Japan Powder Metallurgy Market Size, Share, Trends and Forecast by Type, Material, Manufacturing Process, Application, and Region, 2026-2034

Japan Powder Metallurgy Market Overview:

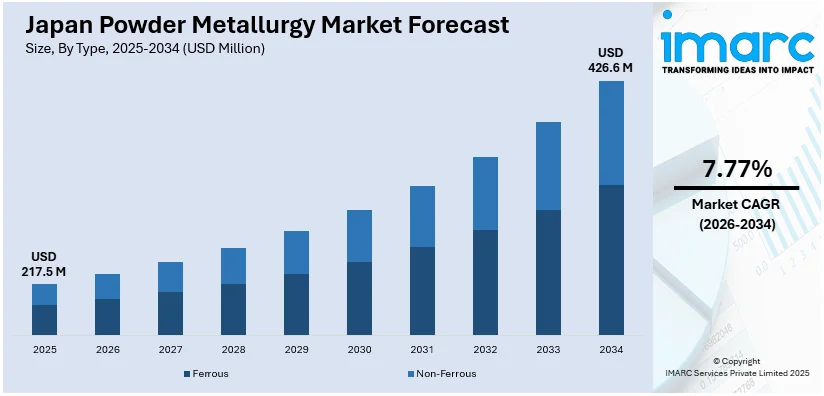

The Japan powder metallurgy market size reached USD 217.5 Million in 2025. Looking forward, IMARC Group expects the market to reach USD 426.6 Million by 2034, exhibiting a growth rate (CAGR) of 7.77% during 2026-2034. The market is driven by the rising demand for lightweight and high-strength automotive components, especially in hybrid and electric vehicles. Expanding applications across electronics, aerospace, and medical devices, driven by miniaturization trends, are further increasing the adoption of powder-based manufacturing. Additionally, supportive government policies, advancements in metal powder production, and the country’s strong manufacturing ecosystem are key factors augmenting Japan powder metallurgy market share.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2025

|

|

Forecast Years

|

2026-2034

|

|

Historical Years

|

2020-2025

|

| Market Size in 2025 | USD 217.5 Million |

| Market Forecast in 2034 | USD 426.6 Million |

| Market Growth Rate 2026-2034 | 7.77% |

Japan Powder Metallurgy Market Trends:

Rising Adoption of Powder Metallurgy in EV and Hybrid Vehicle Manufacturing

The shift towards electric and hybrid vehicles in Japan is leading to a substantial rise in the demand for powder metallurgy components. As per industry reports, as of 2023, hybrid electric vehicles (HEVs) held a dominant share of 55.1% in the Japanese market, while battery electric vehicles (EVs) and plug-in hybrid electric vehicles (PHEVs) collectively accounted for around 3.7%, reflecting a steady transition toward cleaner mobility solutions. This change is forcing automakers to put more emphasis on lightweighting technologies to improve energy efficiency and meet changing fuel economy and emissions rules. Powder metallurgy allows complex, high-strength parts to be made with high dimensional accuracy and low scrap, making it well-suited for lightweighting technologies. Major applications are gears, sprockets, bearings, and structural components utilized in electric drivetrain and brake systems. In addition, powder metallurgy enables cheap mass production of near-net-shape components, which is essential in keeping pace with competition within the high-volume automotive market. As Japan's auto industry is heavily focused on the creation of next-generation mobility technologies, such as electric and hydrogen cars, the application of powder metallurgy further broadens. This, in turn, is contributing to Japan powder metallurgy market growth. In addition to this, major OEMs and Tier-1 suppliers are collaborating with materials manufacturers to develop application-specific metal powders and optimize sintering techniques tailored to electric mobility requirements.

To get more information on this market Request Sample

Expansion into High-Performance and Non-Automotive Sectors

The market is witnessing growing demand from non-automotive sectors, particularly electronics, aerospace, medical, and industrial tools. As per industry reports, the production value of electronic devices in Japan stood at ¥279,884 Million (about USD 1.81 Billion) in April 2023, reflecting 95.7% of the previous year's level, indicating the country's robust and highly efficient electronics manufacturing sector. This robust production is driving higher demand for advanced materials and components, especially those underpinning miniaturization and heat management. In the electronics market, the demand is rising for small, heat-tolerant, and thermally conductive components to keep pace with the changing design and performance demands of new devices. Powder metallurgy is playing a key part in this transformation by allowing the creation of high-density, dimensionally precise parts with consistent material properties. In aerospace, strict material requirements and the necessity for lightweight, high-strength components make powder metallurgy an ideal solution for turbine components, fasteners, and structural components. Medical applications are also growing, especially for biocompatible and corrosion-resistant implants and surgical instruments created from titanium and stainless-steel powders. These advances represent a diversification push by Japanese powder metallurgy companies, backed by specialty alloy creation and precision production capabilities to suit the demanding requirements of high-tech industries.

Japan Powder Metallurgy Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the country and regional levels for 2026-2034. Our report has categorized the market based on type, material, manufacturing process, and application.

Type Insights:

- Ferrous

- Non-Ferrous

The report has provided a detailed breakup and analysis of the market based on the type. This includes ferrous and non-ferrous.

Material Insights:

- Titanium

- Steel

- Nickel

- Aluminum

- Others

A detailed breakup and analysis of the market based on the material have also been provided in the report. This includes titanium, steel, nickel, aluminum, and others.

Manufacturing Process Insights:

- Additive Manufacturing

- Powder Bed

- Blown Powder

- Metal Injection Molding

- Powder Metal Hot Isostatic Pressing

- Others

The report has provided a detailed breakup and analysis of the market based on the manufacturing process. This includes additive manufacturing, powder bed, blown powder, metal injection molding, powder metal hot isostatic pressing, and others.

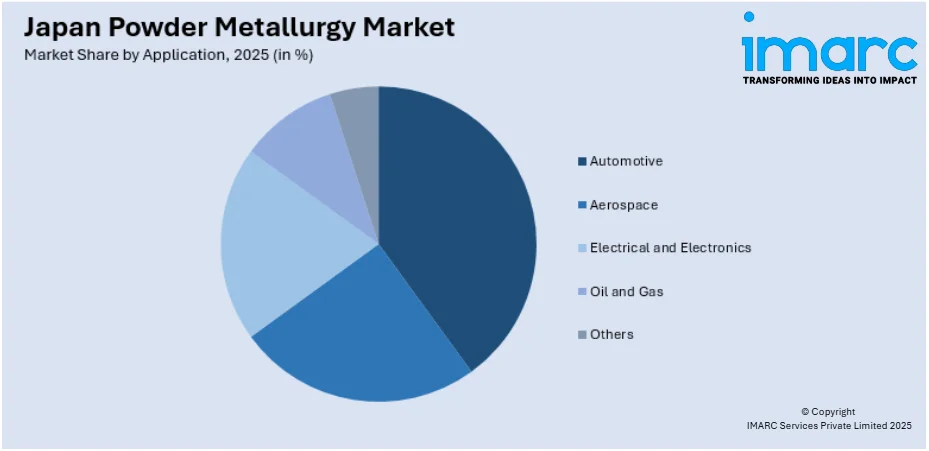

Application Insights:

Access the comprehensive market breakdown Request Sample

- Automotive

- Aerospace

- Electrical and Electronics

- Oil and Gas

- Others

A detailed breakup and analysis of the market based on the application have also been provided in the report. This includes automotive, aerospace, electrical and electronics, oil and gas, and others.

Regional Insights:

- Kanto Region

- Kansai/ Kinki Region

- Central/ Chubu Region

- Kyushu-Okinawa Region

- Tohoku Region

- Chugoku Region

- Hokkaido Region

- Shikoku Region

The report has also provided a comprehensive analysis of all the major regional markets, which include Kanto Region, Kansai/Kinki Region, Central / Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, and Shikoku Region.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

Japan Powder Metallurgy Market News:

- Nikon Corporation announced the establishment of the Nikon AM Technology Center Japan in Gyoda, Saitama Prefecture, with operations commencing on February 28, 2025. This facility is equipped with advanced metal additive manufacturing technologies, including the NXG XII 600 laser powder bed fusion system and the Lasermeister LM300A system for directed energy deposition, marking the first deployment of such equipment in Japan. The center aims to advance research and development in metal additive manufacturing and provide services to clients across Japan and Asia.

Japan Powder Metallurgy Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2025 |

| Historical Period | 2020-2025 |

| Forecast Period | 2026-2034 |

| Units | Million USD |

| Scope of the Report |

Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Types Covered | Ferrous, Non-Ferrous |

| Materials Covered | Titanium, Steel, Nickel, Aluminum, Others. |

| Manufacturing Processes Covered | Additive Manufacturing, Powder Bed, Blown Powder, Metal Injection Molding, Powder Metal Hot Isostatic Pressing, Others |

| Applications Covered | Automotive, Aerospace, Electrical and Electronics, Oil and Gas, Others |

| Regions Covered | Kanto Region, Kansai/Kinki Region, Central/ Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, Shikoku Region |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the Japan powder metallurgy market performed so far and how will it perform in the coming years?

- What is the breakup of the Japan powder metallurgy market on the basis of type?

- What is the breakup of the Japan powder metallurgy market on the basis of material?

- What is the breakup of the Japan powder metallurgy market on the basis of manufacturing process?

- What is the breakup of the Japan powder metallurgy market on the basis of application?

- What is the breakup of the Japan powder metallurgy market on the basis of region?

- What are the various stages in the value chain of the Japan powder metallurgy market?

- What are the key driving factors and challenges in the Japan powder metallurgy market?

- What is the structure of the Japan powder metallurgy market and who are the key players?

- What is the degree of competition in the Japan powder metallurgy market?

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the Japan powder metallurgy market from 2020-2034.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the Japan powder metallurgy market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the Japan powder metallurgy industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)