan foundry and casting market and who are the key players?

- What is the degree of competition in the Japan foundry and casting market?

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the Japan foundry and casting market from 2020-2034.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the Japan foundry and casting market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the Japan foundry and casting industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)