Japan Smart Factory Automation Market Size, Share, Trends and Forecast by Technology, Component, Deployment Mode, Industry Vertical, and Region, 2026-2034

Japan Smart Factory Automation Market Overview:

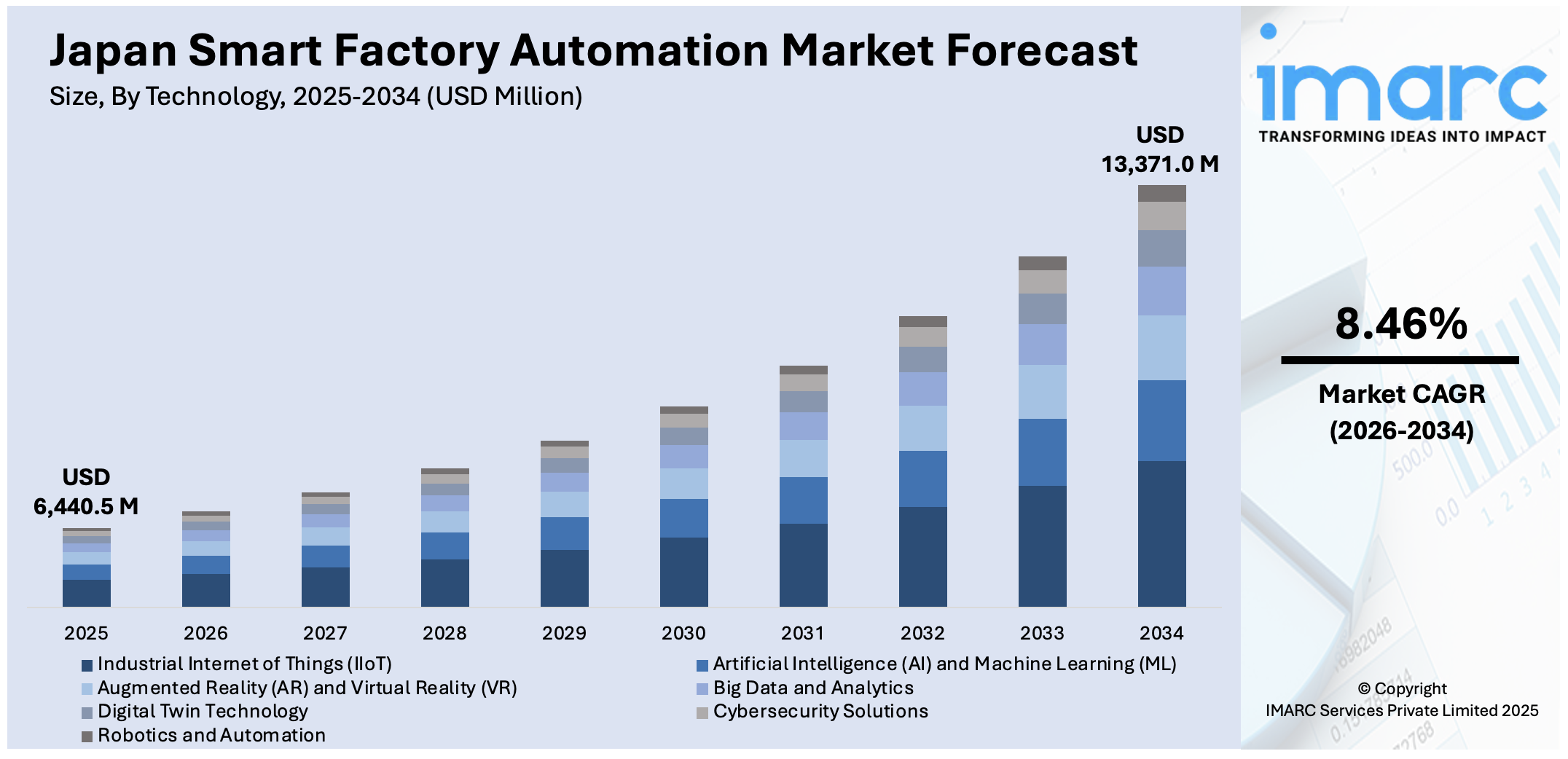

The Japan smart factory automation market size reached USD 6,440.5 Million in 2025. Looking forward, IMARC Group expects the market to reach USD 13,371.0 Million by 2034, exhibiting a growth rate (CAGR) of 8.46% during 2026-2034. The market is fueled by the development of robotics, Industrial IoT, and digital twin technologies. Intelligent systems are being highly used by manufacturers to improve productivity, minimize downtime, and enhance operational efficiency. As manufacturing facilities continue to adopt digital technologies and build advanced digital infrastructure, there is growing demand for scalable, flexible, and highly automated production solutions across key industrial sectors reflecting in the significant Japan smart factory automation market share.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2025

|

|

Forecast Years

|

2026-2034

|

|

Historical Years

|

2020-2025

|

|

Market Size in 2025

|

USD 6,440.5 Million |

|

Market Forecast in 2034

|

USD 13,371.0 Million |

| Market Growth Rate 2026-2034 | 8.46% |

Japan Smart Factory Automation Market Trends:

Integration of Advanced Robotics and Autonomous Systems

Japan remains at the forefront of robotics adoption in smart factory settings. More autonomous systems are being used to carry out intricate manufacturing processes with minimal human involvement. These high-tech robotics are combined with intelligent software platforms that enable real-time modifications according to production line requirements. For instance, in October 2024, Horizon Smart Factory 2024 in Japan will showcase cutting-edge automation technologies, such as AGVs, robotics, and AI, to enable autonomous printing, finishing, and packaging. Moreover, the trend is also complemented by collaborative robots that can work safely alongside human labor, enhancing efficiency and flexibility. With high-precision movements, responsiveness, and data-exchange features, robotic platforms are revamping conventional models of production to become extremely responsive in nature. As smart factories grow, seamless cooperation between robotic platforms and digital systems forms the bedrock of optimized cycles of production. This is one of the major impetuses for Japan smart factory automation market growth, making scalable and smart manufacturing solutions relevant to global needs.

To get more information on this market Request Sample

Embracing Industrial IoT and Predictive Maintenance

The use of Industrial Internet of Things (IIoT) technologies is transforming factory automation in Japan. Intelligent sensors embedded along production lines are now a part of standard equipment to capture real-time operation information. If such streams of data are analyzed by cloud platforms, they facilitate predictive maintenance patterns that minimize downtime and avoid equipment breakdowns. Factories gain intense operational insight, which leads to the early identification of inefficiencies or malfunctions. In addition, IIoT ecosystems are central to enhancing quality control, energy optimization, and workflow integration. IIoT digital connectivity also facilitates smooth communication between machines and enterprise systems, encouraging coordinated decision-making. This technology evolution underpins Japan's strategic goal of sustaining manufacturing excellence amidst labor shortages and aging equipment. Through integrating predictive intelligence into systems, manufacturers develop a new level of reliability and affordability.

Digital Twins Emergence for Operation Simulation

The use of digital twin technology is emerging as a hallmark trend in Japan's smart factory automation industry. Digital twins are computerized replicas of physical systems, allowing real-time simulation, monitoring, and optimization of production processes. For example, In September 2023, Toyota opened a new manufacturing facility with an emphasis on human-centered monozukuri that incorporates digital technology to maximize productivity, shorten lead times, and support factory carbon neutrality to help shape future carmaking. Furthermore, by replicating the behavior of machines and processes, factories can test new configurations risk-free, optimize settings, and predict potential problems ahead of physical implementation. This forward-looking strategy minimizes waste, streamlines product development time, and guarantees business continuity. Digital twin environments are typically improved through artificial intelligence and big data analytics implementation, enabling smart scenario modeling and performance prediction. With increasing manufacturing sophistication, the capability to evaluate and modify systems in a virtual context without halting real-time operations is yielding immense benefits. The intensifying dependence on the same is a reflection of Japan's boosting smart factory automation capabilities, as the nation shifts towards entirely digitized, agile manufacturing environments.

Japan Smart Factory Automation Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the country and regional levels for 2026-2034. Our report has categorized the market based on technology, component, deployment mode, and industry vertical.

Technology Insights:

- Industrial Internet of Things (IIoT)

- Artificial Intelligence (AI) and Machine Learning (ML)

- Augmented Reality (AR) and Virtual Reality (VR)

- Big Data and Analytics

- Digital Twin Technology

- Cybersecurity Solutions

- Robotics and Automation

The report has provided a detailed breakup and analysis of the market based on the technology. This includes industrial Internet of Things (IIoT), artificial intelligence (AI) and machine learning (ML), augmented reality (AR) and virtual reality (VR), big data and analytics, digital twin technology, cybersecurity solutions, and robotics and automation.

Component Insights:

- Sensors and Actuators

- Industrial Robots

- Human-Machine Interface (HMI)

- Industrial Control Systems

- SCADA

- PLC

- DCS

- Networking and Communication Systems

- Software and Cloud Solutions

A detailed breakup and analysis of the market based on the component have also been provided in the report. This includes sensors and actuators, industrial robots, human-machine interface (HMI), industrial control Systems (SCADA, PLC, and DCS), networking and communication systems, and software and cloud solutions.

Deployment Mode Insights:

- On-Premises

- Cloud-Based

The report has provided a detailed breakup and analysis of the market based on the deployment mode. This includes on-premises and cloud-based.

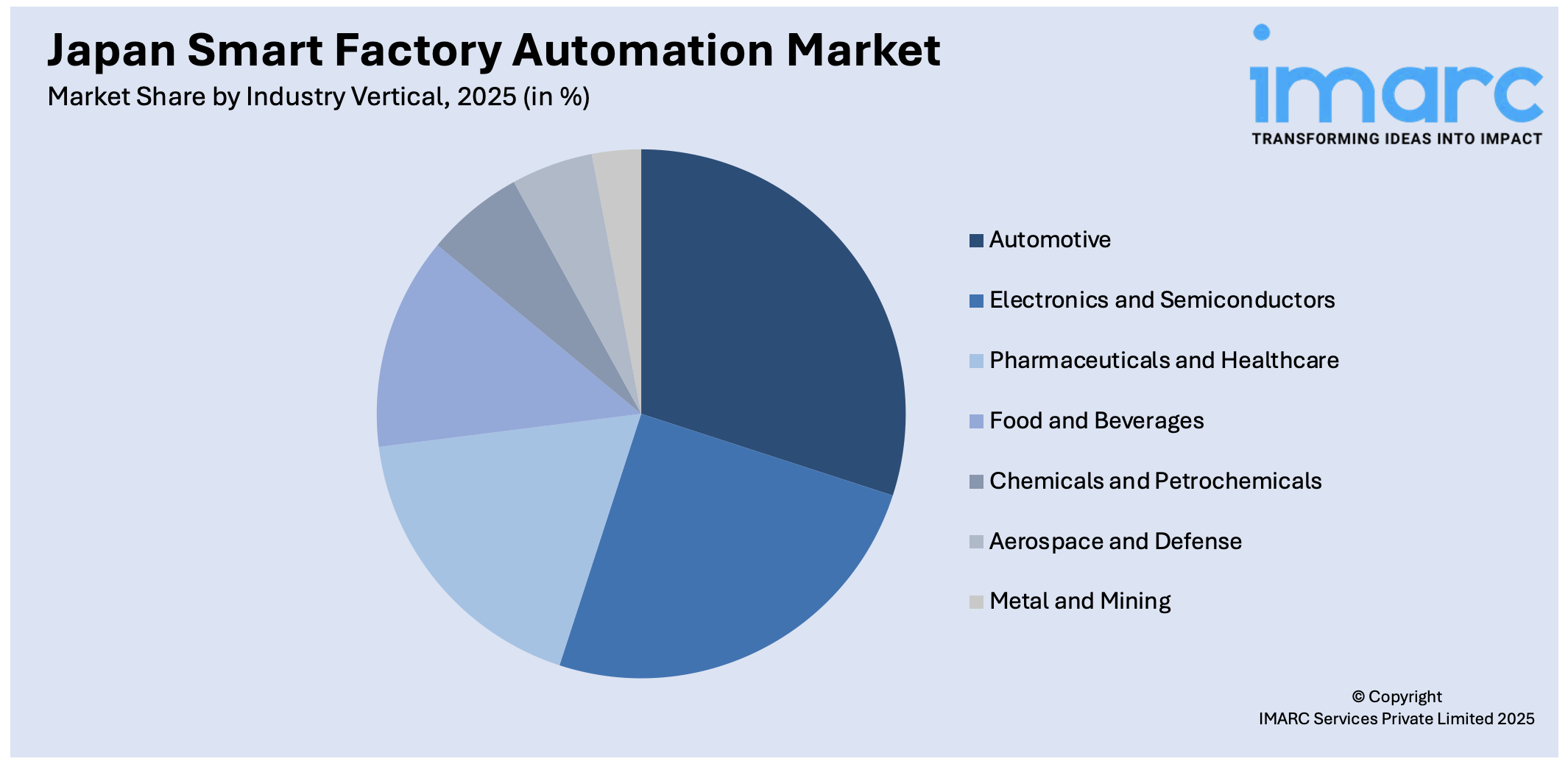

Industry Vertical Insights:

Access the comprehensive market breakdown Request Sample

- Automotive

- Electronics and Semiconductors

- Pharmaceuticals and Healthcare

- Food and Beverages

- Chemicals and Petrochemicals

- Aerospace and Defense

- Metal and Mining

A detailed breakup and analysis of the market based on the industry vertical have also been provided in the report. This includes automotive, electronics and semiconductors, pharmaceuticals and healthcare, food and beverages, chemicals and petrochemicals, aerospace and defense, and metal and mining.

Regional Insights:

- Kanto Region

- Kansai/Kinki Region

- Central/ Chubu Region

- Kyushu-Okinawa Region

- Tohoku Region

- Chugoku Region

- Hokkaido Region

- Shikoku Region

The report has also provided a comprehensive analysis of all the major regional markets, which include Kanto region, Kansai/Kinki region, Central/Chubu region, Kyushu-Okinawa region, Tohoku region, Chugoku region, Hokkaido region, and Shikoku region.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

Japan Smart Factory Automation Market News:

- In October 2024, Komori Corporation introduces its revamped KGC Smart Factory in Tsukuba, with advanced automation systems such as KP-Connect Pro. The revolution improves efficiency and productivity and works as an open innovation platform for the printing sector. The smart factory focuses on collaboration, sustainability, and technological innovation.

Japan Smart Factory Automation Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2025 |

| Historical Period | 2020-2025 |

| Forecast Period | 2026-2034 |

| Units | Million USD |

| Scope of the Report |

Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Technologies Covered | Industrial Internet of Things (IIoT), Artificial Intelligence (AI) and Machine Learning (ML), Augmented Reality (AR) and Virtual Reality (VR), Big Data and Analytics, Digital Twin Technology, Cybersecurity Solutions, Robotics and Automation |

| Components Covered |

|

| Deployment Modes Covered | On-Premises, Cloud-Based |

| Industry Verticals Covered | Automotive, Electronics and Semiconductors, Pharmaceuticals and Healthcare, Food and Beverages, Chemicals and Petrochemicals, Aerospace and Defense, Metal and Mining |

| Regions Covered | Kanto Region, Kansai/Kinki Region, Central/Chubu Region, Kyushu-Okinawa Region, Tohoku Region, Chugoku Region, Hokkaido Region, Shikoku Region |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the Japan smart factory automation market performed so far and how will it perform in the coming years?

- What is the breakup of the Japan smart factory automation market on the basis of technology?

- What is the breakup of the Japan smart factory automation market on the basis of component?

- What is the breakup of the Japan smart factory automation market on the basis of deployment mode?

- What is the breakup of the Japan smart factory automation market on the basis of industry vertical?

- What is the breakup of the Japan smart factory automation market on the basis of region?

- What are the various stages in the value chain of the Japan smart factory automation market?

- What are the key driving factors and challenges in the Japan smart factory automation?

- What is the structure of the Japan smart factory automation m\arket and who are the key players?

- What is the degree of competition in the Japan smart factory automation market?

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the Japan smart factory automation market from 2020-2034.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the Japan smart factory automation market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the Japan smart factory automation industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)