Mexico Lubrication Systems Market Size, Share, Trends and Forecast by Type, Application, Process, and Region, 2025-2033

Mexico Lubrication Systems Market Overview:

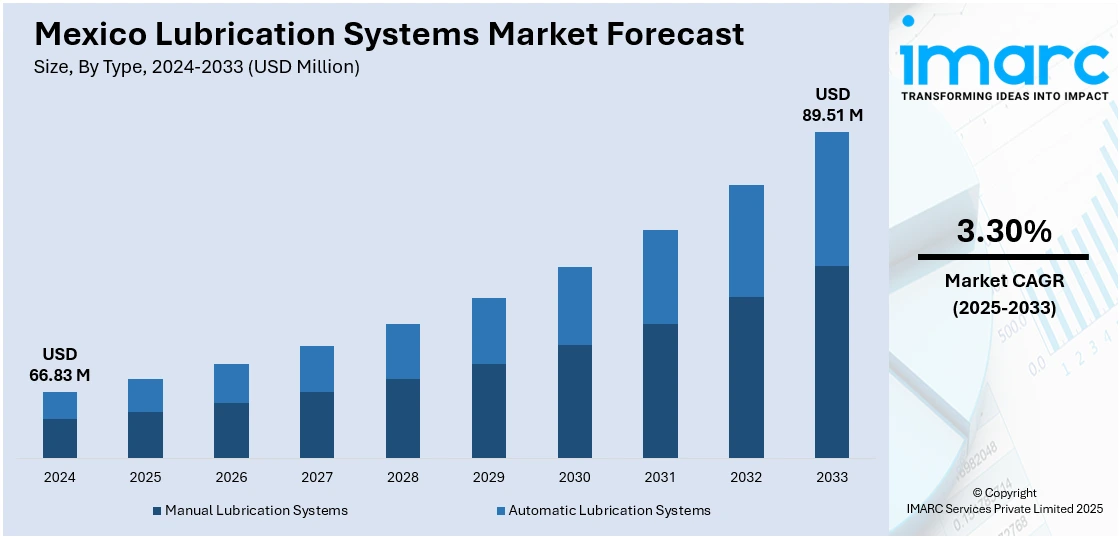

The Mexico lubrication systems market size reached USD 66.83 Million in 2024. Looking forward, IMARC Group expects the market to reach USD 89.51 Million by 2033, exhibiting a growth rate (CAGR) of 3.30% during 2025-2033. The market is driven by increasing demand across manufacturing, mining, automotive, and energy sectors. Technological advancements in automated lubrication solutions are improving operational efficiency and reducing maintenance downtime. Rising awareness of equipment longevity and sustainability further supports adoption. These dynamics collectively contribute to the expanding Mexico lubrication systems market share.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2024 |

|

Forecast Years

|

2025-2033

|

|

Historical Years

|

2019-2024

|

| Market Size in 2024 | USD 66.83 Million |

| Market Forecast in 2033 | USD 89.51 Million |

| Market Growth Rate 2025-2033 | 3.30% |

Mexico Lubrication Systems Market Trends:

Expanding Industrial and Manufacturing Base

Mexico's robust manufacturing sector, especially in automotive, aerospace, and electronics, is a significant driver for lubrication systems. The increasing number of assembly lines and production facilities creates a critical demand for effective lubrication solutions that maintain continuous operations and reduce equipment deterioration. Automated lubrication systems demonstrate increasing popularity because they provide accurate application while reducing accidental human errors. The pursuit of higher productivity while minimizing operational downtime creates an increasing need for advanced lubrication technologies. Government efforts to attract foreign direct investment in industrial development support the growing trend of adopting lubrication systems throughout the country's primary manufacturing areas.

Growth in the Mining and Energy Sectors

Mexico’s mining and energy sectors, which include oil and gas as well as renewable energy initiatives, require heavy-duty equipment operating under extreme conditions. These industries rely on lubrication systems to maintain machinery performance, extend service life, and prevent costly failures. The harsh environments and remote locations necessitate automated and centralized lubrication solutions for operational reliability and safety. With ongoing investments in mining exploration and energy infrastructure, including refineries and pipelines, the need for efficient and low-maintenance lubrication systems is becoming more prominent. As these sectors expand, equipment manufacturers and service providers are increasingly integrating lubrication systems into their solutions to support Mexico’s energy and resource-driven economy.

Rising Focus on Operational Efficiency and Maintenance Cost Reduction

Businesses in Mexico are placing greater emphasis on minimizing unplanned downtime and reducing maintenance costs, which is driving the Mexico lubrication systems market growth. Lubrication systems play a critical role by ensuring continuous, consistent lubrication, which improves equipment efficiency and minimizes friction and wear. Automated systems also reduce the need for manual intervention, lowering labor costs and safety risks. Industries such as food processing, packaging, and logistics particularly benefit from systems that enhance productivity without interrupting operations. The shift toward predictive maintenance practices is also encouraging companies to integrate lubrication systems with IoT-enabled sensors, providing real-time data on machine health and performance. This trend supports a broader movement toward digital transformation and lean operational strategies across industrial sectors in Mexico.

Mexico Lubrication Systems Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the country and regional levels for 2025-2033. Our report has categorized the market based on type, application, and process.

Type Insights:

- Manual Lubrication Systems

- Automatic Lubrication Systems

- Single-line Lubrication Systems

- Dual-line Lubrication Systems

- Multi-line Lubrication Systems

- Series Progressive

- Circulating Oil

- Oil and Air

The report has provided a detailed breakup and analysis of the market based on the type. This includes manual lubrication systems and automatic lubrication systems (single-line lubrication systems, dual-line lubrication systems, multi-line lubrication systems, series progressive, circulating oil, and oil and air).

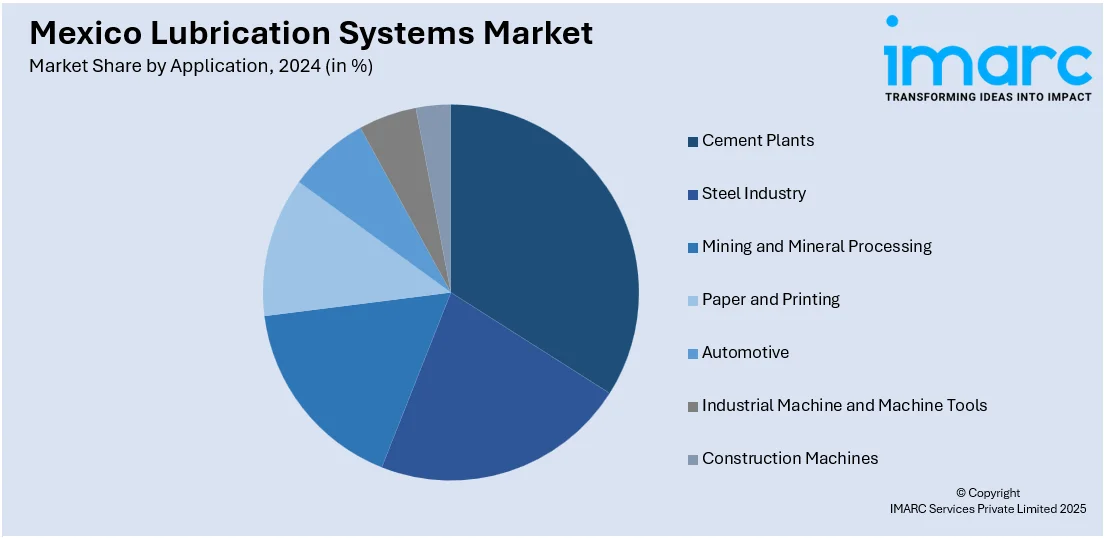

Application Insights:

- Cement Plants

- Steel Industry

- Mining and Mineral Processing

- Paper and Printing

- Automotive

- Industrial Machine and Machine Tools

- Construction Machines

A detailed breakup and analysis of the market based on the application have also been provided in the report. This includes cement plants, steel industry, mining and mineral processing, paper and printing, automotive, industrial machine and machine tools, and construction machines.

Process Insights:

- Dry Sump Lubrication

- Wet Sump Lubrication

A detailed breakup and analysis of the market based on the process have also been provided in the report. This includes dry sump lubrication and wet sump lubrication.

Regional Insights:

- Northern Mexico

- Central Mexico

- Southern Mexico

- Others

The report has also provided a comprehensive analysis of all the major regional markets, which include Northern Mexico, Central Mexico, Southern Mexico, and others.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

Mexico Lubrication Systems Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2024 |

| Historical Period | 2019-2024 |

| Forecast Period | 2025-2033 |

| Units | Million USD |

| Scope of the Report | Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Types Covered |

|

| Applications Covered | Cement Plants, Steel Industry, Mining and Mineral Processing, Paper and Printing, Automotive, Industrial Machine and Machine Tools, Construction Machines |

| Processes Covered | Dry Sump Lubrication, Wet Sump Lubrication |

| Regions Covered | Northern Mexico, Central Mexico, Southern Mexico, Others |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the Mexico lubrication systems market performed so far and how will it perform in the coming years?

- What is the breakup of the Mexico lubrication systems market based on type?

- What is the breakup of the Mexico lubrication systems market on the basis of application?

- What is the breakup of the Mexico lubrication systems market on the basis of process?

- What is the breakup of the Mexico lubrication systems market on the basis of region?

- What are the various stages in the value chain of the Mexico lubrication systems market?

- What are the key driving factors and challenges in the Mexico lubrication systems market?

- What is the structure of the Mexico lubrication systems market and who are the key players?

- What is the degree of competition in the Mexico lubrication systems market?

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the Mexico lubrication systems market from 2019-2033.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the Mexico lubrication systems market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the Mexico lubrication systems industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)