Japan Plastic Caps and Closure Market Size, Share, Trends and Forecast by Product Type, Raw Material, Container Type, Technology, End Use, and Region, 2025-2033

Japan Plastic Caps and Closure Market Overview:

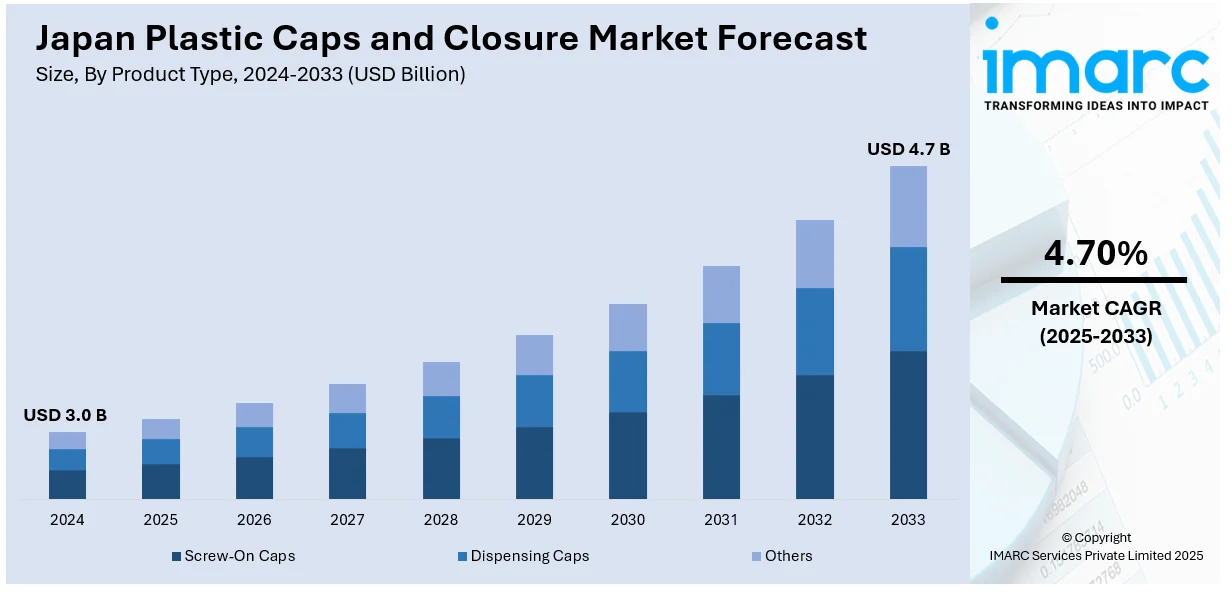

The Japan plastic caps and closure market size reached USD 3.0 Billion in 2024. Looking forward, IMARC Group expects the market to reach USD 4.7 Billion by 2033, exhibiting a growth rate (CAGR) of 4.70% during 2025-2033. The market is growing steadily, driven by the push for recyclable, mono-material solutions, adoption of standard neck finishes, and partnerships focused on reducing environmental impact through lightweight designs, improved recyclability, and integration of sustainable production technologies.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2024 |

|

Forecast Years

|

2025-2033

|

|

Historical Years

|

2019-2024

|

| Market Size in 2024 | USD 3.0 Billion |

| Market Forecast in 2033 | USD 4.7 Billion |

| Market Growth Rate 2025-2033 | 4.70% |

Japan Plastic Caps and Closure Market Trends:

Shift Toward Mono-Material Packaging Solutions

Japan’s plastic caps and closures market is experiencing a growing transition toward mono-material packaging, largely driven by the demand for improved recycling processes and compliance with sustainability targets. Traditional multi-material closures often complicate sorting and recycling, prompting manufacturers to explore designs that streamline the material recovery chain. Mono-material caps, especially those made entirely from PET, enable easier post-consumer recycling, reduce processing time, and limit the amount of non-recyclable waste generated. These caps also support the development of single-material containers, which are increasingly being favored in both domestic and export packaging standards. In April 2024, Origin Materials partnered with PackSys Global to unveil the world’s first PET cap and closure manufacturing system. This development marked a significant step in the commercial-scale production of PET closures, allowing for more efficient material use, reduced packaging weight, and extended product shelf life. By focusing on scalable, recyclable designs, this initiative aligned closely with Japan’s efforts to create a low-waste packaging infrastructure. The availability of such technology supports Japan’s broader environmental strategies, including reducing dependence on mixed plastics and advancing towards a circular packaging model. As other manufacturers take note, mono-material innovations are expected to gain further ground in shaping the future of Japan’s closure industry.

Innovation in Cap Compatibility and Standardization

The emphasis on compatibility with standardized bottle formats is impelling the Japanese plastic caps and closures market growth. As beverage producers and packaging suppliers aim to streamline production and improve recyclability, the adoption of closures that align with common neck finishes like PCO 1881 is gaining traction. These designs not only simplify the integration of sustainable materials into existing bottling lines but also promote uniformity across various product segments. Standardized caps can be produced at higher speeds, involve fewer material changeovers, and lead to reduced manufacturing waste all of which are increasingly relevant to Japan’s resource-efficient manufacturing practices. In May 2024, Origin Materials introduced a fully recyclable 100% PET cap designed to fit the PCO 1881 neck finish, a format widely used in carbonated soft drinks and still beverages. Scheduled for commercial production in Q4 2024, this cap brought practical and scalable sustainability to the mainstream beverage market. It featured a tamper-evident design and could be manufactured using virgin or recycled PET, aligning with global and domestic efforts to reduce plastic pollution. For Japan’s closing market, innovations like this not only address regulatory and environmental concerns but also help standardize design protocols, improve bottling efficiency, and expand sustainable packaging adoption across industries.

Japan Plastic Caps and Closure Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the country level for 2025-2033. Our report has categorized the market based on product type, raw material, container type, technology, and end use.

Product Type Insights:

- Screw-On Caps

- Dispensing Caps

- Others

A detailed breakup and analysis of the market based on the product type have also been provided in the report. This includes screw-on caps, dispensing caps, and others.

Raw Material Insights:

- PET

- PP

- HDPE

- LDPE

- Others

A detailed breakup and analysis of the market based on the raw material have also been provided in the report. This includes PET, PP, HDPE, LDPE, and others.

Container Type Insights:

- Plastic

- Glass

- Others

A detailed breakup and analysis of the market based on the container type have also been provided in the report. This includes plastic, glass, and others.

Technology Insights:

- Injection Molding

- Compression Molding

- Post-Mold Tamper-Evident Band

A detailed breakup and analysis of the market based on the technology have also been provided in the report. This includes injection molding, compression molding, and post-mold tamper-evident band.

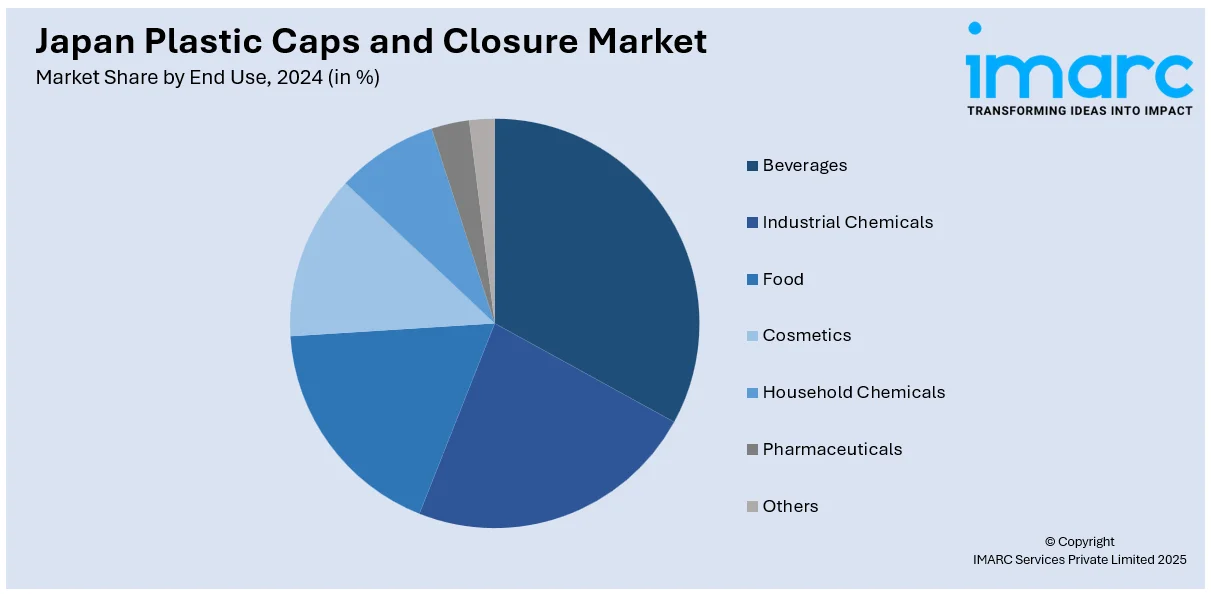

End Use Insights:

- Beverages

- Industrial Chemicals

- Food

- Cosmetics

- Household Chemicals

- Pharmaceuticals

- Others

A detailed breakup and analysis of the market based on the end use have also been provided in the report. This includes beverages, industrial chemicals, food, cosmetics, household chemicals, pharmaceuticals, and others.

Regional Insights:

- Kanto Region

- Kansai/Kinki Region

- Central/ Chubu Region

- Kyushu-Okinawa Region

- Tohoku Region

- Chugoku Region

- Hokkaido Region

- Shikoku Region

The report has also provided a comprehensive analysis of all the major regional markets, which include Kanto Region, Kansai/Kinki Region, Central/ Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, and Shikoku Region.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

Japan Plastic Caps and Closure Market News:

- February 2025: Kewpie and partners launched Japan’s first pilot to chemically recycle salad dressing caps using supercritical water. The initiative advanced the plastic caps and closures market by promoting closed-loop systems, improving recycling efficiency, and encouraging local collaboration for sustainable packaging innovations.

- January 2025: Japan’s Nissha invested in Sweden-based Blue Ocean Closures to co-develop plastic-free, fiber-based bottle caps. This move supported the Japanese plastic caps and closures market by promoting sustainable alternatives, reducing ocean plastic pollution, and advancing eco-friendly packaging through scalable vacuum press forming technology.

Japan Plastic Caps and Closure Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2024 |

| Historical Period | 2019-2024 |

| Forecast Period | 2025-2033 |

| Units | Billion USD |

| Scope of the Report |

Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Product Types Covered | Screw-On Caps, Dispensing Caps, Others |

| Raw Materials Covered | PET, PP, HDPE, LDPE, Others |

| Container Types Covered | Plastic, Glass, Others |

| Technologies Covered | Injection Molding, Compression Molding, Post-Mold Tamper-Evident Band |

| End Uses Covered | Beverages, Industrial Chemicals, Food, Cosmetics, Household Chemicals, Pharmaceuticals, Others |

| Regions Covered | Kanto Region, Kansai/Kinki Region, Central/ Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, Shikoku Region |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the Japan plastic caps and closure market performed so far and how will it perform in the coming years?

- What is the breakup of the Japan plastic caps and closure market on the basis of product type?

- What is the breakup of the Japan plastic caps and closure market on the basis raw material?

- What is the breakup of the Japan plastic caps and closure market on the basis container type?

- What is the breakup of the Japan plastic caps and closure market on the basis technology?

- What is the breakup of the Japan plastic caps and closure market on the basis end use?

- What is the breakup of the Japan plastic caps and closure market on the basis of region?

- What are the various stages in the value chain of the Japan plastic caps and closure market?

- What are the key driving factors and challenges in the Japan plastic caps and closure market?

- What is the structure of the Japan plastic caps and closure market and who are the key players?

- What is the degree of competition in the Japan plastic caps and closure market?

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the Japan plastic caps and closure market from 2019-2033.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the Japan plastic caps and closure market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the Japan plastic caps and closure industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)