Japan Robotics in Manufacturing Market Size, Share, Trends and Forecast by Component, Type, End User, and Region, 2026-2034

Japan Robotics in Manufacturing Market Overview:

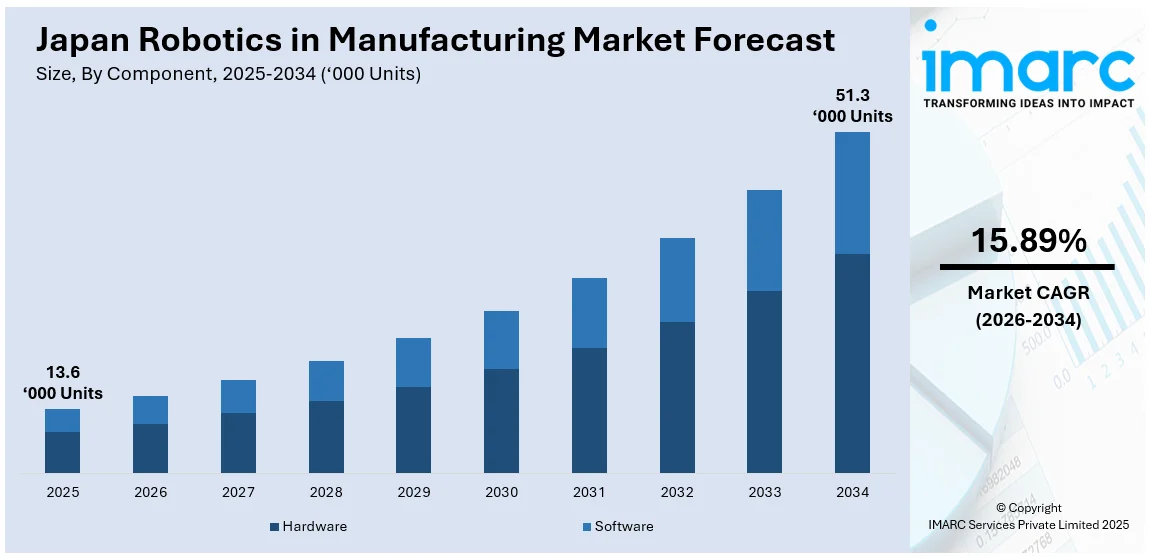

The Japan robotics in manufacturing market size reached 13.6 Thousand Units in 2025. Looking forward, IMARC Group expects the market to reach 51.3 Thousand Units by 2034, exhibiting a growth rate (CAGR) of 15.89% during 2026-2034. The market is driven by a shrinking workforce, increasing labor costs, and the urgent need for automation to sustain productivity. Strong government support, increasing research and development (R&D) investments, and global leadership in precision engineering further accelerate robotic integration across automotive, electronics, and heavy industries. Additionally, the demand for smart factories, the need for enhanced operational efficiency, and AI-driven robotics are important factors augmenting Japan robotics in manufacturing market share.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2025 |

|

Forecast Years

|

2026-2034

|

|

Historical Years

|

2020-2025

|

| Market Size in 2025 | 13.6 Thousand Units |

| Market Forecast in 2034 | 51.3 Thousand Units |

| Market Growth Rate 2026-2034 | 15.89% |

Japan Robotics in Manufacturing Market Trends:

Adoption of Collaborative Robots (Cobots) in SME Manufacturing

A notable trend in the market is the increasing adoption of collaborative robots (cobots) by small and medium-sized enterprises (SMEs). Unlike traditional industrial robots that operate in isolation and require extensive safety enclosures, cobots are engineered to function safely alongside human workers, allowing for seamless integration into existing production setups without major infrastructural modifications. In Japan, SMEs constitute approximately 99.7% of all businesses, underscoring their central role in the national economy. These enterprises often operate within spatial and financial constraints, compounded by persistent labor shortages. In response, many are turning to cobots to boost productivity while minimizing the need for additional workforce. Cobots are particularly effective in handling repetitive, low-skill tasks such as pick-and-place operations, inspection, or component assembly, freeing human workers for more value-added activities. Besides this, the ongoing advancement in safety features, intuitive programming interfaces, and cost reductions is making cobot deployment feasible and supporting Japan robotics in the manufacturing market growth. Japan's mature industrial base, combined with the government's push for digital transformation under initiatives like Society 5.0, is further catalyzing the spread of cobots, particularly in automotive components, electronics assembly, and precision tooling sectors.

To get more information on this market Request Sample

Aging Workforce and Demographic-Driven Automation Demand

Japan's manufacturing sector is significantly reshaped by demographic pressures, notably a rapidly aging population and sustained decline in birth rates. According to industry reports, the country's senior population has reached a record 36.25 million, with individuals aged 65 or older now comprising nearly one-third of the total population. The median age of the workforce continues to rise, and a diminishing supply of younger labor is creating a critical shortfall across industrial operations. This demographic imbalance has shifted automation from a strategic advantage to an operational imperative. Manufacturers, particularly in labor-intensive sectors such as metal fabrication, industrial machinery, and logistics equipment, are increasingly deploying robotic systems to address staffing constraints and maintain output levels. Unlike earlier automation models focused solely on high-volume production, the current wave emphasizes adaptive, multi-functional robotic solutions capable of responding to varied production needs. Government support through financial incentives and technical training initiatives further accelerates adoption. For many firms, especially those in rural or remote regions where labor shortages are more acute, robotics now serves as a cornerstone of business continuity, export reliability, and competitive manufacturing performance.

Japan Robotics in Manufacturing Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the country and regional levels for 2026-2034. Our report has categorized the market based on component, type, and end user.

Component Insights:

- Hardware

- Software

The report has provided a detailed breakup and analysis of the market based on the component. This includes hardware and software.

Type Insights:

- Industrial Robots

- Collaborative Robots (Cobots)

- SCARA Robots

- Cartesian Robots

A detailed breakup and analysis of the market based on the type have also been provided in the report. This includes industrial robots, collaborative robots (Cobots), SCARA robots, and cartesian robots.

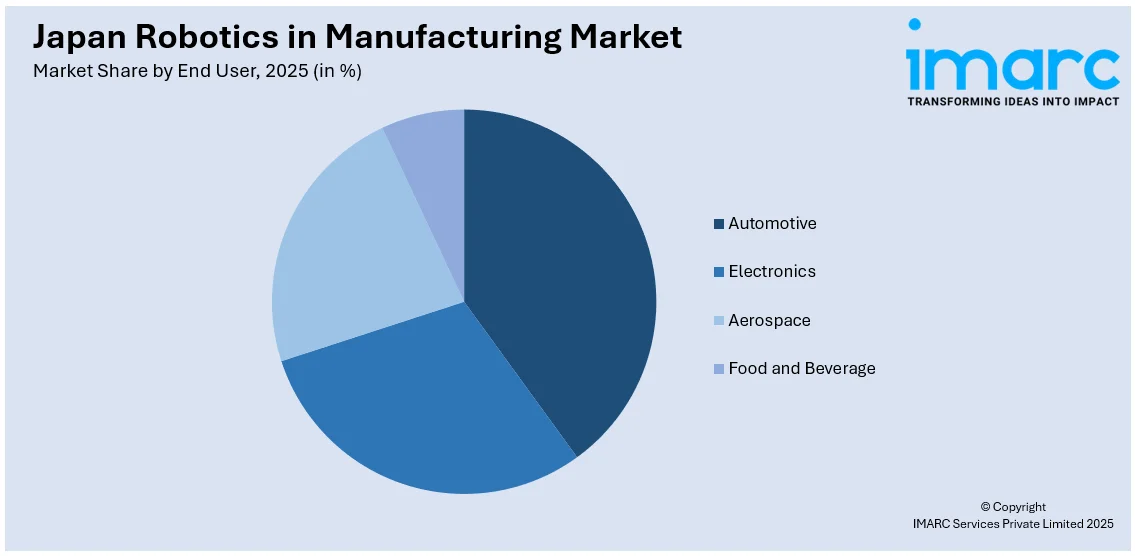

End User Insights:

Access the comprehensive market breakdown Request Sample

- Automotive

- Electronics

- Aerospace

- Food and Beverage

The report has provided a detailed breakup and analysis of the market based on the end user. This includes automotive, electronics, aerospace, and food and beverage.

Regional Insights:

- Kanto Region

- Kansai/Kinki Region

- Central/Chubu Region

- Kyushu-Okinawa Region

- Tohoku Region

- Chugoku Region

- Hokkaido Region

- Shikoku Region

The report has also provided a comprehensive analysis of all the major regional markets, which include Kanto Region, Kansai/Kinki Region, Central/Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, and Shikoku Region.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

Japan Robotics in Manufacturing Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2025 |

| Historical Period | 2020-2025 |

| Forecast Period | 2026-2034 |

| Units | Thousand Units |

| Scope of the Report |

Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Components Covered | Hardware, Software |

| Types Covered | Industrial Robots, Collaborative Robots (Cobots), SCARA Robots, Cartesian Robots |

| End Users Covered | Automotive, Electronics, Aerospace, Food and Beverage |

| Regions Covered | Kanto Region, Kansai/Kinki Region, Central/Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, Shikoku Region |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the Japan robotics in manufacturing market performed so far and how will it perform in the coming years?

- What is the breakup of the Japan robotics in manufacturing market on the basis of component?

- What is the breakup of the Japan robotics in manufacturing market on the basis of type?

- What is the breakup of the Japan robotics in manufacturing market on the basis of end user?

- What is the breakup of the Japan robotics in manufacturing market on the basis of region?

- What are the various stages in the value chain of the Japan robotics in manufacturing market?

- What are the key driving factors and challenges in the Japan robotics in manufacturing market?

- What is the structure of the Japan robotics in manufacturing market and who are the key players?

- What is the degree of competition in the Japan robotics in manufacturing market?

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the Japan robotics in manufacturing market from 2020-2034.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the Japan robotics in manufacturing market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the Japan robotics in manufacturing industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)