Mexico Hydraulic Press Market Size, Share, Trends and Forecast by Type, Application, End-User, and Region, 2025-2033

Mexico Hydraulic Press Market Overview:

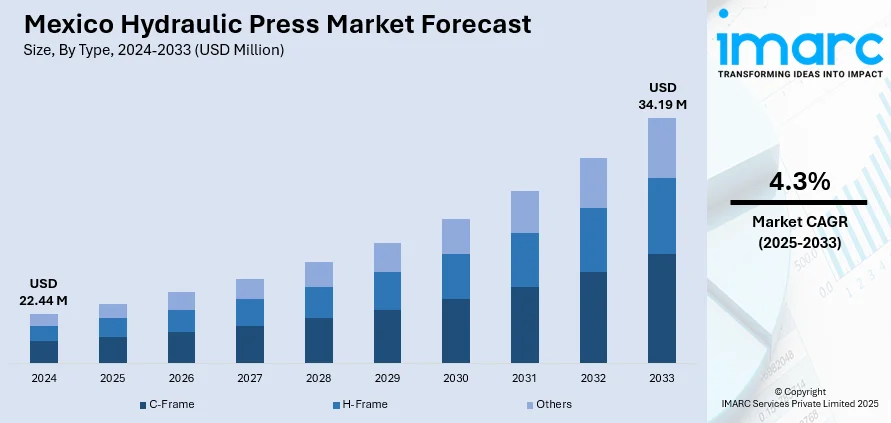

The Mexico hydraulic press market size reached USD 22.44 Million in 2024. Looking forward, IMARC Group expects the market to reach USD 34.19 Million by 2033, exhibiting a growth rate (CAGR) of 4.3% during 2025-2033. Growth in automotive and manufacturing industries, rising demand for metal forming processes, and increased investment in industrial automation are some of the factors contributing to Mexico hydraulic press market share. Government incentives for local production and expanding export opportunities across Latin America further support the market’s momentum in the country.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2024

|

|

Forecast Years

|

2025-2033

|

|

Historical Years

|

2019-2024

|

| Market Size in 2024 | USD 22.44 Million |

| Market Forecast in 2033 | USD 34.19 Million |

| Market Growth Rate 2025-2033 | 4.3% |

Mexico Hydraulic Press Market Trends:

Rising Local Support Infrastructure for Hydraulic Equipment

Mexico is witnessing increased investment in localized distribution networks to meet the growing demand for hydraulic components. With many manufacturers scaling operations in the region, there is a clear shift toward improving supply chain responsiveness and reducing equipment downtime. The focus is on ensuring quicker access to critical parts like fittings and connectors that support hydraulic presses and related machinery. This development enhances service quality for domestic manufacturers and international clients operating in Mexico. It also signals confidence in the country’s industrial expansion, especially in sectors such as automotive, metal forming, and machinery. The strengthening of local infrastructure is expected to play a key role in maintaining production continuity and supporting the broader growth of hydraulic press applications. These factors are intensifying the Mexico hydraulic press market growth. For example, in May 2024, Brennan Industries opened a new distribution facility in Mexico to support growing demand for hydraulic components. This move ensures faster access to fittings and uninterrupted supply for manufacturers expanding in the region. The facility strengthens local support for hydraulic machinery, including presses, by improving availability and responsiveness. Brennan’s investment aligns with Mexico’s expanding industrial base, reinforcing its role as a key market for hydraulic systems and components.

Expansion of Local Manufacturing Capabilities in Heavy-Duty Hydraulics

Mexico is emerging as a strategic base for hydraulic hose production to meet growing regional demand, especially in heavy-duty sectors. New manufacturing facilities are being established to serve critical industries like metal forming, where hydraulic presses play an essential role. By producing closer to end-users, companies can reduce lead times, improve parts availability, and enhance service for press equipment operators. This shift supports greater operational efficiency for manufacturers in North and Latin America. It also reflects rising confidence in Mexico’s industrial ecosystem, where localized production is now key to meeting the performance and delivery expectations of hydraulic press users in construction, agriculture, and machinery applications. For instance, in March 2024, Continental expanded its presence in the hydraulic sector with a new hydraulic hose plant in Mexico, driven by rising demand across heavy-duty applications. The facility would support key industries such as construction, agriculture, and metal forming, where hydraulic presses are widely used. This local production hub will improve lead times, strengthen aftermarket support, and position Continental to better serve press manufacturers and users across North and Latin America.

Mexico Hydraulic Press Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the country and regional levels for 2025-2033. Our report has categorized the market based on type, application, and end-user.

Type Insights:

- C-Frame

- H-Frame

- Others

The report has provided a detailed breakup and analysis of the market based on the type. This includes C-frame, H-frame, and others.

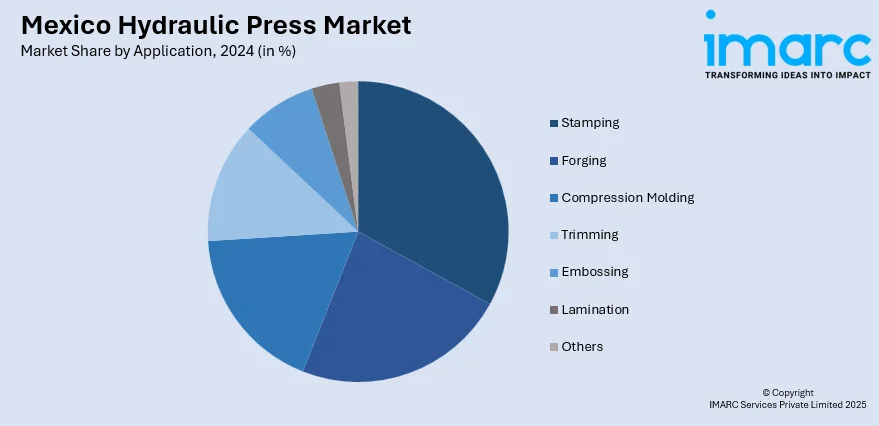

Application Insights:

- Stamping

- Forging

- Compression Molding

- Trimming

- Embossing

- Lamination

- Others

A detailed breakup and analysis of the market based on the application have also been provided in the report. This includes stamping, forging, compression molding, trimming, embossing, lamination, and others.

End-User Insights:

- Automotive

- Food and Beverage

- Metal Fabrication

- Manufacturing

- Others

A detailed breakup and analysis of the market based on the end-user have also been provided in the report. This includes automotive, food and beverage, metal fabrication, manufacturing, and others.

Regional Insights:

- Northern Mexico

- Central Mexico

- Southern Mexico

- Others

The report has also provided a comprehensive analysis of all the major regional markets, which include Northern Mexico, Central Mexico, Southern Mexico, and others.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

Mexico Hydraulic Press Market News:

- In March 2025, ENGEL opened a new manufacturing facility in Querétaro, Mexico, to enhance local production of industrial machinery, including hydraulic-based systems like the WINTEC t-win series. The expansion aims to reduce delivery times, support automation, and strengthen after-sales service across the Americas. This investment reflects growing industrial activity in Mexico, signaling increased demand for forming equipment such as hydraulic presses across automotive and general manufacturing sectors.

Mexico Hydraulic Press Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2024 |

| Historical Period | 2019-2024 |

| Forecast Period | 2025-2033 |

| Units | Million USD |

| Scope of the Report |

Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Types Covered | C-Frame, H-Frame, Others |

| Applications Covered | Stamping, Forging, Compression Molding, Trimming, Embossing, Lamination, Others |

| End-Users Covered | Automotive, Food and Beverage, Metal Fabrication, Manufacturing, Others |

| Regions Covered | Northern Mexico, Central Mexico, Southern Mexico, Others |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the Mexico hydraulic press market performed so far and how will it perform in the coming years?

- What is the breakup of the Mexico hydraulic press market on the basis of type?

- What is the breakup of the Mexico hydraulic press market on the basis of application?

- What is the breakup of the Mexico hydraulic press market on the basis of end-user?

- What is the breakup of the Mexico hydraulic press market on the basis of region?

- What are the various stages in the value chain of the Mexico hydraulic press market?

- What are the key driving factors and challenges in the Mexico hydraulic press market?

- What is the structure of the Mexico hydraulic press market and who are the key players?

- What is the degree of competition in the Mexico hydraulic press market?

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the Mexico hydraulic press market from 2019-2033.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the Mexico hydraulic press market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the Mexico hydraulic press industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)