Japan Hydraulic Press Market Size, Share, Trends and Forecast by Type, Application, End-User, and Region, 2026-2034

Japan Hydraulic Press Market Overview:

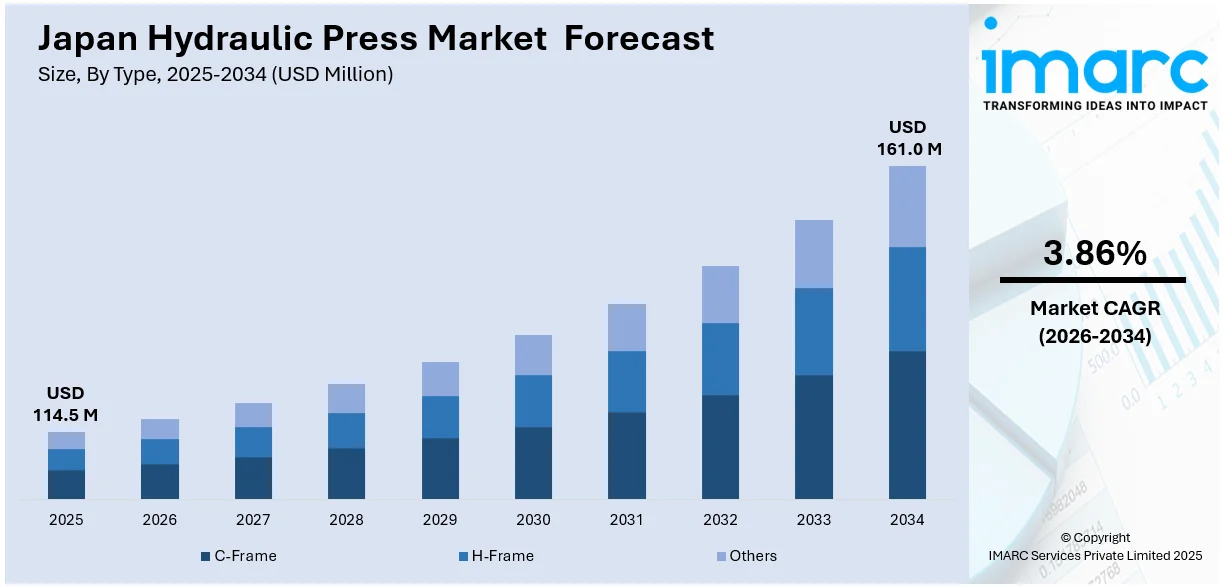

The Japan hydraulic press market size reached USD 114.5 Million in 2025. Looking forward, IMARC Group expects the market to reach USD 161.0 Million by 2034, exhibiting a growth rate (CAGR) of 3.86% during 2026-2034. The growth is fueled by technological innovation, need for accurate manufacturing, and robust industrial expansion. Moreover, greater use of automated systems and emphasis on energy-efficient solutions are fueling the Japan hydraulic press market share.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2025

|

|

Forecast Years

|

2026-2034

|

|

Historical Years

|

2020-2025

|

| Market Size in 2025 | USD 114.5 Million |

| Market Forecast in 2034 | USD 161.0 Million |

| Market Growth Rate 2026-2034 | 3.86% |

Japan Hydraulic Press Market Trends:

Adoption of Industry 4.0

Adoption of Industry 4.0 technologies in hydraulic press systems is a key driver of Japan hydraulic press market expansion. Through the integration of IoT, AI, and machine learning, manufacturers are optimizing production efficiency, quality control, and predictive maintenance functions. Data analytics and real-time monitoring offer actionable insights that enable manufacturers to optimize processes, minimize downtime, and maximize machine lifespan. Additionally, automation with hydraulic presses eliminates human error and makes processes safer and more efficient. As Japan continues to give top priority to advanced manufacturing technologies, the smart hydraulic press trend is likely to accelerate with greater customization and versatility across industries such as the automotive and aerospace sectors. For instance, as of January 2025, DAINA Corporation Ltd. plays a crucial role in the industrial machinery market by sourcing high-quality stamping presses from Japan. Specializing in progressive die technology, sourcing stamping presses from Japan, which includes hydraulic presses used in progressive die technology. Hydraulic presses are commonly utilized in industries like automotive, aerospace, and electronics for shaping and forming metal parts. Through its partnerships, DAINA supports global manufacturers with efficient, precise, and cost-effective machinery.

To get more information on this market Request Sample

Customization and Versatility for Various Applications

Customization and flexibility are the defining trends in the Japan hydraulic press market growth. Hydraulic presses are being customized to address the needs of a particular industry, ranging from the automotive to electronics sector. The manufacturers are providing solutions in a customizable manner in terms of pressure capacity, size, and functionality, allowing businesses to utilize the presses for several applications, such as stamping, forming, and molding. For instance, the "Atsugi Hydraulic Press" (AP Press) developed by Hitachi Astemo, a leader in integrated automotive systems, revolutionized the bench press in the automotive industry. Designed to meet strict demands for cost, quality, and environmental standards, the technology behind the Atsugi Hydraulic Press addresses high production requirements and user needs, enhancing production efficiency. With growing demand for specialized products and parts in Japan's industrial sectors, hydraulic presses are becoming more adaptable. These machines allow for high precision and can handle complex tasks, further enhancing productivity and reducing production costs. As Japan’s manufacturing landscape evolves, this trend of versatile hydraulic press systems will continue to fuel market growth.

Japan Hydraulic Press Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the country/regional level for 2026-2034. Our report has categorized the market based on type, application, and end-user.

Type Insights:

- C-Frame

- H-Frame

- Others

The report has provided a detailed breakup and analysis of the market based on the type. This includes C-frame, H-frame, and others.

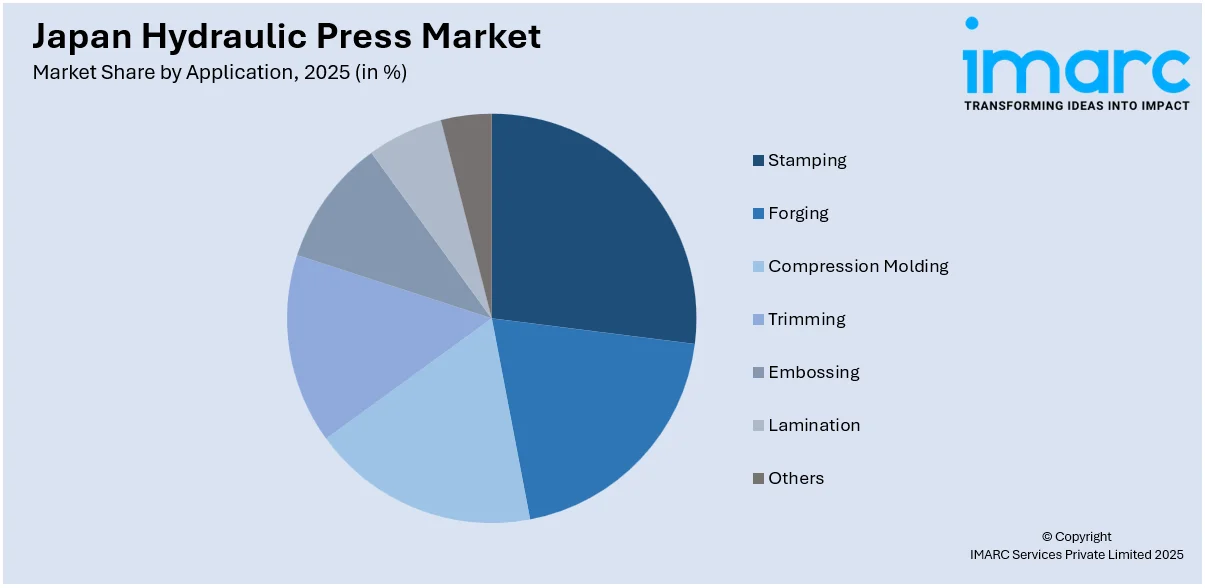

Application Insights:

Access the comprehensive market breakdown Request Sample

- Stamping

- Forging

- Compression Molding

- Trimming

- Embossing

- Lamination

- Others

A detailed breakup and analysis of the market based on the application have also been provided in the report. This includes stamping, forging, compression molding, trimming, embossing, lamination, and others.

End-User Insights:

- Automotive

- Food and Beverage

- Metal Fabrication

- Manufacturing

- Others

A detailed breakup and analysis of the market based on the end-user have also been provided in the report. This includes automotive, food and beverage, metal fabrication, manufacturing, and others.

Regional Insights:

- Kanto Region

- Kansai/Kinki Region

- Central/Chubu Region

- Kyushu-Okinawa Region

- Tohoku Region

- Chugoku Region

- Hokkaido Region

- Shikoku Region

The report has also provided a comprehensive analysis of all the major regional markets, which include Kanto Region, Kansai/Kinki Region, Central/Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, and Shikoku Region.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

Japan Hydraulic Press Market News:

- In April 2025, Kawasaki Heavy Industries announced the establishment of PT Kawasaki Precision Machinery Indonesia, aimed at selling hydraulic products in Indonesia. The new subsidiary will cater to the increasing demand for hydraulic equipment.

Japan Hydraulic Press Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2025 |

| Historical Period | 2020-2025 |

| Forecast Period | 2026-2034 |

| Units | Million USD |

| Scope of the Report |

Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Types Covered | C-frame, H-frame, Others |

| Applications Covered | Stamping, Forging, Compression Molding, Trimming, Embossing, Lamination, Others |

| End Users Covered | Automotive, Food and Beverage, Metal Fabrication, Manufacturing, Others |

| Regions Covered | Kanto Region, Kansai/Kinki Region, Central/Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, Shikoku Region |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the Japan hydraulic press market performed so far and how will it perform in the coming years?

- What is the breakup of the Japan hydraulic press market on the basis of type?

- What is the breakup of the Japan hydraulic press market on the basis of application?

- What is the breakup of the Japan hydraulic press market on the basis of end-user?

- What is the breakup of the Japan hydraulic press market on the basis of region?

- What are the various stages in the value chain of the Japan hydraulic press market?

- What are the key driving factors and challenges in the Japan hydraulic press market?

- What is the structure of the Japan hydraulic press market and who are the key players?

- What is the degree of competition in the Japan hydraulic press market?

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the Japan hydraulic press market from 2020-2034.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the Japan hydraulic press market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the Japan hydraulic press industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)