Mexico Smart Conveyor Systems Market Size, Share, Trends and Forecast by Component, Product Type, Technology, Automation Level, And Industry Vertical, and Region, 2025-2033

Mexico Smart Conveyor Systems Market Overview:

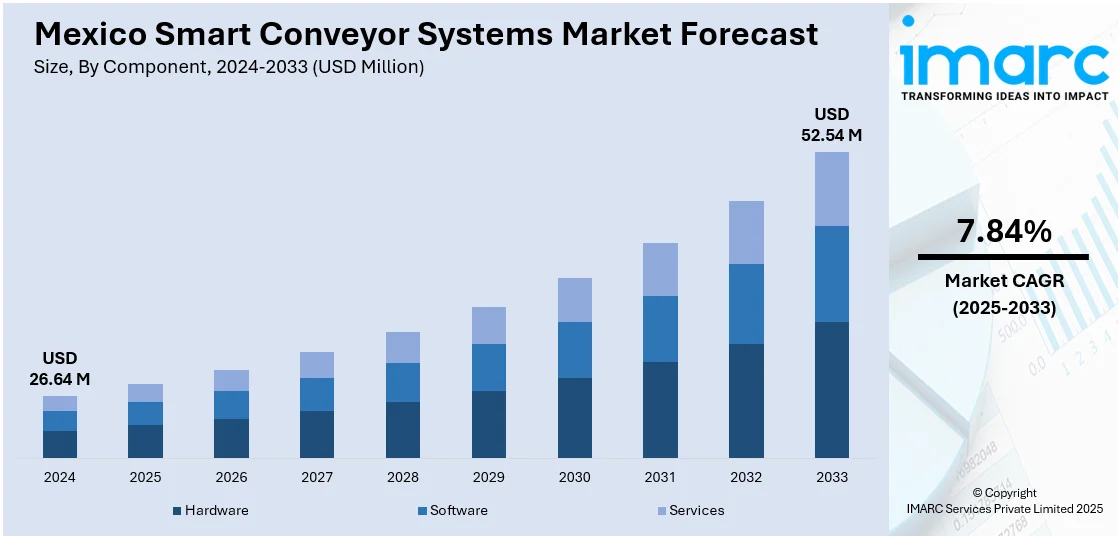

The Mexico smart conveyor systems market size reached USD 26.64 Million in 2024. Looking forward, IMARC Group expects the market to reach USD 52.54 Million by 2033, exhibiting a growth rate (CAGR) of 7.84% during 2025-2033. The market is fueled by the adoption of Industrial Internet of Things (IIoT) technologies to monitor operations in real-time, greater use of completely automated material handling systems to enhance workflow efficiency, and the use of artificial intelligence (AI) and machine learning (ML) for predictive maintenance and process improvement. All these innovations are making logistics, manufacturing, and retail more efficient through higher throughput, less system downtime, and supporting data-driven decision-making. Mexico smart conveyor systems market share is thus witnessing consistent growth across industrial sectors as a result.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2024 |

|

Forecast Years

|

2025-2033

|

|

Historical Years

|

2019-2024

|

| Market Size in 2024 | USD 26.64 Million |

| Market Forecast in 2033 | USD 52.54 Million |

| Market Growth Rate 2025-2033 | 7.84% |

Mexico Smart Conveyor Systems Market Trends:

Integration of Industrial Internet of Things (IIoT)

The implementation of Industrial Internet of Things (IIoT) technologies is greatly influencing the future of conveyor systems in Mexico. Industries in various sectors like automotive, food processing, and logistics are increasingly turning to IIoT to increase real-time monitoring, predictive maintenance, and transparency of operations. For instance, in October 2023, Balluff opened a €50M smart factory in Aguascalientes, Mexico, amplifying regional smart conveyor systems using state-of-the-art automation and sensor technology for efficient and resilient supply chains. Moreover, conveyor systems equipped with IIoT have the benefit of collecting an enormous amount of data through in-built sensors and sending it to centralized systems for analysis. This integration assists in detecting inefficiencies, tracking belt performance, and maintaining timely maintenance without stopping production lines. Furthermore, with the use of IIoT, business organizations can enhance traceability and regulatory compliance. The far-reaching adaptation of IIoT is not just increasing system reliability but also empowering intelligent decision-making processes. As industrial processes endeavor to be increasingly automated and optimized based on data, the implementation of IIoT technologies serves as a main trend supporting the Mexico smart conveyor systems expansion.

Growing Deployment of Fully Automated Material Handling Solutions

One of the key trends fueling innovation in Mexico conveyor systems is the growing movement towards the use of fully automated material handling systems. For example, in March 2024, Locus Robotics collaborated with GEODIS to implement Autonomous Mobile Robots in Mexico, adding logistics automation and joining Mexico's increasing trend toward smart conveyor systems in industrial settings. Furthermore, automation is being quick to adopt as it helps enable large-scale production, distribution, and warehousing activities. Such fully automated conveyor systems are engineered with modern robotics, programmable logic controllers (PLCs), and adaptive software that enables smooth handling of extensive ranges of different kinds of goods with minimum human interaction. In applications where operational speed, accuracy, and throughput are most important, these systems minimize delay, remove the possibility of manual error, and maximize overall efficiency. Additionally, completely automated systems provide scalability to expand in the future, which allows companies to match infrastructure to long-term expansion. Their constant operation over several shifts also further supports lean manufacturing goals. With the increased demand for fast logistics and prompt deliveries, this trend also represents a broader move toward smarter infrastructure that optimizes productivity in Mexico's industrial and business scene.

Use of Artificial Intelligence (AI) and Machine Learning (ML) to Optimize Conveyors

AI and ML technologies are performing a revolutionary function to enhance Mexico smart conveyor systems market growth. These technologies facilitate dynamic decision-making based on real-time operating data and past performance trends. AI-based conveyors have the capability to dynamically adjust speed, balance loads, and recognize anomalies that could point to potential system breakdowns. Using predictive analytics, organizations can schedule maintenance better, reduce unplanned downtime, and enhance system lifespan. Moreover, machine learning algorithms are employed to improve object detection and sorting accuracy, especially useful in high-throughput sectors like logistics and retail. These systems' ability to continuously learn enables improvement of performance continuously, making them suitable for intricate and dynamic operations. With increasingly accessible and affordable AI and ML, their use in conveyor systems will be widespread, propelling technological advancement and intelligent automation techniques in Mexico's manufacturing and supply chain industries.

Mexico Smart Conveyor Systems Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the country and regional levels for 2025-2033. Our report has categorized the market based on component, product type, technology, automation level, and industry vertical.

Component Insights:

- Hardware

- Software

- Services

The report has provided a detailed breakup and analysis of the market based on the component. This includes hardware, software, and services.

Product Type Insights:

- Belt Conveyors

- Roller Conveyors

- Overhead Conveyors

- Pallet Conveyors

- Sortation Systems

The report has provided a detailed breakup and analysis of the market based on the product type. This includes belt conveyors, roller conveyors, overhead conveyors, pallet conveyors, and sortation systems.

Technology Insights:

- IoT-Enabled Conveyors

- AI-Driven Systems

- Robotic Integration

- RFID and Barcode Scanning

A detailed breakup and analysis of the market based on the technology have also been provided in the report. This includes IoT-enabled conveyors, AI-driven systems, robotic integration, and RFID and barcode scanning.

Automation Level Insights:

- Semi-Automated Conveyor Systems

- Fully Automated Conveyor Systems

The report has provided a detailed breakup and analysis of the market based on the automation level. This includes semi-automated conveyor systems, and fully automated conveyor systems.

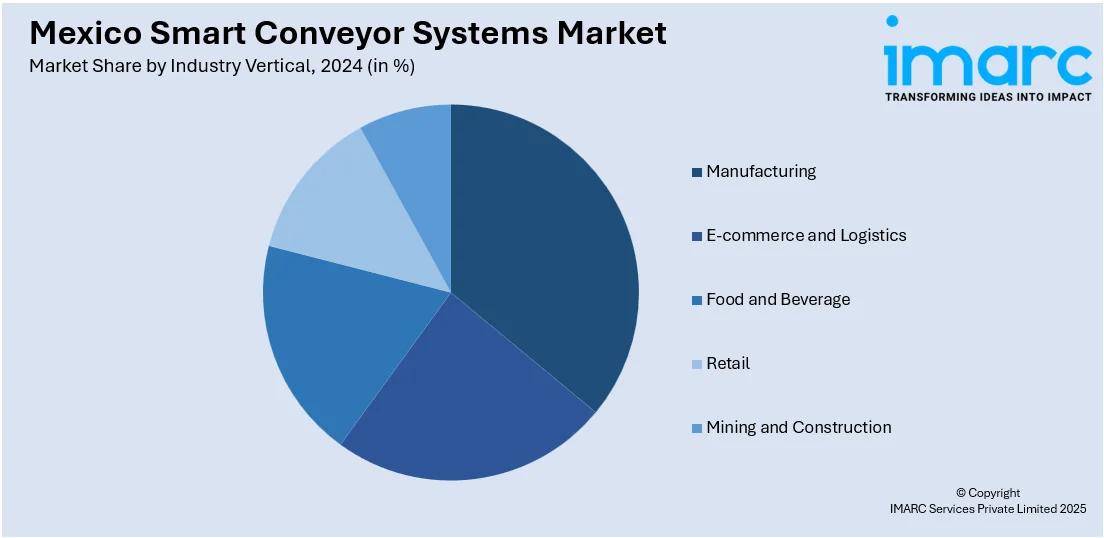

Industry Vertical Insights:

- Manufacturing

- E-commerce and Logistics

- Food and Beverage

- Retail

- Mining and Construction

A detailed breakup and analysis of the market based on the industry vertical have also been provided in the report. This includes manufacturing, e-commerce and logistics, food and beverage, retail, mining and construction.

Regional Insights:

- Northern Mexico

- Central Mexico

- Southern Mexico

- Others

The report has also provided a comprehensive analysis of all the major regional markets, which include Northern Mexico, Central Mexico, Southern Mexico, and Others.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

Mexico Smart Conveyor Systems Market News:

- In May 2024, Coesia will introduce cutting-edge automation solutions at EXPO PACK México 2024. Highlighted products are FlexLink's space-efficient Compact Spiral Elevator and Enflex's F-17 packaging machine, which is meant to improve efficiency and sustainability, providing optimized conveyor systems for Mexico's expanding industrial base.

- In March 2024, Symbotic further established itself in Mexico through the deployment of advanced warehouse automation solutions for Walmex. The integration, with AI-based robotics and advanced smart conveyor technologies, is intended to streamline logistics operations, enhance efficiency, and strengthen Mexico as a central component in the transforming global supply chain.

Mexico Smart Conveyor Systems Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2024 |

| Historical Period | 2019-2024 |

| Forecast Period | 2025-2033 |

| Units | Million USD |

| Scope of the Report | Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Components Covered | Hardware, Software, Services |

| Product Types Covered | Belt Conveyors, Roller Conveyors, Overhead Conveyors, Pallet Conveyors, Sortation Systems |

| Technologies Covered | IoT-Enabled Conveyors, AI-Driven Systems, Robotic Integration, RFID and Barcode Scanning |

| Automation Levels Covered | Semi-Automated Conveyor Systems, Fully Automated Conveyor Systems |

| Industry Verticals Covered | Manufacturing, E-commerce and Logistics, Food and Beverage, Retail, Mining and Construction |

| Regions Covered | Northern Mexico, Central Mexico, Southern Mexico, Others |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the Mexico smart conveyor systems market performed so far and how will it perform in the coming years?

- What is the breakup of the Mexico smart conveyor systems market on the basis of component?

- What is the breakup of the Mexico smart conveyor systems market on the basis of product type?

- What is the breakup of the Mexico smart conveyor systems market on the basis of technology?

- What is the breakup of the Mexico smart conveyor systems market on the basis of automation level?

- What is the breakup of the Mexico smart conveyor systems market on the basis of industry vertical?

- What is the breakup of the Mexico smart conveyor systems market on the basis of region?

- What are the various stages in the value chain of the Mexico smart conveyor systems market?

- What are the key driving factors and challenges in the Mexico smart conveyor systems?

- What is the structure of the Mexico smart conveyor systems market and who are the key players?

- What is the degree of competition in the Mexico smart conveyor systems market?

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the Mexico smart conveyor systems market from 2019-2033

- The research report provides the latest information on the market drivers, challenges, and opportunities in the Mexico smart conveyor systems market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the Mexico smart conveyor systems industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)