Japan Machine Tool Accessories Market Size, Share, Trends and Forecast by Product, Machine Type, End-User Industry, and Region, 2026-2034

Japan Machine Tool Accessories Market Overview:

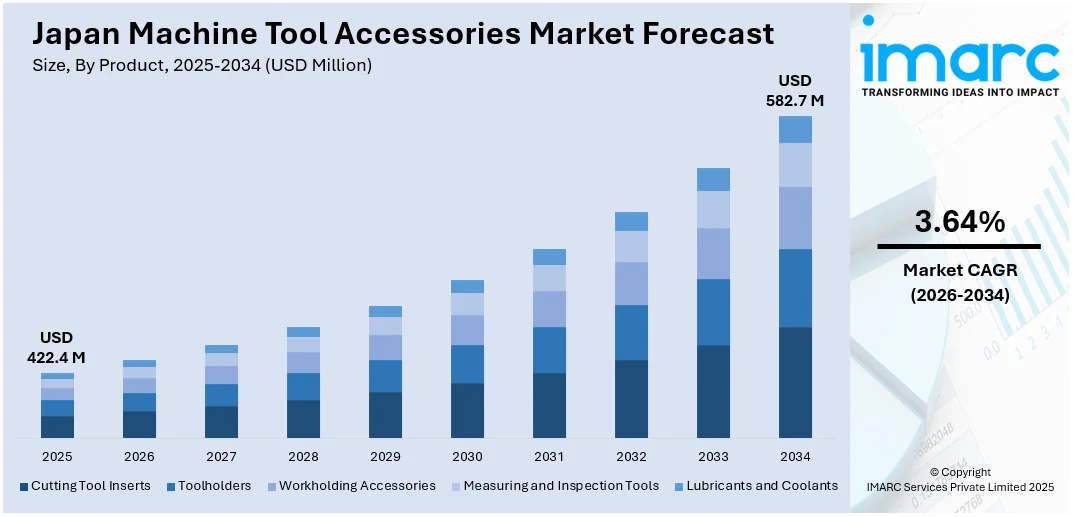

The Japan machine tool accessories market size reached USD 422.4 Million in 2025. Looking forward, IMARC Group expects the market to reach USD 582.7 Million by 2034, exhibiting a growth rate (CAGR) of 3.64% during 2026-2034. The market is driven by strong demand from its advanced automotive, aerospace, and electronics sectors. Technological innovation, precision manufacturing, and export-oriented production also bolster accessory adoption. Continuous investments in smart manufacturing and automation further enhance market growth. These dynamics contribute to the steady expansion of the Japan machine tool accessories market share.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2025

|

|

Forecast Years

|

2026-2034

|

|

Historical Years

|

2020-2025

|

| Market Size in 2025 | USD 422.4 Million |

| Market Forecast in 2034 | USD 582.7 Million |

| Market Growth Rate 2026-2034 | 3.64% |

Japan Machine Tool Accessories Market Trends:

Technological Innovation and Precision Engineering

Japan is globally recognized for its expertise in high-precision engineering and cutting-edge manufacturing technologies. The machine tool industry in the country keeps introducing innovations like 5-axis machining, using multi-tasking machines and digital twins, so it needs compatible accessories. These types of machines need specialized components, including high-performance tool holders, sensors, special coolant systems and precise fixturing tools. Machines produced in Japan focus on being precise, fast and having a high-quality finish, so advanced accessories are required to keep them at their top performance. In addition, enterprises spend large amounts on research and development, connecting smart tools such as IoT parts to improve continuous machine control and communication. The constant drive for efficiency and miniaturization, especially in industries like robotics and electronics, ensures that the need for next-generation machine tool accessories remains strong, propelling the Japan machine tool accessories market growth.

To get more information on this market Request Sample

Strong Automotive and Aerospace Manufacturing Base

Japan is home to some of the world’s leading automotive and aerospace manufacturers, including Toyota, Honda, Subaru, and Mitsubishi. These sectors demand high-volume, high-precision production, where even minor deviations can result in costly errors. Machine tool accessories—such as cutting inserts, collets, vises, and custom jigs—play a vital role in ensuring quality, repeatability, and safety during production. In aerospace manufacturing, the need for machining lightweight yet durable materials like titanium and composites further amplifies the demand for advanced, heat-resistant accessories. Additionally, growing emphasis on electric vehicles (EVs) and aircraft component exports is expanding the scope of machining operations. This high level of industrial activity ensures consistent consumption and upgrading of machine tool accessories, firmly linking the strength of these industries to the market’s ongoing growth.

Expansion of Smart Factories and Industry 4.0

Japan’s push toward smart manufacturing and digital transformation has accelerated the adoption of Industry 4.0 technologies across its factories. This shift requires integration of machine tool accessories that are compatible with automated, sensor-driven, and data-connected systems. Accessories such as intelligent tool changers, modular fixturing systems, and condition-monitoring devices enable seamless integration with CNC machines and enterprise resource planning (ERP) systems. These smart tools reduce downtime, optimize cutting performance, and enable predictive maintenance—all critical in Japan’s lean manufacturing environments. The country's focus on combining efficiency with quality production aligns perfectly with smart accessories that boost productivity without sacrificing precision. As factories become more interconnected and data-driven, the demand for advanced, digitally enabled machine tool accessories continues to grow, making digital compatibility a key market driver.

Japan Machine Tool Accessories Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the country and regional levels for 2026-2034. Our report has categorized the market based on product, machine type, and end-user industry.

Product Insights:

- Cutting Tool Inserts

- Toolholders

- Workholding Accessories

- Measuring and Inspection Tools

- Lubricants and Coolants

The report has provided a detailed breakup and analysis of the market based on the product. This includes cutting tool inserts, toolholders, workholding accessories, measuring and inspection tools, and lubricants and coolants.

Machine Type Insights:

- CNC Milling Machines

- CNC Lathes

- EDM Machines

- Grinding Machines

- Others

A detailed breakup and analysis of the market based on the machine type have also been provided in the report. This includes CNC milling machines, CNC lathes, EDM machines, grinding machines, and others.

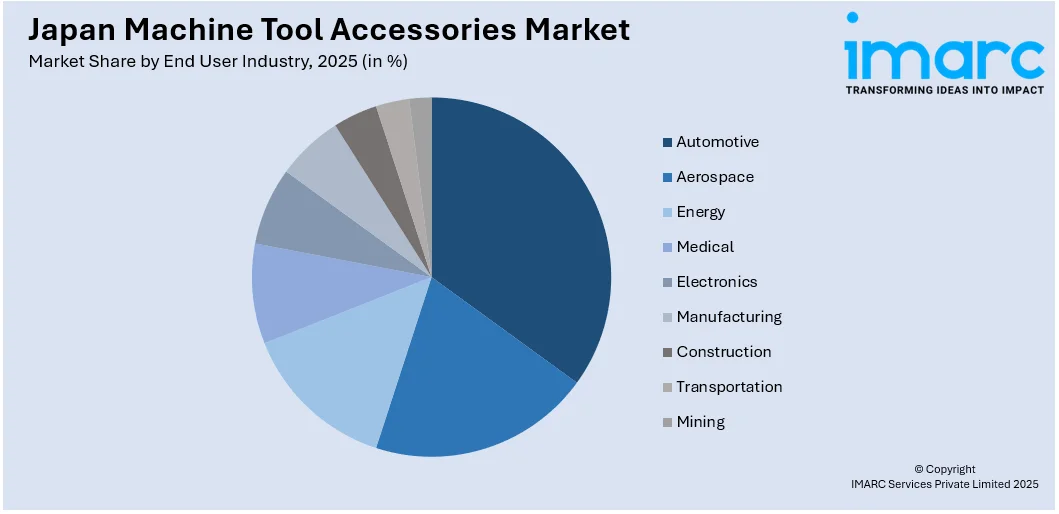

End User Industry Insights:

Access the comprehensive market breakdown Request Sample

- Automotive

- Aerospace

- Energy

- Medical

- Electronics

- Manufacturing

- Construction

- Transportation

- Mining

A detailed breakup and analysis of the market based on the end user industry have also been provided in the report. This includes automotive, aerospace, energy, medical, electronics, manufacturing, construction, transportation, and mining.

Regional Insights:

- Kanto Region

- Kansai/Kinki Region

- Central/ Chubu Region

- Kyushu-Okinawa Region

- Tohoku Region

- Chugoku Region

- Hokkaido Region

- Shikoku Region

The report has also provided a comprehensive analysis of all the major regional markets, which include the Kanto Region, Kansai/Kinki Region, Central/ Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, and Shikoku Region.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also detailed profiles of all major companies have been provided.

Japan Machine Tool Accessories Market News:

- In May 2024, from May 13 to 15, FANUC hosted "The 33rd FANUC New Products Open House Show" at its headquarters in Oshino-mura, Yamanashi Prefecture, Japan. The event featured several new goods and technologies related to industrial robots, factory automation, and ROBOMACHINES. Much attention was drawn to the new CNC system's enlarged specs and the collaborative robot that is explosion-proof.

Japan Machine Tool Accessories Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2025 |

| Historical Period | 2020-2025 |

| Forecast Period | 2026-2034 |

| Units | Million USD |

| Scope of the Report |

Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Products Covered | Cutting Tool Inserts, Toolholders, Workholding Accessories, Measuring and Inspection Tools, Lubricants and Coolants |

| Machine Types Covered | CNC Milling Machines, CNC Lathes, EDM Machines, Grinding Machines, Others |

| End-User Industries Covered | Automotive, Aerospace, Energy, Medical, Electronics, Manufacturing, Construction, Transportation, Mining |

| Regions Covered | Kanto Region, Kansai/Kinki Region, Central/ Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, Shikoku Region |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the Japan machine tool accessories market performed so far and how will it perform in the coming years?

- What is the breakup of the Japan machine tool accessories market on the basis of product?

- What is the breakup of the Japan machine tool accessories market on the basis of machine type?

- What is the breakup of the Japan machine tool accessories market on the basis of end-user industry?

- What is the breakup of the Japan machine tool accessories market on the basis of region?

- What are the various stages in the value chain of the Japan machine tool accessories market?

- What are the key driving factors and challenges in the Japan machine tool accessories market?

- What is the structure of the Japan machine tool accessories market and who are the key players?

- What is the degree of competition in the Japan machine tool accessories market?

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the Japan machine tool accessories market from 2020-2034.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the Japan machine tool accessories market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the Japan machine tool accessories industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)