Japan Heat Exchanger Tubes Market Size, Share, Trends and Forecast by Material Type, Product Type, Tube Configuration, Distribution Channel, End Use Industry, and Region, 2026-2034

Japan Heat Exchanger Tubes Market Overview:

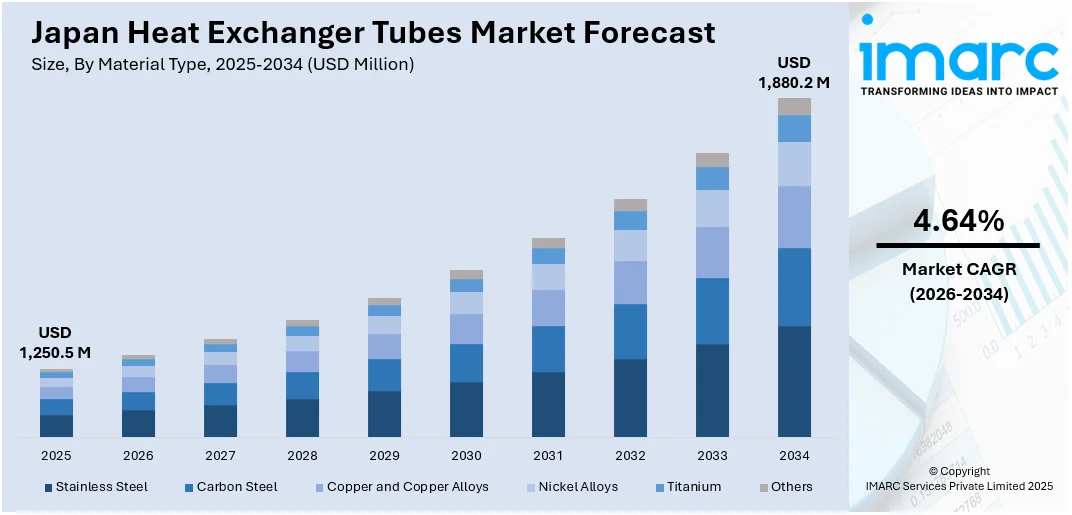

The Japan heat exchanger tubes market size reached USD 1,250.5 Million in 2025. Looking forward, IMARC Group expects the market to reach USD 1,880.2 Million by 2034, exhibiting a growth rate (CAGR) of 4.64% during 2026-2034. Increased industrialization, energy-efficient technology demand, and sustainability issues are drivers propelling the market growth. Moreover, materials technology development, rising energy costs, environmental legislation, and heat transfer technology improvements are propelling the market growth. Additionally, market growth is being driven by the expansion of power generation, the rise in automotive production, upgrades in industrial manufacturing infrastructure, and the integration of renewable energy sources. Apart from this, the need for cost-effective operations and the necessity of efficient cooling systems in electronics are collectively propelling the Japan heat exchanger tubes market share.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2025

|

|

Forecast Years

|

2026-2034

|

|

Historical Years

|

2020-2025

|

| Market Size in 2025 | USD 1,250.5 Million |

| Market Forecast in 2034 | USD 1,880.2 Million |

| Market Growth Rate 2026-2034 | 4.64% |

Japan Heat Exchanger Tubes Market Trends:

Increasing Industrialization and Requirement for Energy-Efficient Products

Accelerated industrialization in Japan has contributed to growing demand for heat exchanger tubes in power generation and manufacturing industries. Efficient use of energy is particularly required with industries reducing operating costs and meeting energy-saving targets. Heat exchangers play a big role in energy efficiency as they facilitate enhanced heat transfer between fluids, which in turn contributes to reduced energy consumption. As per a report presented by the International Energy Agency (IEA), Japan is keen on improving energy efficiency in industry so that it increases energy intensity by 30% by 2030. This has motivated Japanese industry to adopt heat exchanger technology as part of its broader strategy of saving energy. By making industrial processes more efficient and reducing energy consumption, heat exchangers help companies attain sustainability goals in an economical way. In line with this, the focus of the Japanese government on stimulating energy-saving technologies in the manufacturing industry further contributes to the demand for advanced heat exchanger systems, further driving the development of the Japan heat exchanger tubes market growth.

To get more information on this market Request Sample

Focus on Sustainability and Green Manufacturing Practices

Sustainability is fast emerging as a top priority among Japanese businesses, and businesses are seeking to minimize their carbon footprint through energy-saving technology, including heat exchanger systems. Heat exchangers are not just energy savers but also help in minimizing the release of carbon, making them indispensable in the process of green manufacturing. This sustainability push is linked to the need for heat exchangers that enable businesses to recover and reuse energy, thereby reducing overall energy consumption and emissions. In February 2024, Daikin Industries, a leading Japanese HVAC manufacturer, unveiled a new line of high-efficiency heat exchangers aimed at reducing industrial carbon emissions, as part of Japan’s broader strategy to achieve carbon neutrality by 2050. Japanese manufacturers are embracing advanced heat exchanger technology to meet environmental benchmarks and comply with tightened environmental regulations, as reported by a Japan External Trade Organization (JETRO) report. For example, the use of corrosion-resistant alloys in heat exchanger tubes not only extends the lifetime of the systems but also reduces maintenance costs as well as ensures more sustainable operations.

Technological Developments in Materials and Durability

Developments in design and material technology have significantly enhanced the performance and lifespan of heat exchangers in Japan's industrial manufacturing sector. With the need for enhanced efficiency and lifespan of heat exchanger tubes, firms have increasingly applied state-of-the-art materials that enhance heat transfer and wear life. Corrosion-resistant material and composite material have emerged as a central element in the creation of long-lasting heat exchangers that can push through difficult conditions in petrochemical refining and power generation sectors. Recent research in corrosion-resistant material has helped reduce maintenance requirements and extend the life cycle of heat exchangers, in turn reducing companies' operating costs. These materials not only make the equipment more efficient but also ensure the reliability of heat exchangers under high-temperature and high-pressure applications. Additionally, Japan has seen the use of smart technology for heat exchangers to enable real-time monitoring and optimization of performance. The combination of advanced materials and smart technology is making heat exchangers economical, efficient, and reliable, which is paving the way for their use across numerous industries.

Japan Heat Exchanger Tubes Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the country and regional level for 2026-2034. Our report has categorized the market based on material type, product type, tube configuration, distribution channel, and end use industry.

Material Type Insights:

- Stainless Steel

- Carbon Steel

- Copper and Copper Alloys

- Nickel Alloys

- Titanium

- Others

The report has provided a detailed breakup and analysis of the market based on the material type. This includes stainless steel, carbon steel, copper and copper alloys, nickel alloys, titanium, and others.

Product Type Insights:

- Seamless Heat Exchanger Tubes

- Welded Heat Exchanger Tubes

A detailed breakup and analysis of the market based on the product type have also been provided in the report. This includes seamless heat exchanger tubes and welded heat exchanger tubes.

Tube Configuration Insights:

- U-Tubes

- Straight Tubes

- Finned Tubes

The report has provided a detailed breakup and analysis of the market based on the tube configuration. This includes U-tubes, straight tubes, and finned tubes.

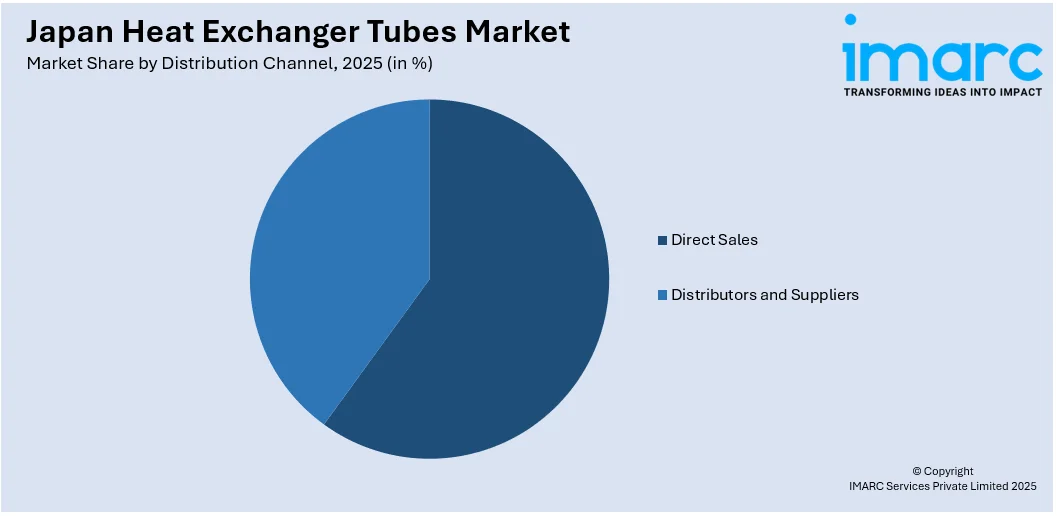

Distribution Channel Insights:

Access the comprehensive market breakdown Request Sample

- Direct Sales

- Distributors and Suppliers

A detailed breakup and analysis of the market based on the distribution channel have also been provided in the report. This includes direct sales and distributors and suppliers.

End-Use Industry Insights:

- Power Generation

- Oil and Gas

- Chemical and Petrochemical

- HVAC and Refrigeration

- Food and Beverage Processing

- Automotive and Aerospace

- Marine and Shipbuilding

- Pharmaceuticals

- Others

The report has provided a detailed breakup and analysis of the market based on the end-use industry. This includes power generation, oil and gas, chemical and petrochemical, HVAC and refrigeration, food and beverage processing, automotive and aerospace, marine and shipbuilding, pharmaceuticals, and others.

Regional Insights:

- Kanto Region

- Kansai/Kinki Region

- Central/Chubu Region

- Kyushu-Okinawa Region

- Tohoku Region

- Chugoku Region

- Hokkaido Region

- Shikoku Region

The report has also provided a comprehensive analysis of all the major regional markets, which include the Kanto Region, Kansai/Kinki Region, Central/Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, and Shikoku Region.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

Japan Heat Exchanger Tubes Market News:

- In 2023, Seibu Giken unveiled the HI-PANEX-ION®, the world's first ion adsorption total heat exchanger, designed to prevent odor migration and reduce CO₂ emissions in ventilation systems.

Japan Heat Exchanger Tubes Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2025 |

| Historical Period | 2020-2025 |

| Forecast Period | 2026-2034 |

| Units | Million USD |

| Scope of the Report |

Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Material Types Covered | Stainless Steel, Carbon Steel, Copper and Copper Alloys, Nickel Alloys, Titanium, Others |

| Product Types Covered | Seamless Heat Exchanger Tubes, Welded Heat Exchanger Tubes |

| Tube Configurations Covered | U-Tubes, Straight Tubes, Finned Tubes |

| Distribution Channels Covered | Direct Sales, Distributors and Suppliers |

| End Use Industries Covered | Power Generation, Oil and Gas, Chemical and Petrochemical, HVAC and Refrigeration, Food and Beverage Processing, Automotive and Aerospace, Marine and Shipbuilding, Pharmaceuticals, Others |

| Regions Covered | Kanto Region, Kansai/Kinki Region, Central/ Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, Shikoku Region |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the Japan heat exchanger tubes market performed so far and how will it perform in the coming years?

- What is the breakup of the Japan heat exchanger tubes market on the basis of material type?

- What is the breakup of the Japan heat exchanger tubes market on the basis of product type?

- What is the breakup of the Japan heat exchanger tubes market on the basis of tube configuration?

- What is the breakup of the Japan heat exchanger tubes market on the basis of distribution channel?

- What is the breakup of the Japan heat exchanger tubes market on the basis of end use industry?

- What is the breakup of the Japan heat exchanger tubes market on the basis of region?

- What are the various stages in the value chain of the Japan heat exchanger tubes market?

- What are the key driving factors and challenges in the Japan heat exchanger tubes market?

- What is the structure of the Japan heat exchanger tubes market and who are the key players?

- What is the degree of competition in the Japan heat exchanger tubes market?

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the Japan heat exchanger tubes market from 2020-2034.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the Japan heat exchanger tubes market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the Japan heat exchanger tubes industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)