Japan Industrial Robotics Software Market Size, Share, Trends and Forecast by Type of Software, Deployment Model, Functionality, Application, End User Industry, and Region, 2026-2034

Japan Industrial Robotics Software Market Overview:

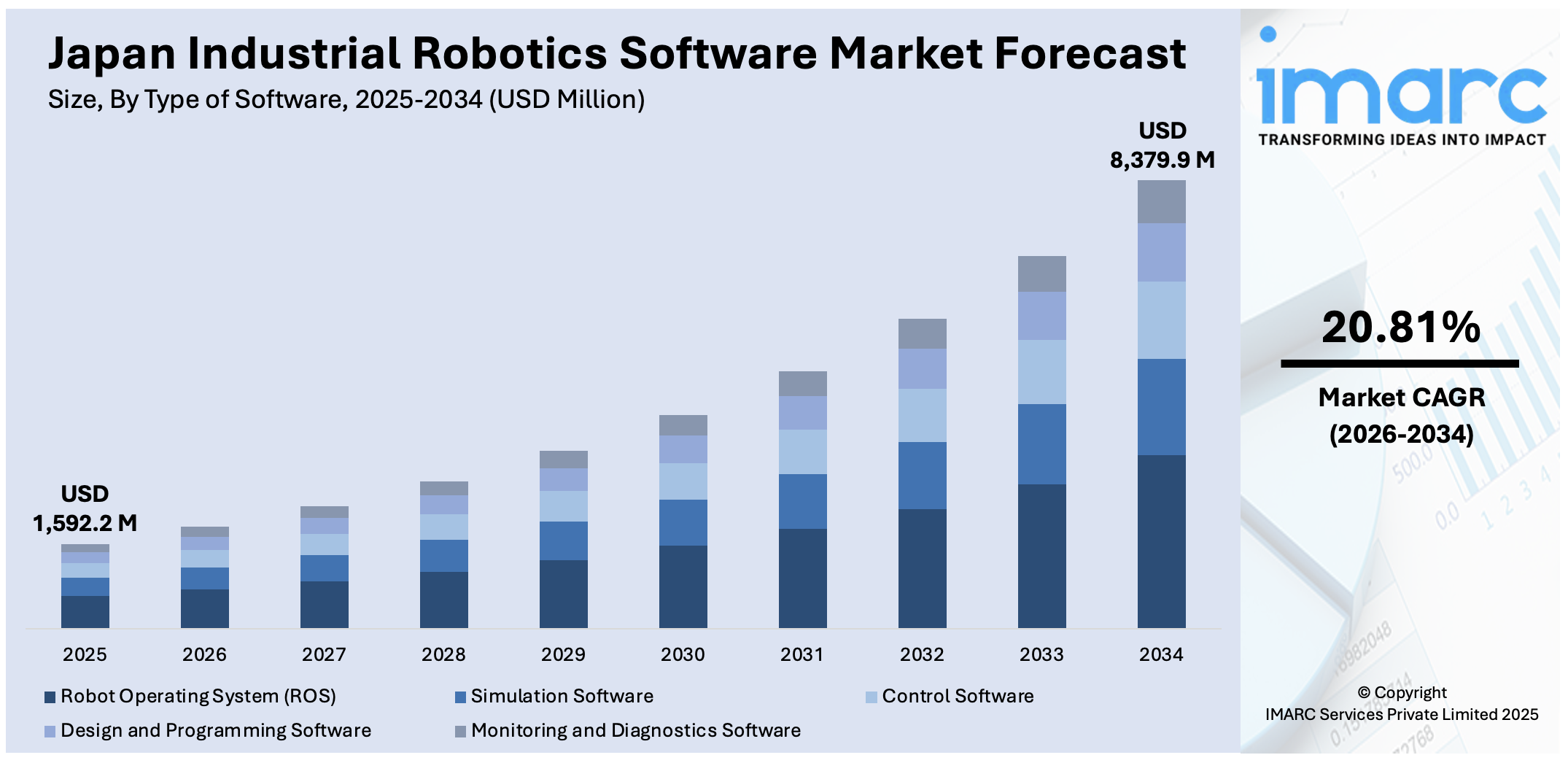

The Japan industrial robotics software market size reached USD 1,529.2 Million in 2025. Looking forward, IMARC Group expects the market to reach USD 8,379.9 Million by 2034, exhibiting a growth rate (CAGR) of 20.81% during 2026-2034. The market is mainly propelled by numerous technological innovations in robotics and AI integration. In addition, government support and Industry 4.0 initiatives are driving the product uptake. Furthermore, the growing need for automation solutions in the manufacturing industry and the ongoing advancements in smart manufacturing technologies are driving the market's steady growth. Technological advancements, automation requirement, and favorable government policies are also expanding the Japan industrial robotics software market share.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2025

|

|

Forecast Years

|

2026-2034

|

|

Historical Years

|

2020-2025

|

|

Market Size in 2025

|

USD 1,529.2 Million |

|

Market Forecast in 2034

|

USD 8,379.9 Million |

| Market Growth Rate 2026-2034 | 20.81% |

Japan Industrial Robotics Software Market Trends:

Technological Advancements in Robotics and AI Integration

The rapid advancements in robotics and artificial intelligence (AI) are playing a crucial role in the market growth. Robotics and AI are now enabling the automation of complex tasks that were previously labor-intensive and error-prone. AI-driven systems are now capable of learning and adapting to new tasks, leading to improved efficiency, precision, and flexibility. Japan has long been a leader in robotics, and its integration of AI technologies into industrial robotics systems has solidified its position at the forefront of this sector. On October 28, 2024, Yokogawa Electric Corporation announced a sales partnership with Sensyn Robotics to provide drone-related services for industrial inspections. The partnership combines Yokogawa's OpreX Robot Management Core with Sensyn Robotics' Sensyn Core platform, enabling autonomous inspections of facilities in high-risk areas such as oil and gas, chemical, and renewable energy sectors. These evolved software platforms can now offer analytics of real-time data, autonomous decision-making capabilities, and predictive maintenance, profoundly improving operational efficacy. The ability to create sophisticated robots that have the capability of executing a set of tasks that range from light assembly to detailed welding and paint applications is altering the manufacturing landscape. Industrial robotics systems in Japan are increasingly leveraging AI to improve decision-making, speed up processes, and reduce the margin of error. In addition, the use of machine learning algorithms has enabled robots to become autonomous, decreasing human interaction and minimizing safety hazards. The trend is also a driving force behind Japan industrial robotics software market growth, as companies increasingly look for software that integrates easily with hardware and maximizes robotic efficiency.

To get more information on this market Request Sample

Government Support and Industry 4.0 Initiatives

Japan's government policies and strategic initiatives surrounding Industry 4.0 are another major factor driving the market. The government has been actively promoting the use of cutting-edge technologies, including robotics and automation, across many different industries to enhance the overall competitiveness and productivity. Through subsidies, tax incentives, and research funding, Japan is fostering an environment conducive to the development and adoption of industrial robotics. The government’s focus on supporting smart manufacturing, digital transformation, and the reduction of labor costs is accelerating the growth of automation solutions within the country. The government's efforts to implement Industry 4.0, which emphasizes the integration of cyber-physical systems, IoT, and data analytics, are also contributing to the market's expansion. With an aging population and a shrinking workforce, the need for automation is critical to maintaining Japan's manufacturing capabilities. Additionally, Japanese companies are increasingly implementing robotics solutions to address labor shortages and meet global demand for high-quality products. On December 12, 2024, Kawasaki Heavy Industries launched "neoROSET," a new industrial robot programming support software designed to optimize business processes, reduce work hours, and improve quality throughout the robot implementation lifecycle. The software features an intuitive user interface, CAD file import support, and high-precision simulations using virtual controllers and digital twin technology, aimed at enhancing production facility design and operations. This strategic push is expected to further support the adoption of industrial robotics software, as businesses look for software solutions that can facilitate seamless integration of automation technologies.

Japan Industrial Robotics Software Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the country and regional levels for 2026-2034. Our report has categorized the market based on type of software, deployment model, functionality, application, and end user industry.

Type of Software Insights:

- Robot Operating System (ROS)

- Simulation Software

- Control Software

- Design and Programming Software

- Monitoring and Diagnostics Software

The report has provided a detailed breakup and analysis of the market based on the type of software. This includes Robot Operating System (ROS), simulation software, control software, design and programming software, and monitoring and diagnostics software.

Deployment Model Insights:

- On-Premises Solutions

- Cloud-Based Solutions

- Hybrid Solutions

The report has provided a detailed breakup and analysis of the market based on the deployment model. This includes on-premises solutions, cloud-based solutions, and hybrid solutions.

Functionality Insights:

- Robot Programming and Development

- Path Planning and Navigation

- Collaborative Robots (Cobots) Software

- Machine Learning and AI Integration

- Safety and Compliance Features

The report has provided a detailed breakup and analysis of the market based on the functionality. This includes robot programming and development, path planning and navigation, collaborative robots (cobots) software, machine learning and AI integration, and safety and compliance features.

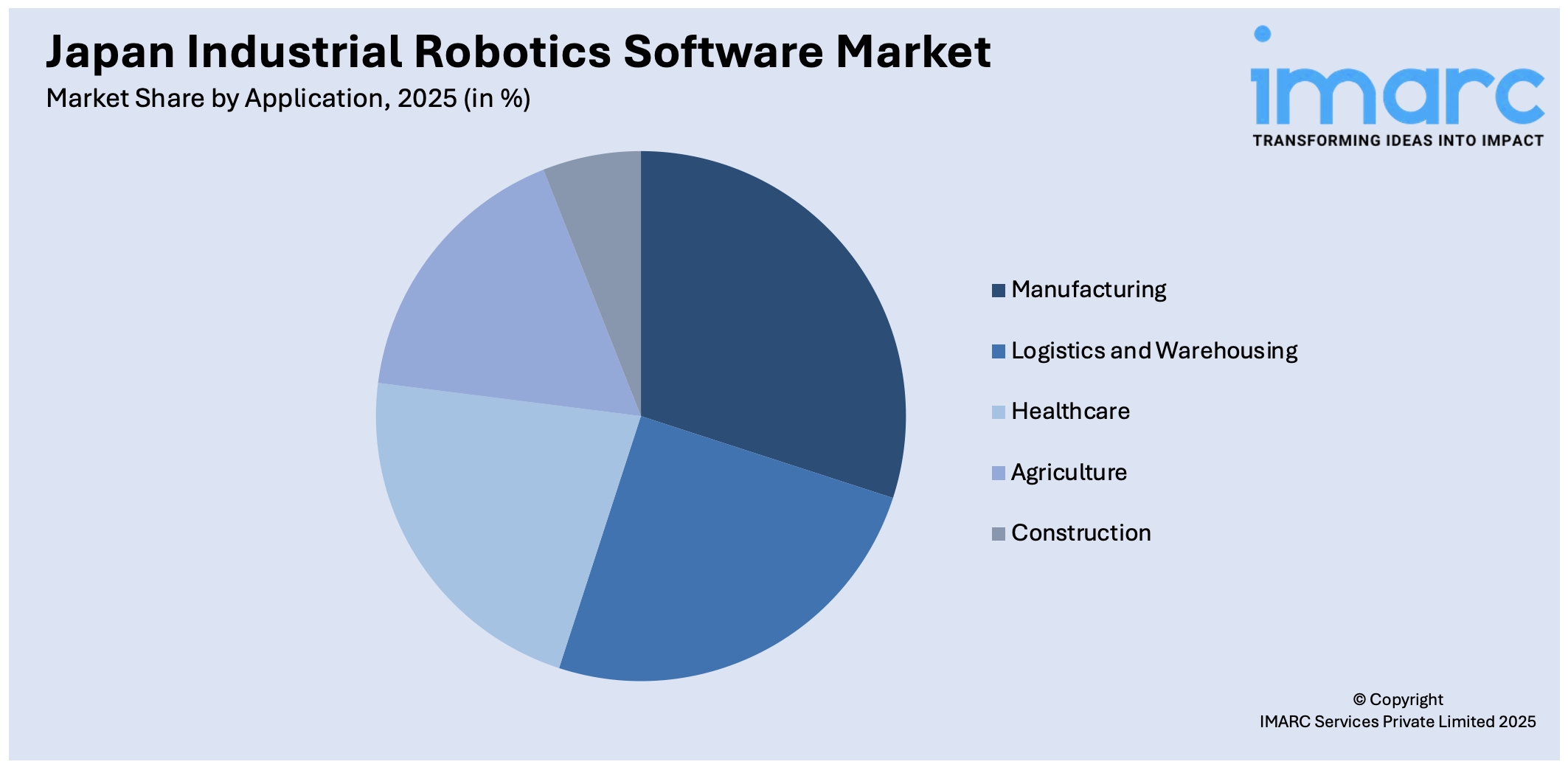

Application Insights:

Access the comprehensive market breakdown Request Sample

- Manufacturing

- Logistics and Warehousing

- Healthcare

- Agriculture

- Construction

The report has provided a detailed breakup and analysis of the market based on the application. This includes manufacturing, logistics and warehousing, healthcare, agriculture, and construction.

End User Industry Insights:

- Aerospace and Defense

- Automotive

- Electronics

- Food and Beverage

- Pharmaceuticals

The report has provided a detailed breakup and analysis of the market based on the end user industry. This includes aerospace and defense, automotive, electronics, food and beverage, and pharmaceuticals.

Regional Insights:

- Kanto Region

- Kansai/Kinki Region

- Central/Chubu Region

- Kyushu-Okinawa Region

- Tohoku Region

- Chugoku Region

- Hokkaido Region

- Shikoku Region

The report has also provided a comprehensive analysis of all the major regional markets, which include Kanto Region, Kansai/Kinki Region, Central/Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, and Shikoku Region.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

Japan Industrial Robotics Software Market News:

- On March 18, 2025, Spatial Corp. and Kawasaki Heavy Industries, Ltd. announced their collaboration to integrate Spatial’s advanced 3D software components into Kawasaki's neoROSET robot programming tool. By utilizing Spatial’s SDKs, including CGM Modeler, 3D InterOp, and HOOPS Visualize, Kawasaki aims to enhance the functionality and performance of neoROSET, which is designed to optimize industrial robot programming and system assessment.

Japan Industrial Robotics Software Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2025 |

| Historical Period | 2020-2025 |

| Forecast Period | 2026-2034 |

| Units | Million USD |

| Scope of the Report | Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Types of Software Covered | Robot Operating System (ROS), Simulation Software, Control Software, Design and Programming Software, Monitoring and Diagnostics Software |

| Deployment Models Covered | On-Premises Solutions, Cloud-Based Solutions, Hybrid Solutions |

| Functionalities Covered | Robot Programming and Development, Path Planning and Navigation, Collaborative Robots (Cobots) Software, Machine Learning and AI Integration, Safety and Compliance Features |

| Applications Covered | Manufacturing, Logistics and Warehousing, Healthcare, Agriculture, Construction |

| End User Industries Covered | Aerospace and Defense, Automotive, Electronics, Food and Beverage, Pharmaceuticals |

| Regions Covered | Kanto Region, Kansai/Kinki Region, Central/Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, Shikoku Region |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the Japan industrial robotics software market performed so far and how will it perform in the coming years?

- What is the breakup of the Japan industrial robotics software market on the basis of type of software?

- What is the breakup of the Japan industrial robotics software market on the basis of deployment model?

- What is the breakup of the Japan industrial robotics software market on the basis of functionality?

- What is the breakup of the Japan industrial robotics software market on the basis of application?

- What is the breakup of the Japan industrial robotics software market on the basis of end user industry?

- What is the breakup of the Japan industrial robotics software market on the basis of region?

- What are the various stages in the value chain of the Japan industrial robotics software market?

- What are the key driving factors and challenges in the Japan industrial robotics software market?

- What is the structure of the Japan industrial robotics software market and who are the key players?

- What is the degree of competition in the Japan industrial robotics software market?

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the Japan industrial robotics software market from 2020-2034.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the Japan industrial robotics software market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the Japan industrial robotics software industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)