Japan Metal Cutting Tools Market Size, Share, Trends and Forecast by Tool Type, Product Type, Application, and Region, 2026-2034

Japan Metal Cutting Tools Market Overview:

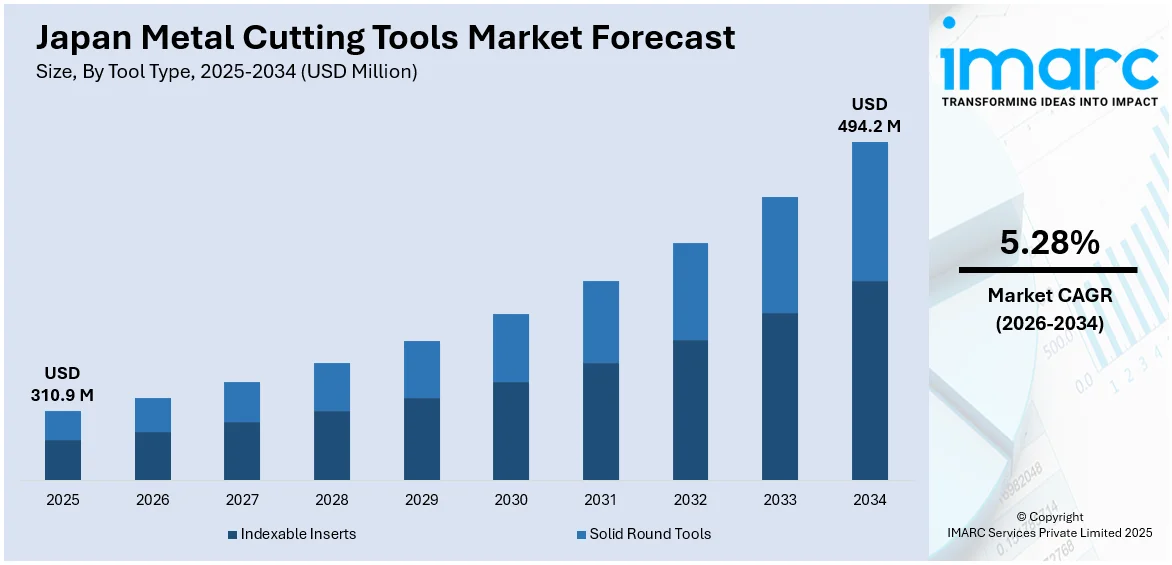

The Japan metal cutting tools market size reached USD 310.9 Million in 2025. Looking forward, IMARC Group expects the market to reach USD 494.2 Million by 2034, exhibiting a growth rate (CAGR) of 5.28% during 2026-2034. Rapid industrial automation, growing automotive and aerospace sectors, and advancements in cutting tool materials are key drivers. Increased adoption of precision manufacturing and rising demand for energy-efficient production also fuel market expansion. These factors collectively influence the Japan metal cutting tools market share positively.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2025

|

|

Forecast Years

|

2026-2034

|

|

Historical Years

|

2020-2025

|

| Market Size in 2025 | USD 310.9 Million |

| Market Forecast in 2034 | USD 494.2 Million |

| Market Growth Rate 2026-2034 | 5.28% |

Japan Metal Cutting Tools Market Trends:

Development of Advanced Coating and Tool Material Technologies

Innovation in coating technologies and high-performance tool materials is another crucial trend supporting Japan metal cutting tools market growth. Japanese manufacturers invest heavily in developing carbide, ceramic, and cubic boron nitride (CBN) tools with enhanced wear resistance and thermal stability. Advanced coatings, such as nano-composite and diamond-like carbon layers, extend tool life and improve machining accuracy, particularly for hard-to-cut materials used in aerospace and automotive industries. These technological advancements enable faster cutting speeds and reduce tool replacement frequency, contributing to more sustainable and cost-effective manufacturing. As a result, Japan's cutting tool industry maintains a technological edge, meeting rising demand for precision and durability. For instance, in March 2025, Dormer Pramet launched new high-performance turning and milling tools, designed to boost productivity through advanced materials, innovative designs, and next-gen coatings. Key products include the T5415 CVD grade for cast iron, KM chipbreaker for smoother cuts, and S-PM inserts for non-ferrous materials. Milling innovations like the versatile STD and economical SRN series offer cost-effective, efficient machining solutions. These developments highlight Dormer Pramet’s unified expertise and commitment to sustainable, customer-focused innovation in metal cutting.

To get more information on this market Request Sample

Expansion in Automotive and Aerospace Manufacturing Sectors

The resurgence and expansion of Japan’s automotive and aerospace manufacturing sectors are key contributors to Japan metal cutting tools market growth. The automotive industry’s shift towards electric vehicles (EVs) and lightweight components necessitates specialized cutting tools for new alloys and composites. Similarly, the aerospace sector demands high-precision machining for complex parts made from advanced materials. This growing industrial activity stimulates demand for innovative metal cutting tools capable of handling diverse materials while ensuring tight tolerances. Investments in R&D and collaboration between tool manufacturers and OEMs further accelerate product development, positioning Japan as a hub for high-quality metal cutting solutions in these critical sectors. For instance, in March 2025, Kyocera’s milling tool inserts won the Machinery & Robot Component Award at the 2024 'CHO' MONODZUKURI Innovative Parts and Components Awards. The award-winning PR18 Series features a new coating that enhances wear and chip resistance, extending tool life by 2.5 times compared to conventional products. Widely used in machining stainless steel and heat-resistant alloys, especially in the automotive industry, these inserts highlight Kyocera’s innovation in cutting tool technology and its contribution to industrial development.

Japan Metal Cutting Tools Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the region/country level for 2026-2034. Our report has categorized the market based on tool type, product type, and application.

Tool Type Insights:

- Indexable Inserts

- Solid Round Tools

The report has provided a detailed breakup and analysis of the market based on the tool type. This includes indexable inserts and solid round tools.

Product Type Insights:

- Lathe

- Drilling Machine

- Milling Machine

- Grinding Machine

- Others

The report has provided a detailed breakup and analysis of the market based on the product type. This includes lathe, drilling machine, milling machine, grinding machine, and others.

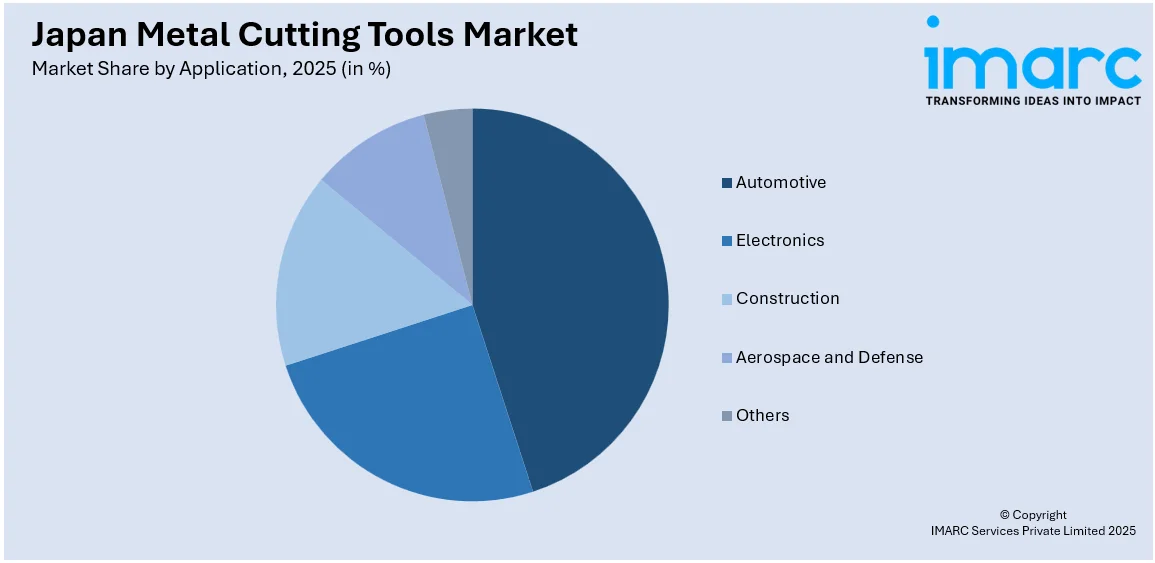

Application Insights:

Access the comprehensive market breakdown Request Sample

- Automotive

- Electronics

- Construction

- Aerospace and Defense

- Others

The report has provided a detailed breakup and analysis of the market based on the application. This includes automotive, electronics, construction, aerospace and defense, and others.

Regional Insights:

- Kanto Region

- Kansai/Kinki Region

- Central/Chubu Region

- Kyushu-Okinawa Region

- Tohoku Region

- Chugoku Region

- Hokkaido Region

- Shikoku Region

The report has also provided a comprehensive analysis of all the major regional markets, which include Kanto Region, Kansai/Kinki Region, Central/Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, and Shikoku Region.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

Japan Metal Cutting Tools Market News:

- In September 2024, Sumitomo Electric’s subsidiary A.L.M.T. Corp. acquired Esteves Group, a century-old precision diamond tool manufacturer for the wire and cable industry, from Diamond Tools Group B.V. This acquisition strengthens global business development by combining product lines, technology, and sales networks. The Esteves brand and services remain unchanged, supporting Sumitomo’s commitment to high-precision, sustainable industrial solutions.

- In August 2024, Kyocera introduced the KGZ series, new cutting tools designed for small parts machining, offering enhanced efficiency and cutting stability. Featuring a newly developed clamp structure and three unique locking mechanisms, these tools improve insert stability and cutting accuracy. The KGZ tools enable precise, high-efficiency machining essential for millimeter-scale operations.

Japan Metal Cutting Tools Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2025 |

| Historical Period | 2020-2025 |

| Forecast Period | 2026-2034 |

| Units | Million USD |

| Scope of the Report |

Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Tool Types Covered | Indexable Inserts Tools, Solid Round Tools |

| Product Types Covered | Lathe, Drilling Machine, Milling Machine, Grinding Machine, Others |

| Applications Covered | Automotive, Electronics, Construction, Aerospace and Defense, Others |

| Regions Covered | Kanto Region, Kansai/Kinki Region, Central/Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, Shikoku Region |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the Japan metal cutting tools market performed so far and how will it perform in the coming years?

- What is the breakup of the Japan metal cutting tools market on the basis of tool type?

- What is the breakup of the Japan metal cutting tools market on the basis of product type?

- What is the breakup of the Japan metal cutting tools market on the basis of application?

- What is the breakup of the Japan metal cutting tools market on the basis of region?

- What are the various stages in the value chain of the Japan metal cutting tools market?

- What are the key driving factors and challenges in the Japan metal cutting tools market?

- What is the structure of the Japan metal cutting tools market and who are the key players?

- What is the degree of competition in the Japan metal cutting tools market?

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the Japan metal cutting tools market from 2020-2034.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the Japan metal cutting tools market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the Japan metal cutting tools industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)