Japan Galvanization Market Size, Share, Trends and Forecast by Type, Combustion Chamber Type, Application, End Use Industry, and Region, 2026-2034

Japan Galvanization Market Overview:

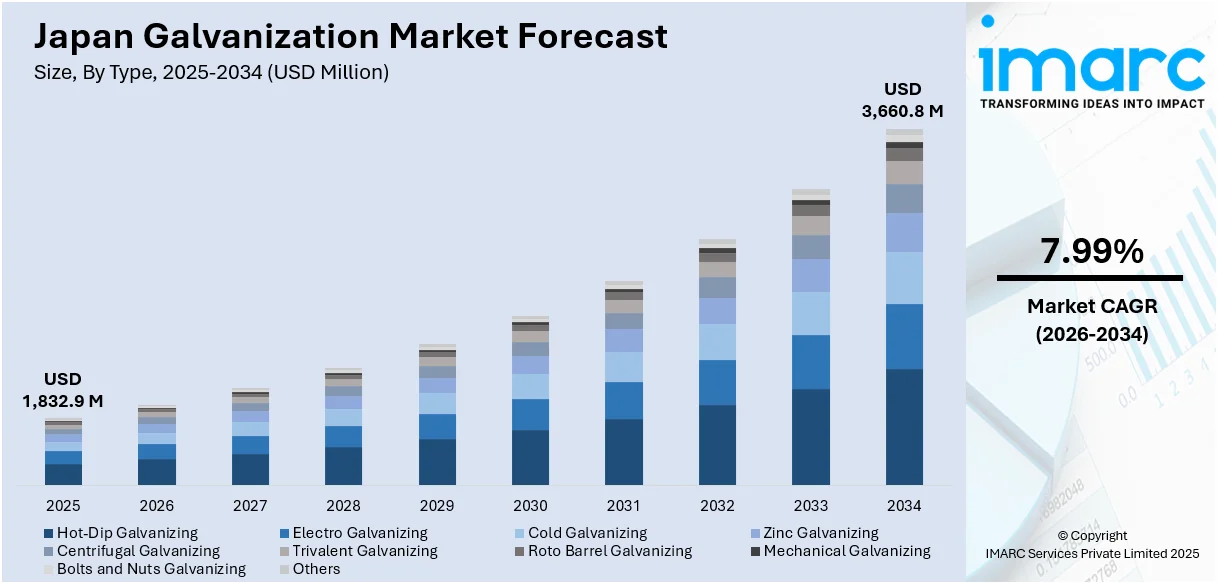

The Japan galvanization market size reached USD 1,832.9 Million in 2025. Looking forward, IMARC Group expects the market to reach USD 3,660.8 Million by 2034, exhibiting a growth rate (CAGR) of 7.99% during 2026-2034. The market is growing, fueled by the growing demand for corrosion-resistant products in different industries, especially construction, automotive, and energy. With advancements in green technology and increasing emphasis on sustainability, the Japan galvanization market share is expanding rapidly.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2025

|

|

Forecast Years

|

2026-2034

|

|

Historical Years

|

2020-2025

|

| Market Size in 2025 | USD 1,832.9 Million |

| Market Forecast in 2034 | USD 3,660.8 Million |

| Market Growth Rate 2026-2034 | 7.99% |

Japan Galvanization Market Trends:

Growing Demand in Building and Automotive Industries

Japan's galvanization industry is dominated by the increased demand for corrosion-resistant products in the building and motor vehicle industries. As Japanese industries emphasize durability and environmental friendliness, there has been an increased demand for galvanized steel. Galvanized steel is also used in the building sector because it is resistant to harsh weather conditions. Thus, it is the best material for constructing infrastructure such as bridges, roads, and buildings. In the automotive industry, companies nowadays prefer the use of galvanized steel for automobile body panels because it is stronger and more resistant to corrosion and rust. The trend has also been promoted by Japan's emphasis on increasing sustainability and decreasing carbon footprints. Consequently, the nation has more environmentally friendly processes in place, such as using more long-term galvanization technology that provides durable and recyclable material. Also, the growth of Japan's galvanization markets has been supported by the move in the auto industry toward electric vehicles, in which galvanized steel is pivotal in providing structural integrity and light weights. The continued investments in the process of modernizing production methods and increasing infrastructure in Japan will continue to drive demand in these sectors. This transformation in manufacturing methodologies will play a major role in the long-term development of Japan's galvanization market.

To get more information on this market Request Sample

Green Technologies Leading Market Innovation

A significant driver of Japan's galvanization market is the growing emphasis on green technologies and sustainability. The Japanese government's commitment to decarbonizing its economy has spurred investments in low-emission technologies, including green steel production. These advancements in eco-friendly steel production techniques are closely linked to the galvanization industry, as galvanized materials are increasingly favored for their durability and recyclability. The government of Japan has implemented policies and subsidies to encourage low-carbon steel manufacturing, thereby having a direct influence on the demand for galvanized products. Apart from the green steel program, the increased use of renewable energy schemes like solar and wind farms has also fueled the demand for galvanized materials. The corrosion resistance and durability provided by galvanized steel make it a critical element in the building of renewable energy structures, such as wind turbine towers and solar panel support systems. The application of galvanization in these green initiatives is likely to push innovation in coating technologies, enhancing the performance and efficiency of galvanized steel in such applications. Consequently, Japan's galvanization market growth is being driven by the demand for sustainable energy and infrastructure development. This emphasis on sustainability, along with technological improvement in galvanization, will continue to drive long-term Japan galvanization market growth.

Japan Galvanization Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the country and regional level for 2026-2034. Our report has categorized the market based on type, combustion chamber type, application, and end use industry.

Type Insights:

- Hot-Dip Galvanizing

- Electro Galvanizing

- Cold Galvanizing

- Zinc Galvanizing

- Centrifugal Galvanizing

- Trivalent Galvanizing

- Roto Barrel Galvanizing

- Mechanical Galvanizing

- Bolts and Nuts Galvanizing

- Others

The report has provided a detailed breakup and analysis of the market based on the type. This includes hot-tip galvanizing, electro galvanizing, cold galvanizing, zinc galvanizing, centrifugal galvanizing, trivalent galvanizing, roto barrel galvanizing, mechanical galvanizing, bolts and nuts galvanizing, and others.

Combustion Chamber Type Insights:

- Oil

- Gas

- Electric

- Others

A detailed breakup and analysis of the market based on the combustion chamber type have also been provided in the report. This includes oil, gas, electric, and others.

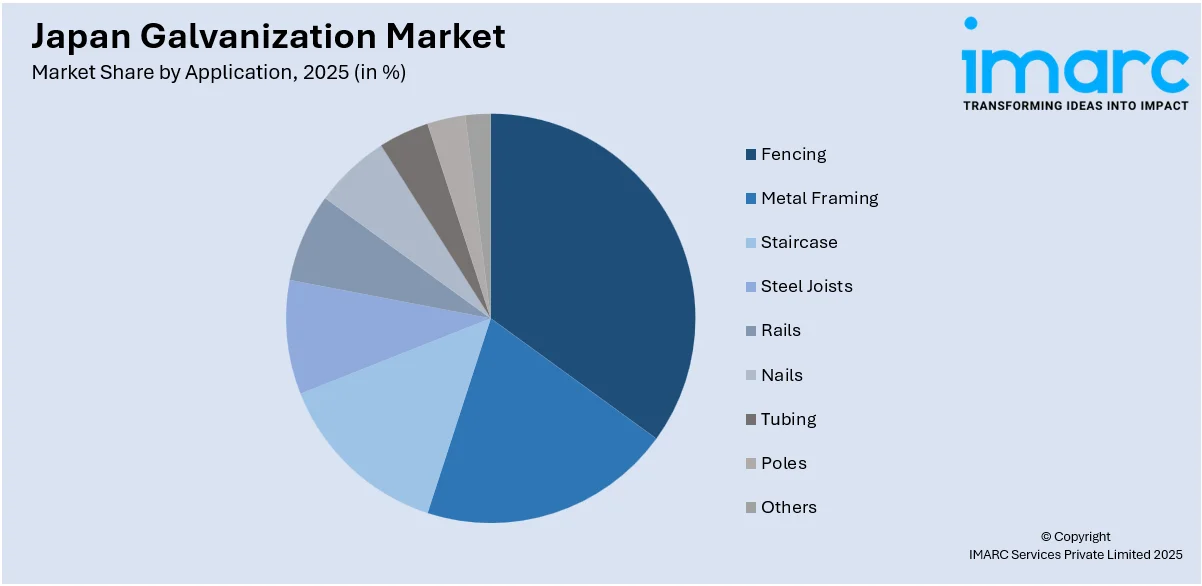

Application Insights:

Access the comprehensive market breakdown Request Sample

- Fencing

- Metal Framing

- Staircase

- Steel Joists

- Rails

- Nails

- Tubing

- Poles

- Others

A detailed breakup and analysis of the market based on the application have also been provided in the report. This includes fencing, metal framing, staircase, steel joints, rails, nails, tubing, poles, and others.

End Use Industry Insights:

- Electrical and Electronics

- Wind and Solar Industries

- Energy Industry

- Telecommunications Industry

- Transportation

- Aerospace

- Marine

- Automotive

- Others

- Building and Construction

- Residential Construction

- Commercial Construction

- Industrial

- Infrastructure

- Others

A detailed breakup and analysis of the market based on the end use industry have also been provided in the report. This includes electrical and electronics, wind and solar industries, energy industry, telecommunications industry, transportation (aerospace, marine, automotive, and others), building and construction (residential construction, commercial construction, industrial, and infrastructure), and others.

Regional Insights:

- Kanto Region

- Kansai/Kinki Region

- Central/ Chubu Region

- Kyushu-Okinawa Region

- Tohoku Region

- Chugoku Region

- Hokkaido Region

- Shikoku Region

The report has also provided a comprehensive analysis of all the major regional markets, which include Kanto Region, Kansai/Kinki Region, Central/ Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, and Shikoku Region.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

Japan Galvanization Market News:

- February 2025: Japan launched a 50,000 yen subsidy for clean energy vehicles (CEVs) made from low-carbon emission steel, boosting the demand for galvanized materials. This initiative is expected to drive growth in Japan's galvanization market by encouraging green steel production and adoption in the automotive sector.

Japan Galvanization Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2025 |

| Historical Period | 2020-2025 |

| Forecast Period | 2026-2034 |

| Units | Million USD |

| Scope of the Report |

Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Types Covered | Hot-Dip Galvanizing, Electro Galvanizing, Cold Galvanizing, Zinc Galvanizing, Centrifugal Galvanizing, Trivalent Galvanizing, Roto Barrel Galvanizing, Mechanical Galvanizing, Bolts and Nuts Galvanizing, Others |

| Combustion Chamber Types Covered | Oil, Gas, Electric, Others |

| Applications Covered | Fencing, Metal Framing, Staircase, Steel Joists, Rails, Nails, Tubing, Poles, Others |

| Distribution Channels Covered |

|

| Regions Covered | Kanto Region, Kansai/Kinki Region, Central/ Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, Shikoku Region |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the Japan galvanization market performed so far and how will it perform in the coming years?

- What is the breakup of the Japan galvanization market on the basis of type?

- What is the breakup of the Japan galvanization market on the basis of combustion chamber type?

- What is the breakup of the Japan galvanization market on the basis of application?

- What is the breakup of the Japan galvanization market on the basis of end use industry?

- What is the breakup of the Japan galvanization market on the basis of region?

- What are the various stages in the value chain of the Japan galvanization market?

- What are the key driving factors and challenges in the Japan galvanization market?

- What is the structure of the Japan galvanization market and who are the key players?

- What is the degree of competition in the Japan galvanization market?

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the Japan galvanization market from 2020-2034.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the Japan galvanization market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the Japan galvanization industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)