Mexico Thermal Processing Equipment Market Size, Share, Trends and Forecast by Equipment Type, Process Type, Heating Source, Automation Level, End Use Industry, and Region, 2025-2033

Mexico Thermal Processing Equipment Market Overview:

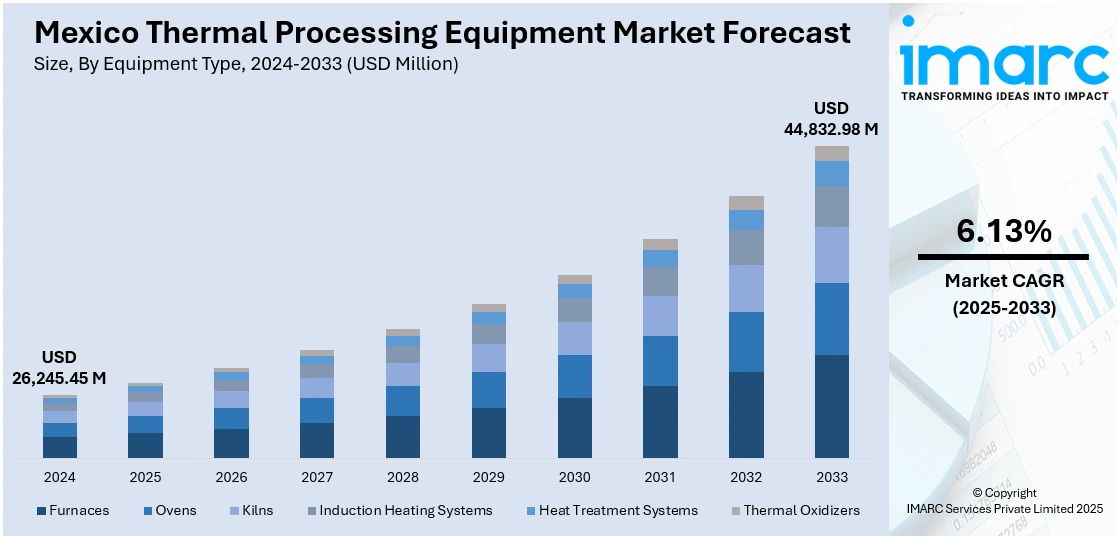

The Mexico thermal processing equipment market size reached USD 26,245.45 Million in 2024. Looking forward, IMARC Group expects the market to reach USD 44,832.98 Million by 2033, exhibiting a growth rate (CAGR) of 6.13% during 2025-2033. The market is driven by rising industrial demand, particularly in food processing, automotive, and pharmaceuticals. Stricter food safety regulations, energy efficiency requirements, and the adoption of automation are key growth factors. Additionally, government support for sustainable manufacturing and the expansion of Industry 4.0 technologies are expanding Mexico thermal processing equipment market share, encouraging businesses to invest in advanced thermal processing solutions.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2024 |

|

Forecast Years

|

2025-2033

|

|

Historical Years

|

2019-2024

|

| Market Size in 2024 | USD 26,245.45 Million |

| Market Forecast in 2033 | USD 44,832.98 Million |

| Market Growth Rate 2025-2033 | 6.13% |

Mexico Thermal Processing Equipment Market Trends:

Increasing Demand for Energy-Efficient Thermal Processing Equipment

The market is witnessing a growing demand for energy-efficient solutions, driven by rising energy costs and stricter environmental regulations. In 2023, the total energy consumption of Mexico amounted to 8.45 exajoules and was fueled chiefly by oil (45.4%) and gas (41.5%). 374.62 TWh were generated through electricity, with fossil fuels contributing 80%. Proven reserves in Mexico for oil amount to 5.978 billion barrels and for natural gas amount to 12.297 Tcf, making the nation the third largest in Latin America in oil potential. This tremendous need for fuel and energy infrastructure provides significant growth opportunities for the thermal processing equipment market in both industrial and energy markets across the country. Industries such as food processing, chemicals, and pharmaceuticals are adopting advanced thermal systems that minimize energy consumption while maintaining high performance. Technologies including heat recovery systems, improved insulation, and automated temperature controls are gaining traction as companies seek to reduce operational costs and carbon footprints. Additionally, government incentives for sustainable manufacturing practices are encouraging businesses to invest in eco-friendly thermal processing equipment. Manufacturers are responding by developing innovative, energy-saving designs that comply with international efficiency standards. This trend is expected to accelerate as more Mexican industries prioritize sustainability, making energy efficiency a key competitive factor in the thermal processing equipment market.

Growth in Automation and Smart Thermal Processing Systems

Automation and smart technologies are transforming Mexico’s market, enhancing precision, productivity, and safety. With a global use of factory robots of 4.28 million units in 2023, Mexico contributed 5,832 installations, 70% of which came from the automotive sector. Industrial automation in Mexico has been resilient and in line with cyclical behavior, even with a 3% drop in total installations. With this continued growth, there is a growing demand for monitoring systems to enable automation in the automotive and machinery sectors. Industries are increasingly integrating IoT-enabled devices, AI-based controls, and real-time monitoring systems to optimize thermal processes. Therefore, this is further propelling the Mexico thermal processing equipment market growth. Automated equipment reduces human error, ensures consistent product quality, and improves operational efficiency, making it ideal for sectors such as automotive, aerospace, and food production. The rise of Industry 4.0 is further driving the adoption of smart thermal systems that offer predictive maintenance and remote diagnostics, reducing downtime and maintenance costs. As Mexican manufacturers modernize their facilities, the demand for advanced, automated thermal processing solutions is expected to grow significantly. This trend aligns with global industrial advancements, positioning Mexico as a competitive player in smart manufacturing technologies.

Mexico Thermal Processing Equipment Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the country and regional levels for 2025-2033. Our report has categorized the market based on equipment type, process type, heating source, automation level, and end use industry.

Equipment Type Insights:

- Furnaces

- Ovens

- Kilns

- Induction Heating Systems

- Heat Treatment Systems

- Thermal Oxidizers

The report has provided a detailed breakup and analysis of the market based on the equipment type. This includes furnaces, ovens, kilns, induction heating systems, heat treatment systems, and thermal oxidizers.

Process Type Insights:

- Heat Treatment

- Annealing

- Hardening and Tempering

- Sintering

- Drying and Curing

- Calcination

A detailed breakup and analysis of the market based on the process type have also been provided in the report. This includes heat treatment, annealing, hardening and tempering, sintering, drying and curing, and calcination.

Heating Source Insights:

- Electric Thermal Processing

- Gas-Fired Systems

- Infrared and Microwave Heating

- Induction Heating

The report has provided a detailed breakup and analysis of the market based on the heating source. This includes electric thermal processing, gas-fired systems, infrared and microwave heating, and induction heating.

Automation Level Insights:

- Manual Thermal Processing Equipment

- Semi-Automated Systems

- Fully Automated Systems

A detailed breakup and analysis of the market based on the automation level have also been provided in the report. This includes manual thermal processing equipment, semi-automated systems, and fully automated systems.

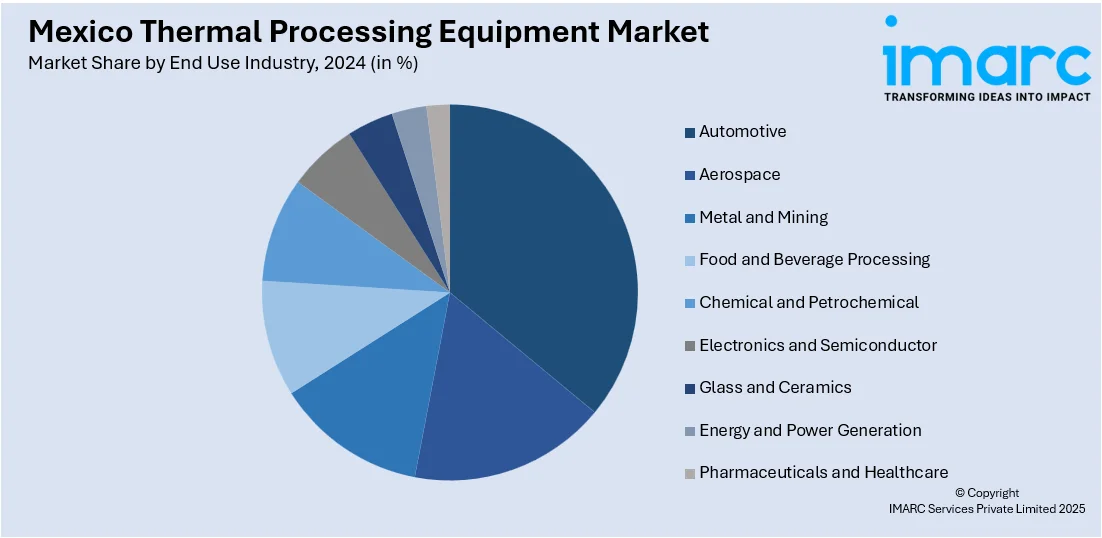

End Use Industry Insights:

- Automotive

- Aerospace

- Metal and Mining

- Food and Beverage Processing

- Chemical and Petrochemical

- Electronics and Semiconductor

- Glass and Ceramics

- Energy and Power Generation

- Pharmaceuticals and Healthcare

The report has provided a detailed breakup and analysis of the market based on the end use industry. This includes automotive, aerospace, metal and mining, food and beverage processing, chemical and petrochemical, electronics and semiconductor, glass and ceramics, energy and power generation, and pharmaceuticals and healthcare.

Regional Insights:

- Northern Mexico

- Central Mexico

- Southern Mexico

- Others

The report has also provided a comprehensive analysis of all the major regional markets, which include Northern Mexico, Central Mexico, Southern Mexico, and Others.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

Mexico Thermal Processing Equipment Market News:

- November 04, 2024: Godrej & Boyce supplied over 20 advanced process equipment units, including high-pressure reactors and large Chrome Moly Vanadium Steel columns, to two Mexican refineries. These thermal processing systems are designed for superior strength and corrosion resistance, enabling crucial upgrades in Mexico's refining sector. With 70% of its business coming from exports, the company is establishing itself in the Americas, thus strengthening India's global position within high-performance thermal processing equipment.

Mexico Thermal Processing Equipment Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2024 |

| Historical Period | 2019-2024 |

| Forecast Period | 2025-2033 |

| Units | Million USD |

| Scope of the Report |

Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Equipment Types Covered | Furnaces, Ovens, Kilns, Induction Heating Systems, Heat Treatment Systems, Thermal Oxidizers |

| Process Types Covered | Heat Treatment, Annealing, Hardening and Tempering, Sintering, Drying and Curing, Calcination |

| Heating Sources Covered | Electric Thermal Processing, Gas-Fired Systems, Infrared and Microwave Heating, Induction Heating |

| Automation Levels Covered | Manual Thermal Processing Equipment, Semi-Automated Systems, Fully Automated Systems |

| End Use Industries Covered | Automotive, Aerospace, Metal and Mining, Food and Beverage Processing, Chemical and Petrochemical, Electronics and Semiconductor, Glass and Ceramics, Energy and Power Generation, Pharmaceuticals and Healthcare |

| Regions Covered | Northern Mexico, Central Mexico, Southern Mexico, Others |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the Mexico thermal processing equipment market performed so far and how will it perform in the coming years?

- What is the breakup of the Mexico thermal processing equipment market on the basis of equipment type?

- What is the breakup of the Mexico thermal processing equipment market on the basis of process type?

- What is the breakup of the Mexico thermal processing equipment market on the basis of heating source?

- What is the breakup of the Mexico thermal processing equipment market on the basis of automation level?

- What is the breakup of the Mexico thermal processing equipment market on the basis of end use industry?

- What is the breakup of the Mexico thermal processing equipment market on the basis of region?

- What are the various stages in the value chain of the Mexico thermal processing equipment market?

- What are the key driving factors and challenges in the Mexico thermal processing equipment market?

- What is the structure of the Mexico thermal processing equipment market and who are the key players?

- What is the degree of competition in the Mexico thermal processing equipment market?

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the Mexico thermal processing equipment market from 2019-2033.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the Mexico thermal processing equipment market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the Mexico thermal processing equipment industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)