Japan Industrial Drying Equipment Market Size, Share, Trends and Forecast by Equipment Type, Application, Mode of Operation, Technology, and Region, 2026-2034

Japan Industrial Drying Equipment Market Overview:

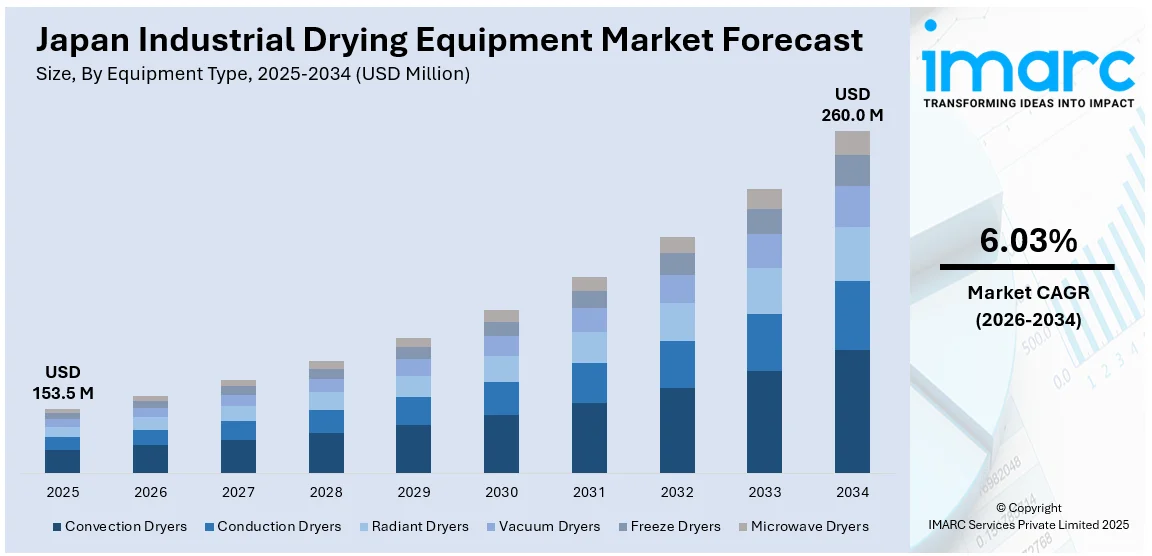

The Japan industrial drying equipment market size reached USD 153.5 Million in 2025. Looking forward, IMARC Group expects the market to reach USD 260.0 Million by 2034, exhibiting a growth rate (CAGR) of 6.03% during 2026-2034. The market is fueled by strong focus on technological advancements and energy efficiency. Electronics, chemicals, and pharmaceutical industries need to control moisture precisely to maintain product quality and meet strict regulations. Japanese industry leaders are also pioneers in researching newer and advanced drying technology that incorporates automation, IoT functions, and energy-saving attributes. This emphasis on innovation improves operational effectiveness and aligns with Japan's focus on sustainability and minimizing carbon footprints. The nation's strong manufacturing base and focus on research and development further increases the Japan industrial drying equipment market share.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2025 |

|

Forecast Years

|

2026-2034

|

|

Historical Years

|

2020-2025

|

| Market Size in 2025 | USD 153.5 Million |

| Market Forecast in 2034 | USD 260.0 Million |

| Market Growth Rate 2026-2034 | 6.03% |

Japan Industrial Drying Equipment Market Trends:

Technological Innovation and Precision Engineering

The industrial drying equipment market in Japan is dominated by a high level of technological innovation and precision engineering. Japanese industry is well known for its adherence to quality and improvement, concepts that are embedded in the industrial culture of the nation. This drives the innovation of sophisticated drying technologies that provide high efficiency, reliability, and accuracy. Electronics, pharmaceuticals, and chemicals industries that demand tight quality control and precision in the production process are large users of such high-end drying systems. Incorporating automation, intelligent controls, and real-time monitoring functionalities into drying machinery optimizes plant operations and product quality, keeping in line with Japan's general innovation and manufacturing excellence objectives. This trend reflects Japan's leadership in the global industrial drying equipment market.

To get more information on this market Request Sample

Energy Efficiency and Environmental Sustainability

In light of global environmental issues and local energy concerns, Japan's industrial drying equipment market is experiencing a transition toward energy-efficient and environmentally friendly solutions. According to industry reports, the Japanese government is vigorously working toward its aim of attaining carbon neutrality by 2050 by implementing strategies like diversifying the energy mix, enhancing energy efficiency, and speeding up the development of distributed energy resources. For instance, the Ministry of Economy, Trade and Industry (METI) of Japan has developed a Green Growth Strategy aimed at producing more than 50% of electricity from distributed renewable energy sources by 2050. Hence, companies are designing drying technologies that reduce energy consumption and carbon emissions, reflecting Japan's focus on sustainability and environmental protection. Technologies like heat recovery systems, energy-efficient compressors, and the use of environmentally friendly materials are becoming the norm in industrial dryers. Not only do these help industries meet strict environmental regulations, but they also attract environmentally aware consumers and businesses. The use of these energy-efficient drying systems helps in lowering operational costs and improving the overall environmental performance industrial operations, which further fuels the Japan industrial drying equipment market growth.

Customization and Industry-Specific Solutions

Japan's multihued industrial profile requires the creation of customized drying solutions that are industry-specific in their approach. Such industries as food processing, pharmaceutical, and chemical industries need unique drying equipment to suit special operating needs and compliance with regulatory regulations. Japanese manufacturers specialize in designing and manufacturing custom drying systems that are tailored to meet these applications, with advantages such as temperature and humidity level control, scalability, and industry-specific regulation compliance. This shift toward customization means that industries are able to sustain product quality, efficiency, and compliance with stringent standards. The capacity to offer customized drying solutions makes Japanese producers favored collaborators for businesses looking for specialized machines to fit their requirements.

Japan Industrial Drying Equipment Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the country and regional levels for 2026-2034. Our report has categorized the market based on equipment type, application, mode of operation, and technology.

Equipment Type Insights:

- Convection Dryers

- Conduction Dryers

- Radiant Dryers

- Vacuum Dryers

- Freeze Dryers

- Microwave Dryers

The report has provided a detailed breakup and analysis of the market based on the equipment type. This includes convection dryers, conduction dryers, radiant dryers, vacuum dryers, freeze dryers, and microwave dryers.

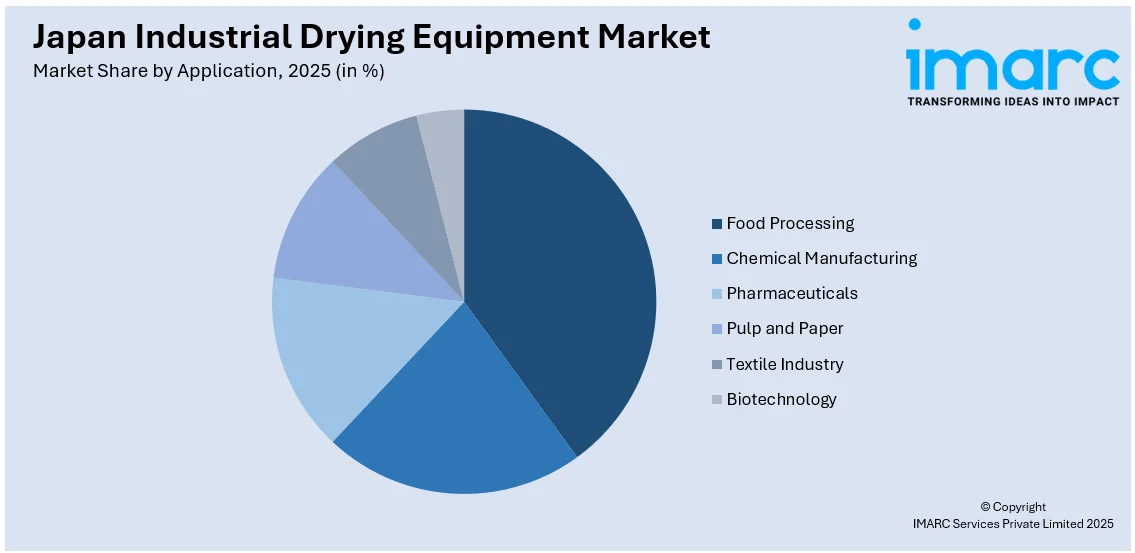

Application Insights:

Access the comprehensive market breakdown Request Sample

- Food Processing

- Chemical Manufacturing

- Pharmaceuticals

- Pulp and Paper

- Textile Industry

- Biotechnology

A detailed breakup and analysis of the market based on the application has also been provided in the report. This includes food processing, chemical manufacturing, pharmaceuticals, pulp and paper, textile industry, and biotechnology.

Mode of Operation Insights:

- Continuous Drying

- Batch Drying

- Intermittent Drying

A detailed breakup and analysis of the market based on the mode of operation has also been provided in the report. This includes continuous drying, batch drying, and intermittent drying.

Technology Insights:

- Direct Heating Technology

- Indirect Heating Technology

- Hybrid Drying Technology

- Vacuum Drying Technology

The report has provided a detailed breakup and analysis of the market based on the technology. This includes direct heating technology, indirect heating technology, hybrid drying technology, and vacuum drying technology.

Regional Insights:

- Kanto Region

- Kansai/Kinki Region

- Central /Chubu Region

- Kyushu-Okinawa Region

- Tohoku Region

- Chugoku Region

- Hokkaido Region

- Shikoku Region

The report has also provided a comprehensive analysis of all the major regional markets, which include Kanto Region, Kansai/Kinki Region, Central /Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, and Shikoku Region.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

Japan Industrial Drying Equipment Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2025 |

| Historical Period | 2020-2025 |

| Forecast Period | 2026-2034 |

| Units | Million USD |

| Scope of the Report |

Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Equipment Types Covered | Convection Dryers, Conduction Dryers, Radiant Dryers, Vacuum Dryers, Freeze Dryers, Microwave Dryers |

| Applications Covered | Food Processing, Chemical Manufacturing, Pharmaceuticals, Pulp and Paper, Textile Industry, Biotechnology |

| Modes of Operation Covered | Continuous Drying, Batch Drying, Intermittent Drying |

| Technologies Covered | Direct Heating Technology, Indirect Heating Technology, Hybrid Drying Technology, Vacuum Drying Technology |

| Regions Covered | Kanto Region, Kansai/Kinki Region, Central /Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, Shikoku Region |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the Japan industrial drying equipment market performed so far and how will it perform in the coming years?

- What is the breakup of the Japan industrial drying equipment market on the basis of equipment type?

- What is the breakup of the Japan industrial drying equipment market on the basis of application?

- What is the breakup of the Japan industrial drying equipment market on the basis of mode of operation?

- What is the breakup of the Japan industrial drying equipment market on the basis of technology?

- What is the breakup of the Japan industrial drying equipment market on the basis of region?

- What are the various stages in the value chain of the Japan industrial drying equipment market?

- What are the key driving factors and challenges in the Japan industrial drying equipment market?

- What is the structure of the Japan industrial drying equipment market and who are the key players?

- What is the degree of competition in the Japan industrial drying equipment market?

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the Japan industrial drying equipment market from 2020-2034.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the Japan industrial drying equipment market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the Japan industrial drying equipment industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)