Japan Predictive Maintenance Market Expected to Reach USD 7,400.69 Million by 2033 - IMARC Group

Japan Predictive Maintenance Market Statistics, Outlook and Regional Analysis 2025-2033

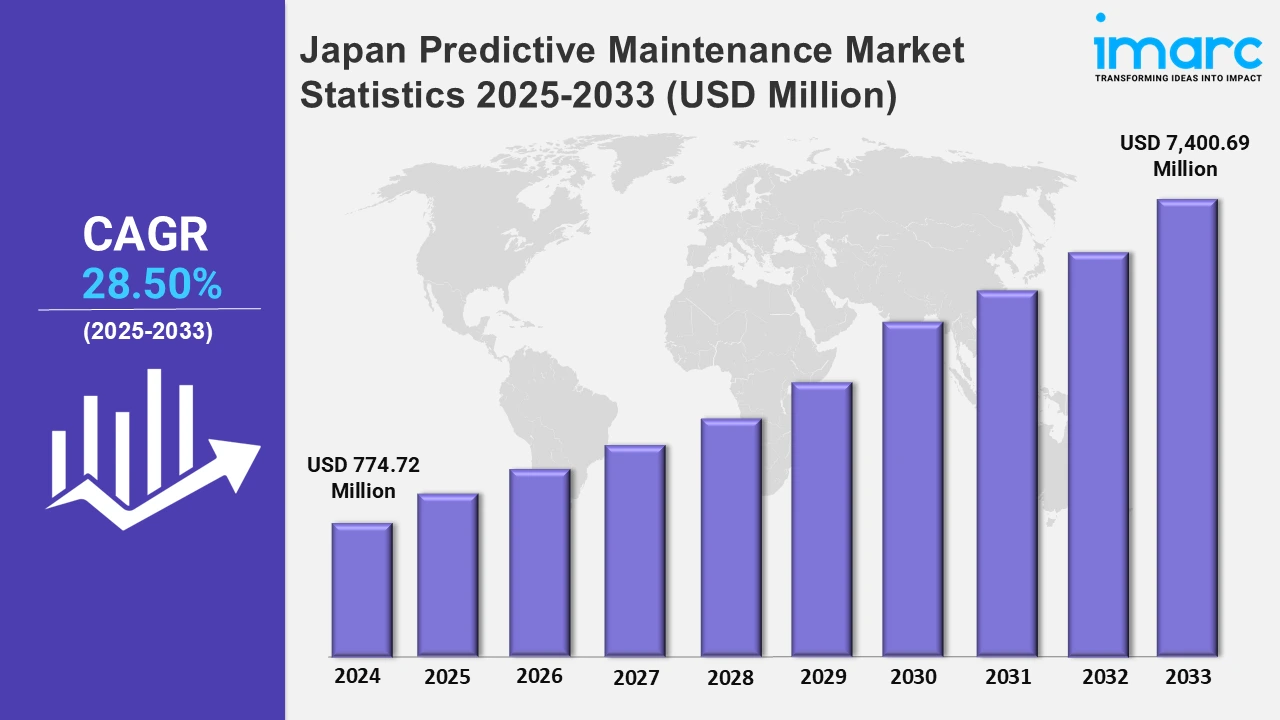

The Japan predictive maintenance market size was valued at USD 774.72 Million in 2024, and it is expected to reach USD 7,400.69 Million by 2033, exhibiting a growth rate (CAGR) of 28.50% from 2025 to 2033.

To get more information on this market, Request Sample

The market for predictive maintenance is expanding in Japan, driven by developments in artificial intelligence and IoT. These solutions support industries to optimize their operations by foreseeing equipment breakdowns, decreasing downtime, and increasing efficiency. Also, predictive maintenance solutions are seeing heightened demand in this country due to the increasing adoption of smart manufacturing, which is driven by Industry 4.0 initiatives. Companies are concentrating on combining real-time monitoring and machine learning algorithms to predict system failures and increase operational reliability. For example, Hitachi Industrial Equipment Systems introduced a machine learning-based predictive diagnosis solution in June 2024 for air compressors. This innovation reduces equipment downtime by predicting and preventing possible breakdowns by analyzing data from remote monitoring. The service, initially available for select air compressors, is expected to expand to more models, emphasizing energy-efficient and environmentally friendly operations.

Similarly, in August 2024, Asahi Kasei Engineering launched the V-MO cloud-based predictive maintenance service for ocean vessel motors in Hamburg. This service improves operating efficiency and minimizes vessel downtime with proactive defect identification and remote condition monitoring. Besides this, predictive maintenance solutions are gaining popularity in Japan, driven by the increased emphasis on sustainability and energy conservation. Furthermore, industries are under pressure to minimize their carbon footprint and comply with environmental constraints. It is also essential because it helps companies operate their equipment as efficiently as possible, which reduces expenses and energy use. Japan's aging workforce drives the development of advanced predictive maintenance systems. Consequently, the market for predictive maintenance is anticipated to grow significantly because of projects such as Asahi Kasei's V-MO system for marine applications and Hitachi's service for air compressors.

Japan Predictive Maintenance Market Statistics, By Region

The market research report has also provided a comprehensive analysis of all the major regional markets, which include Kanto region, Kansai/Kinki region, Central/ Chubu region, Kyushu-Okinawa region, Tohoku region, Chugoku region, Hokkaido region, and Shikoku region. The widespread incorporation of IoT devices is elevating the market across these regions.

Kanto Region Predictive Maintenance Market Trends:

Across all industries, the Kanto region is at the forefront of using predictive maintenance solutions. In addition, companies are utilizing IoT sensors and analytics driven by AI to keep track of the condition of their equipment and avert unplanned malfunctions. At the same time, manufacturing facilities in Kanagawa Prefecture have effectively incorporated these technologies. Such advancements are helping the region optimize operational efficiency while cutting maintenance costs. Tokyo’s robust industrial infrastructure and investments in smart technologies further drive innovation in predictive maintenance.

Kansai/Kinki Region Predictive Maintenance Market Trends:

The Kansai region, which includes Osaka, is integrating predictive maintenance primarily within the energy sector. Energy firms in Hyogo Prefecture utilize algorithms to forecast equipment performance concerns, securing more seamless operations of vital infrastructure. Overall, these companies claim that using AI-driven technologies has increased grid stability and lowered maintenance costs, making the region a benchmark for sustainable energy practices. Osaka's industrial zones are similarly adopting these technologies to improve long-term operational reliability and modernize equipment management.

Central/Chubu Region Predictive Maintenance Market Trends:

Predictive maintenance in the automotive industry is the main focus of the Chubu region. Automakers in Aichi Prefecture are using real-time analytics to track their production lines and machines. This proactive strategy has reduced breakdowns and increased productivity through manufacturing process optimization. Similarly, Nagoya's focus on promoting cooperation between tech innovators and industry speeds up the usage of these cutting-edge maintenance methods.

Kyushu-Okinawa Region Predictive Maintenance Market Trends:

The Kyushu-Okinawa region emphasizes predictive maintenance in transportation, especially railways. In Fukuoka and Kumamoto Prefectures, railway operators are using sensor technology to monitor tracks and vehicles for potential issues. This initiative has significantly improved safety standards and reduced operational disruptions. By prioritizing these advancements, the region has enhanced its reputation for efficient public transportation. The local government’s support for deploying smart sensors across networks further accelerates innovation in predictive maintenance applications.

Tohoku Region Predictive Maintenance Market Trends:

The Tohoku region is using predictive maintenance technologies in the manufacturing sector to increase productivity. Enterprises in Miyagi Prefecture are using advanced monitoring systems to anticipate and fix equipment problems before they arise. Furthermore, this technique has improved resource allocation and lessened unscheduled downtime, thereby reinforcing the industrial base's overall resilience in the area. The region’s focus on integrating AI-driven maintenance tools ensures that smaller industries also benefit from these advancements.

Chugoku Region Predictive Maintenance Market Trends:

In the Chugoku region, including Hiroshima, predictive maintenance is transforming the chemical industry. Chemical plants in Okayama Prefecture are using predictive tools to monitor equipment health, enabling timely interventions and reducing production halts. These technologies are proving essential in maintaining high safety standards and achieving consistent output in a demanding sector. Hiroshima’s focus on research partnerships further strengthens the integration of smart maintenance solutions across the chemical and related industries.

Hokkaido Region Predictive Maintenance Market Trends:

Hokkaido is incorporating predictive maintenance in its agricultural sector. Farmers in Sapporo are equipping machinery with IoT sensors to track performance and identify potential failures. This strategy ensures that machinery remains operational during crucial harvest times, thereby increasing output and lowering repair expenses. At the same time, Hokkaido stands out as a pioneer in cutting-edge farming techniques due to its emphasis on technology-driven agriculture. The agricultural cooperatives in the region primarily push the adoption of these innovative maintenance solutions.

Shikoku Region Predictive Maintenance Market Trends:

The Shikoku region, particularly Kagawa Prefecture, is utilizing predictive maintenance in the maritime industry. Shipping companies have adopted advanced monitoring systems to detect and address machinery wear in vessels. This proactive approach has decreased repair costs and increased the trustworthiness of operations. The region is improving its position in the maritime logistics industry by making investments in these technologies. Also, Shikoku remains at the forefront of marine innovation due to the collaboration between ports and tech companies.

Top Companies Leading in the Japan Predictive Maintenance Industry

The research report delivers a detailed study of the competitive landscape within Japan's predictive maintenance market. In August 2024, Asahi Kasei Engineering launched the V-MO cloud-based predictive maintenance service for ocean vessel motors in Hamburg. This service improves operating efficiency and minimizes vessel downtime with proactive defect identification and remote condition monitoring. Besides this, Hitachi Industrial Equipment Systems Co., Ltd., in June 2024, introduced its predictive diagnosis service for its maintenance team.

Japan Predictive Maintenance Market Segmentation Coverage

- On the basis of the component, the market has been bifurcated into solutions and services. They leverage advanced analytics, IoT sensors, and AI-driven insights to detect equipment issues early, reducing downtime, optimizing operations, and extending asset lifespans effectively.

- Based on the deployment, the market is categorized into on-premises and cloud. This system integrates seamlessly with on-premises systems for secure and localized control. At the same time, cloud platforms are adopted for real-time, scalable data analysis and collaborative decision-making across diverse operational environments.

- On the basis of the end user, the market has been divided into energy and utilities, transportation, manufacturing, healthcare, and others. Predictive maintenance supports all these sectors by enhancing operational efficiency, reducing disruptions, and enabling data-driven insights for proactive asset management across critical industrial sectors.

| Report Features | Details |

|---|---|

| Market Size in 2024 | USD 774.72 Million |

| Market Forecast in 2033 | USD 7,400.69 Million |

| Market Growth Rate 2025-2033 | 28.50% |

| Units | Million USD |

| Scope of the Report |

Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Components Covered | Solutions, Services |

| Deployments Covered | On-premise, Cloud |

| End Users Covered | Energy and Utilities, Transportation, Manufacturing, Healthcare, Others |

| Regions Covered | Kanto Region, Kansai/Kinki Region, Central/ Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, Shikoku Region |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Browse IMARC Related Reports on Predictive Maintenance Market

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Inquire Before Buying

Inquire Before Buying

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

.webp)

.webp)