Mexico 3D Printing Market Size, Share, Trends and Forecast by Technology, Process, Material, Offering, Application, End-User, and Region, 2025-2033

Mexico 3D Printing Market Overview:

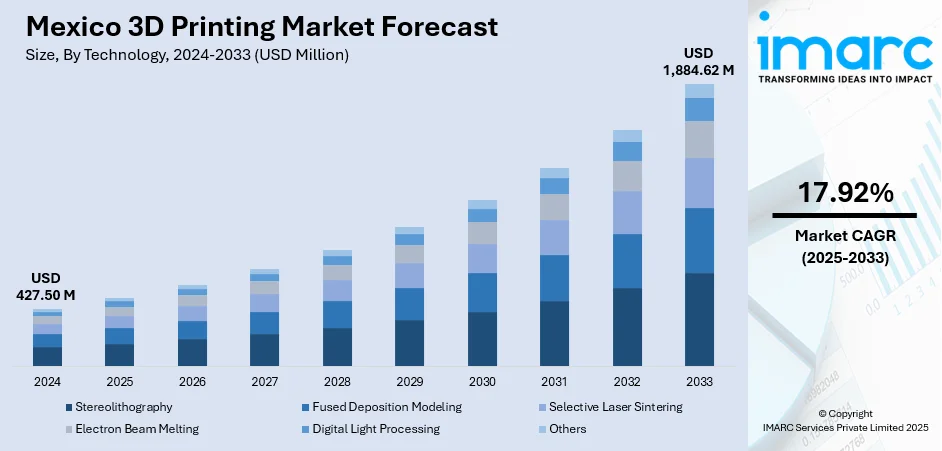

The Mexico 3D printing market size reached USD 427.50 Million in 2024. Looking forward, IMARC Group expects the market to reach USD 1,884.62 Million by 2033, exhibiting a growth rate (CAGR) of 17.92% during 2025-2033. The surging adoption of additive manufacturing across automotive, aerospace, and healthcare sectors for rapid prototyping and customized production, strong government support through tax incentives and research and development (R&D) funding, and ongoing technological advancements enhancing efficiency and material diversity are strengthening the market growth.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2024

|

|

Forecast Years

|

2025-2033

|

|

Historical Years

|

2019-2024

|

| Market Size in 2024 | USD 427.50 Million |

| Market Forecast in 2033 | USD 1,884.62 Million |

| Market Growth Rate 2025-2033 | 17.92% |

Mexico 3D Printing Market Trends:

Diversified Industrial Adoption Across Automotive, Aerospace, and Healthcare

Mexico’s 3D printing market is witnessing rapid uptake across multiple heavy-industry verticals, most notably automotive prototyping and spare-parts production, aerospace component fabrication, and healthcare device customization. OEMs in the automotive sector are leveraging additive manufacturing to reduce lead times on complex tooling and produce lightweight, topology-optimized parts. Aerospace firms are similarly deploying metal‐ and polymer-based printers for mission-critical components, cutting down certification cycles. Meanwhile, medical providers are adopting 3D-printed surgical guides and patient-specific implants, driving demand for biocompatible materials. This cross-sector diversification is creating a positive outlook for market expansion.

To get more information on this market, Request Sample

Supportive Government Initiatives

The Mexican government has enacted comprehensive policies under Plan Mexico to incentivize investment in advanced manufacturing technologies, including 3D printing. In January 2025, an executive order introduced accelerated tax incentives, allowing 100% immediate deduction of new fixed assets. These incentives are designed to position Mexico among the top ten global economies by stimulating nearshoring, dual training programs, and innovation in high-tech sectors. Additionally, the now-permanent Research & Development Tax Credit enables companies to recover wages for prototyping, filament costs, and integration efforts related to 3D printing R&D. Financial trade incentives and state-level support programs further reduce operational expenses, further propelling the market growth.

Mexico 3D Printing Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the region/country level for 2025-2033. Our report has categorized the market based on technology, process, material, offering, application, and end-user.

Technology Insights:

- Stereolithography

- Fused Deposition Modeling

- Selective Laser Sintering

- Electron Beam Melting

- Digital Light Processing

- Others

The report has provided a detailed breakup and analysis of the market based on the technology. This includes stereolithography, fused deposition modeling, selective laser sintering, electron beam melting, digital light processing, and others.

Process Insights:

- Binder Jetting

- Directed Energy Deposition

- Material Extrusion

- Material Jetting

- Powder Bed Fusion

- Sheet Lamination

- Vat Photopolymerization

A detailed breakup and analysis of the market based on the process have also been provided in the report. This includes binder jetting, directed energy deposition, material extrusion, material jetting, power bed fusion, sheet lamination, and vat photopolymerization.

Material Insights:

- Photopolymers

- Plastics

- Metals and Ceramics

- Others

The report has provided a detailed breakup and analysis of the market based on the material. This includes photopolymers, plastics, metals and ceramics, and others.

Offering Insights:

- Printer

- Material

- Software

- Service

A detailed breakup and analysis of the market based on the offering have also been provided in the report. This includes printer, material, software, and service.

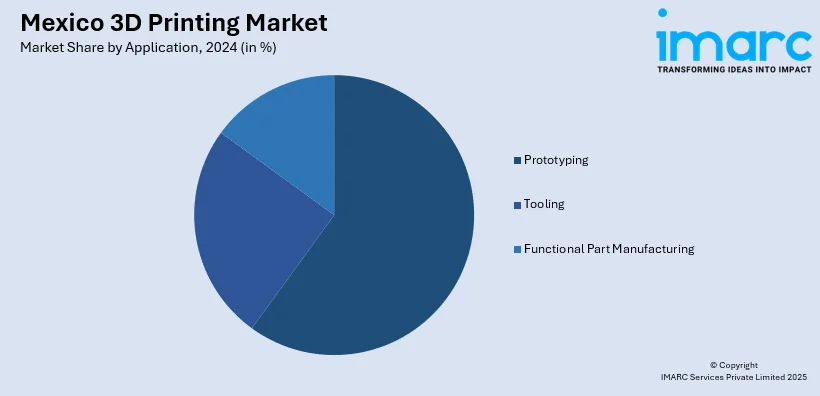

Application Insights:

- Prototyping

- Tooling

- Functional Part Manufacturing

The report has provided a detailed breakup and analysis of the market based on the application. This includes prototyping, tooling, and functional part manufacturing.

End-User Insights:

- Consumer Products

- Machinery

- Healthcare

- Aerospace

- Automobile

- Others

A detailed breakup and analysis of the market based on the end-user have also been provided in the report. This includes consumer products, machinery, healthcare, aerospace, automobile, and others.

Regional Insights:

- Northern Mexico

- Central Mexico

- Southern Mexico

- Others

The report has also provided a comprehensive analysis of all the major regional markets, which include Northern Mexico, Central Mexico, Southern Mexico, and others.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

Mexico 3D Printing Market News:

- May 2025: Sitres Latam, Alar, and Tecnológico de Monterrey collaborated to introduce Meltio’s wire-laser metal 3D printing technology in Mexico. Using wire-laser deposition, this product offers safer, cost-effective, and sustainable metal part production. With applications across defense, aerospace, and energy, this innovation enhances manufacturing flexibility and efficiency, marking a major step forward for industrial 3D printing in Mexico.

- July 2024: Eplus3D partnered with Mexico's Hi-Tec Group to introduce its Metal Powder Bed Fusion (MPBF) 3D printing technology. This collaboration aims to enhance precision manufacturing across sectors like aerospace, automotive, and energy by enabling efficient, on-demand production of complex metal parts.

Mexico 3D Printing Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2024 |

| Historical Period | 2019-2024 |

| Forecast Period | 2025-2033 |

| Units | Million USD |

| Scope of the Report |

Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Technologies Covered | Stereolithography, Fused Deposition Modeling, Selective Laser Sintering, Electron Beam Melting, Digital Light Processing, Others |

| Processes Covered | Binder Jetting, Directed Energy Deposition, Material Extrusion, Material Jetting, Power Bed Fusion, Sheet Lamination, Vat Photopolymerization |

| Materials Covered | Photopolymers, Plastics, Metals and Ceramics, Others |

| Offerings Covered | Printer, Material, Software, Service |

| Applications Covered | Prototyping, Tooling, Functional Part Manufacturing |

| End-Users Covered | Consumer Products, Machinery, Healthcare, Aerospace, Automobile, Others |

| Regions Covered | Northern Mexico, Central Mexico, Southern Mexico, Others |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the Mexico 3D printing market performed so far and how will it perform in the coming years?

- What is the breakup of the Mexico 3D printing market on the basis of technology?

- What is the breakup of the Mexico 3D printing market on the basis of process?

- What is the breakup of the Mexico 3D printing market on the basis of material?

- What is the breakup of the Mexico 3D printing market on the basis of offering?

- What is the breakup of the Mexico 3D printing market on the basis of application?

- What is the breakup of the Mexico 3D printing market on the basis of end-user?

- What is the breakup of the Mexico 3D printing market on the basis of region?

- What are the various stages in the value chain of the Mexico 3D printing market?

- What are the key driving factors and challenges in the Mexico 3D printing market?

- What is the structure of the Mexico 3D printing market and who are the key players?

- What is the degree of competition in the Mexico 3D printing market?

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the Mexico 3D printing market from 2019-2033.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the Mexico 3D printing market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the Mexico 3D printing industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)