Japan Metal Additive Manufacturing Market Size, Share, Trends and Forecast by Type, Component, End Use Industry, and Region, 2026-2034

Japan Metal Additive Manufacturing Market Overview:

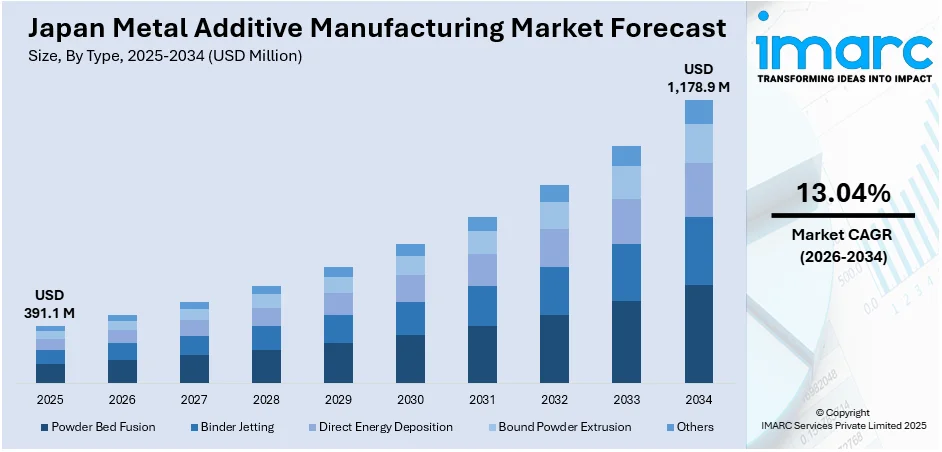

The Japan metal additive manufacturing market size reached USD 391.1 Million in 2025. Looking forward, IMARC Group expects the market to reach USD 1,178.9 Million by 2034, exhibiting a growth rate (CAGR) of 13.04% during 2026-2034. At present, the growing adoption of metal additive manufacturing to enhance the performance of electronic items while reducing their size and weight is offering a favorable market outlook. Besides this, the rising adoption of Industry 4.0 practices to achieve smarter operations and lower costs is contributing to the expansion of the Japan metal additive manufacturing market share.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2025

|

|

Forecast Years

|

2026-2034

|

|

Historical Years

|

2020-2025

|

| Market Size in 2025 | USD 391.1 Million |

| Market Forecast in 2034 | USD 1,178.9 Million |

| Market Growth Rate 2026-2034 | 13.04% |

Japan Metal Additive Manufacturing Market Trends:

Growing demand for consumer electronics

Increasing demand for consumer electronics is positively influencing the market in Japan. As people are buying smarter, more efficient, and aesthetically appealing devices, including smartphones and laptops, manufacturers are turning to 3D printing to meet the rising demand. As per industry reports, sales of smartphones in Japan increased by 7% year-on-year in 2024. The technology enables the creation of intricate internal structures and miniaturized parts that traditional manufacturing is struggling to produce. It allows quick prototyping and faster iteration cycles, helping companies bring innovative products to market more rapidly. In Japan, a country known for its advanced electronics industry, firms are adopting metal additive manufacturing to enhance product performance while reducing size and weight. This is especially useful in producing parts for wearable devices and other high-tech gadgets. The flexibility of metal 3D printing also supports limited production runs and on-demand manufacturing, aiding electronic companies in minimizing inventory and streamlining supply chains. Furthermore, the ability to integrate multiple components into a single printed part boosts durability and functionality. With rising competition and the constant need for differentiation in the consumer electronics space, Japanese manufacturers increasingly rely on metal additive manufacturing to stay ahead. This trend is not only encouraging innovations but also contributing to sustainability by reducing material waste and energy use, making the market grow steadily.

To get more information on this market Request Sample

Increasing adoption of Industry 4.0 practices

The rising adoption of Industry 4.0 practices is fueling the Japan metal additive manufacturing market growth. As per the IMARC Group, the Japan Industry 4.0 market size reached USD 9.8 Billion in 2024. As Japanese industries are employing automation, data analytics, and interconnected systems, they are integrating metal 3D printing into smart manufacturing workflows. This shift allows greater precision, customization, and real-time monitoring of production processes. Metal additive manufacturing fits well into digital factories by offering flexible and on-demand part production, reducing lead times, and minimizing material waste. It enables rapid prototyping, digital simulations, and seamless transitions from design to manufacturing, supporting innovations in sectors like automotive, aerospace, and electronics. In Japan, where technological advancements are highly valued, companies are utilizing these practices to remain competitive. The assimilation of sensors, cloud platforms, and AI with metal printing equipment helps improve quality control and production efficiency. By aligning with Industry 4.0 principles, manufacturers are achieving smarter operations, lower costs, and enhanced product performance. This digital evolution is strengthening Japan’s metal additive manufacturing market.

Japan Metal Additive Manufacturing Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the country and regional levels for 2026-2034. Our report has categorized the market based on type, component, and end use industry.

Type Insights:

- Powder Bed Fusion

- Binder Jetting

- Direct Energy Deposition

- Bound Powder Extrusion

- Others

The report has provided a detailed breakup and analysis of the market based on the type. This includes powder bed fusion, binder jetting, direct energy deposition, bound powder extrusion, and others.

Component Insights:

- Systems

- Materials

- Service and Parts

A detailed breakup and analysis of the market based on the component have also been provided in the report. This includes systems, materials, and service and parts.

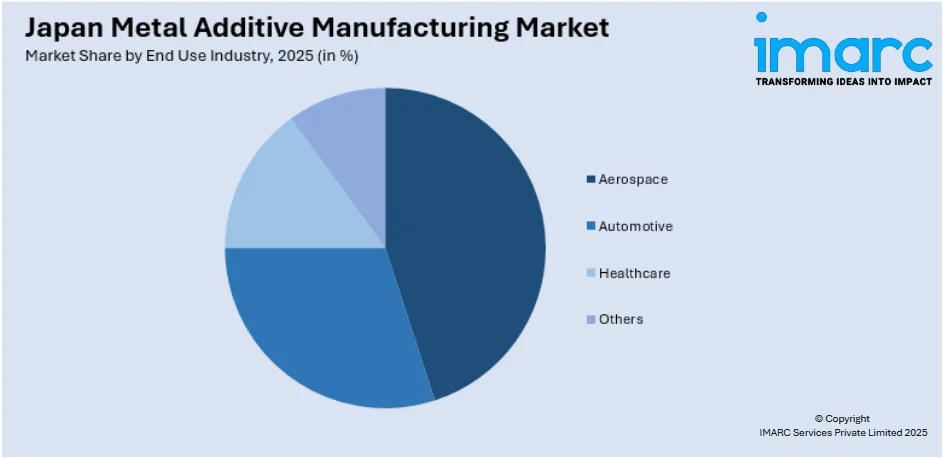

End Use Industry Insights:

Access the comprehensive market breakdown Request Sample

- Aerospace

- Automotive

- Healthcare

- Others

The report has provided a detailed breakup and analysis of the market based on the end use industry. This includes aerospace, automotive, healthcare, and others.

Regional Insights:

- Kanto Region

- Kansai/Kinki Region

- Central/Chubu Region

- Kyushu-Okinawa Region

- Tohoku Region

- Chugoku Region

- Hokkaido Region

- Shikoku Region

The report has also provided a comprehensive analysis of all the major regional markets, which include Kanto Region, Kansai/Kinki Region, Central/Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, and Shikoku Region.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

Japan Metal Additive Manufacturing Market News:

- In February 2025, Nikon launched its 922 square-meter Nikon Additive Manufacturing (AM) Technology Center in Japan. The facility was designed to assist the company's goal of transforming manufacturing while enhancing and expanding the industrial sector with innovative solutions from Nikon. The aim was to carry out research and development (R&D) of advanced metal AM technologies, as well as to offer metal AM and DfAM design services, including recommendations for enhancing and repairing metal molds and prototypes, to clients in Japan and Asia.

- In January 2024, the Smart Lander for Investigating Moon (SLIM) from the Japan Aerospace Exploration Agency (JAXA) successfully landed on the moon, marking Japan as the fifth country to accomplish a lunar landing. Metal Additive Manufacturing played a crucial role in shielding the spacecraft during the lunar landing impact by fabricating the shock absorber structures located at the end of each leg.

Japan Metal Additive Manufacturing Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2025 |

| Historical Period | 2020-2025 |

| Forecast Period | 2026-2034 |

| Units | Million USD |

| Scope of the Report |

Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Types Covered | Powder Bed Fusion, Binder Jetting, Direct Energy Deposition, Bound Powder Extrusion, Others |

| Components Covered | Systems, Materials, Service and Parts |

| End Use Industries Covered | Aerospace, Automotive, Healthcare, Others |

| Regions Covered | Kanto Region, Kansai/Kinki Region, Central/Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, Shikoku Region |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the Japan metal additive manufacturing market performed so far and how will it perform in the coming years?

- What is the breakup of the Japan metal additive manufacturing market on the basis of type?

- What is the breakup of the Japan metal additive manufacturing market on the basis of component?

- What is the breakup of the Japan metal additive manufacturing market on the basis of end use industry?

- What is the breakup of the Japan metal additive manufacturing market on the basis of region?

- What are the various stages in the value chain of the Japan metal additive manufacturing market?

- What are the key driving factors and challenges in the Japan metal additive manufacturing market?

- What is the structure of the Japan metal additive manufacturing market and who are the key players?

- What is the degree of competition in the Japan metal additive manufacturing market?

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the Japan metal additive manufacturing market from 2020-2034.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the Japan metal additive manufacturing market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the Japan metal additive manufacturing industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)