Philippines Conveyor Belt Market Size, Share, Trends and Forecast by Type, End Use, and Region, 2026-2034

Philippines Conveyor Belt Market Summary:

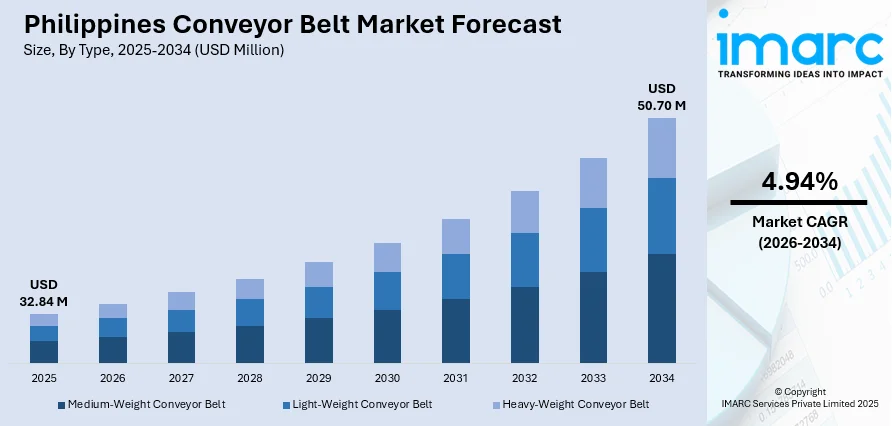

The Philippines conveyor belt market size was valued at USD 32.84 Million in 2025 and is projected to reach USD 50.70 Million by 2034, growing at a compound annual growth rate of 4.94% from 2026-2034.

The Philippines conveyor belt market is experiencing steady expansion driven by the country's robust industrial modernization initiatives and infrastructure development programs. Increasing investments in mining operations, manufacturing facilities, and logistics infrastructure are fueling demand for efficient material handling solutions across the archipelago. The market benefits from the government's Build Better More infrastructure program and rising automation adoption in key industries including cement production, food processing, and e-commerce fulfillment centers.

Key Takeaways and Insights:

-

By Type: Medium-weight conveyor belt dominates the market with a share of 56.95% in 2025, driven by versatility across manufacturing, logistics, and food processing applications requiring moderate load capacity.

-

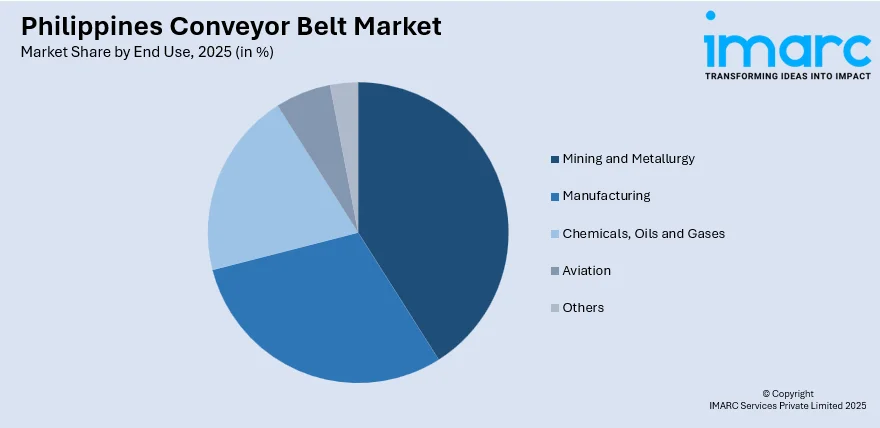

By End Use: Mining and metallurgy leads the market with a share of 40.92% in 2025, supported by the Philippines' position as the world's second-largest nickel producer and expanding mineral extraction activities.

-

By Region: Luzon represents the largest segment with a market share of 64% in 2025, attributed to Metro Manila's industrial concentration and the region's dominant manufacturing and logistics infrastructure.

-

Key Players: The Philippines conveyor belt market exhibits a competitive landscape characterized by the presence of both international manufacturers and regional suppliers. Leading players focus on product innovation, customization capabilities, and after-sales service networks to maintain market positioning across diverse industrial applications.

To get more information on this market Request Sample

The Philippines conveyor belt market demonstrates sustained growth momentum underpinned by the country's strategic industrial development agenda and infrastructure modernization programs. The market is primarily driven by expanding mining operations, manufacturing sector growth, and the rapid expansion of e-commerce logistics infrastructure across the archipelago. Government infrastructure investments through the Build Better More program are creating substantial demand for conveyor systems in cement production and construction material handling applications. In July 2024, Taiheiyo Cement Philippines invested around US$140 Million in jetty and marine belt conveyor project at its San Fernando, Cebu facility, representing significant investment in industrial conveyor infrastructure linking the cement plant to the coast for improved logistics efficiency. The market is further supported by rising adoption of smart conveyor technologies incorporating sensors, automation controls, and predictive maintenance capabilities that enhance operational efficiency across manufacturing and logistics facilities throughout the Philippines.

Philippines Conveyor Belt Market Trends:

Integration of AI and IoT Technologies in Conveyor Systems

The Philippines conveyor belt market is witnessing accelerating adoption of artificial intelligence and Internet of Things technologies across industrial applications. AI-powered systems analyze real-time data from conveyor components, calculating optimal speed, routing, and loading patterns to maximize throughput while minimizing energy consumption. Machine learning algorithms process sensor data tracking temperature, vibration, and wear patterns, enabling predictive maintenance capabilities that reduce equipment downtime. These smart technologies are transforming material handling operations by providing actionable insights for operational optimization, enhancing system reliability, and extending equipment lifespan across manufacturing and logistics facilities throughout the archipelago.

Expansion of E-commerce Logistics and Warehouse Automation

The rapid growth of e-commerce in the Philippines is driving significant demand for conveyor systems in fulfillment centers and distribution hubs. Conveyor belts maximize labor and space efficiency throughout logistics facilities by facilitating quicker sorting, packing, and shipping processes. Competition among e-commerce players intensifies around delivery speed and accuracy, making efficient material handling a critical competitive differentiator. In 2024, warehouse storage demand in the Philippines reached approximately 1.37 million square meters, nearly doubling year-over-year, reflecting growing requirements from logistics providers and e-commerce players investing in automated material handling infrastructure.

Development of Advanced Materials and Customized Belt Solutions

Manufacturers in the Philippines conveyor belt market are progressively investing in innovative materials and tailored designs to improve efficiency, longevity, and durability. Advancements include heat-resistant and chemical-resistant composites, flame-resistant rubbers, and environmentally friendly synthetic materials enhancing operational reliability while lowering energy consumption. Customization is becoming increasingly important as sectors including mining, food processing, and pharmaceuticals require belts tailored for specific applications capable of withstanding varying temperature, load, and sanitation requirements. These customized solutions guarantee operational precision while reducing maintenance expenses and equipment downtime across diverse industrial applications.

Market Outlook 2026-2034:

The Philippines conveyor belt market outlook remains positive through the forecast period, supported by sustained government infrastructure spending and industrial modernization initiatives. The Luzon Economic Corridor initiative, launched through trilateral cooperation between the Philippines, United States, and Japan, is expected to drive significant investment in manufacturing infrastructure and logistics connectivity across key industrial zones. Continued expansion of mining operations, cement production facilities, and e-commerce fulfilment centers will further sustain demand for efficient material handling solutions throughout the archipelago. The market generated a revenue of USD 32.84 Million in 2025 and is projected to reach a revenue of USD 50.70 Million by 2034, growing at a compound annual growth rate of 4.94% from 2026-2034.

Philippines Conveyor Belt Market Report Segmentation:

| Segment Category | Leading Segment | Market Share |

|---|---|---|

| Type | Medium-Weight Conveyor Belt | 56.95% |

| End Use | Mining and Metallurgy | 40.92% |

| Region | Luzon | 64% |

Type Insights:

- Medium-Weight Conveyor Belt

- Light-Weight Conveyor Belt

- Heavy-Weight Conveyor Belt

The medium-weight conveyor belt dominates with a market share of 56.95% of the total Philippines conveyor belt market in 2025.

Medium-weight conveyor belts have established market leadership owing to their versatility across manufacturing, logistics, and food processing applications requiring moderate load capacity and operational flexibility. These conveyor systems offer an optimal balance between durability and cost-effectiveness, making them suitable for diverse industrial environments throughout the Philippines. The Philippine industrial automation market is reflecting programmable automation representing the largest segment, indicating strong demand for automated material handling solutions including medium-weight conveyor systems.

The segment benefits from widespread adoption in e-commerce fulfillment centers, food and beverage manufacturing facilities, and pharmaceutical production environments where hygienic material handling requirements are paramount. Medium-weight belts accommodate various product types while maintaining consistent throughput rates essential for meeting operational targets. The Philippines food and beverage market is also expanding, with food processing manufacturers increasingly investing in conveyor automation to enhance production efficiency and meet growing domestic consumption demands.

End Use Insights:

Access the comprehensive market breakdown Request Sample

- Mining and Metallurgy

- Manufacturing

- Chemicals, Oils and Gases

- Aviation

- Others

The mining and metallurgy leads with a share of 40.92% of the total Philippines conveyor belt market in 2025.

Mining and metallurgy applications dominate conveyor belt demand in the Philippines, driven by the country's substantial mineral resources and expanding extraction activities. Conveyor systems are essential for transporting ore, coal, and processed materials across mining operations, reducing manual handling while improving operational efficiency and workplace safety. The Philippines possesses significant untapped deposits of copper, gold, nickel, and other critical minerals, positioning the mining sector as a primary driver of conveyor belt demand.

The segment is further supported by government initiatives promoting responsible mining and mineral processing to support the global energy transition toward renewable energy technologies. Mining operations require specialized conveyor belts capable of withstanding abrasive materials, extreme temperatures, and continuous heavy-load applications. The mining sector's economic significance continues driving investment in material handling infrastructure including advanced conveyor systems designed for improved operational productivity, reduced maintenance requirements, and enhanced worker safety across extraction and processing facilities.

Regional Insights:

- Luzon

- Visayas

- Mindanao

Luzon exhibits clear dominance with a 64% share of the total Philippines conveyor belt market in 2025.

Luzon's market dominance reflects the region's concentration of industrial activity, manufacturing facilities, and logistics infrastructure serving the Philippine economy. Metro Manila and the surrounding Calabarzon and Central Luzon regions host numerous economic zones and industrial parks requiring efficient material handling solutions. The Bases Conversion and Development Authority approved PHP 53.5 Billion in investments across its properties, including Clark and Subic, in the first seven months of 2025, unlocking approximately 7,000 jobs.

The region benefits from superior transportation networks, skilled labor availability, and proximity to major ports facilitating import of conveyor components and export of manufactured goods. Luzon accounts for the majority of national cement demand, driving conveyor belt installations in cement production and distribution facilities. Industrial park developers continue expanding land supply across Luzon, with Central Luzon provinces experiencing significant growth in warehousing and light industry developments supporting increased demand for material handling equipment and conveyor systems.

Market Dynamics:

Growth Drivers:

Why is the Philippines Conveyor Belt Market Growing?

Expansion of Mining Activities and Mineral Processing Infrastructure

The Philippines conveyor belt market is experiencing significant growth driven by expanding mining operations and investments in mineral processing infrastructure across the archipelago. The government's renewed focus on responsible mining to support global energy transition requirements is attracting substantial investments in extraction and processing facilities requiring efficient material handling systems. During the October 2024 Presidential Mineral Industry Environmental Award ceremony, President Marcos underscored the mining industry's crucial role in national development, emphasizing alignment of economic growth with environmental sustainability.

Government Infrastructure Programs and Industrial Development Initiatives

The Philippine government's Build Better More infrastructure program is generating substantial demand for conveyor systems across construction, cement production, and logistics applications. Sustained infrastructure spending maintained at significant levels relative to GDP is driving expansion of manufacturing facilities, transportation networks, and industrial zones requiring modern material handling equipment. Major cement producers are expanding production capacity to meet infrastructure demand, with local manufacturers investing in additional capacity over recent years. These infrastructure investments support construction of roads, bridges, railways, and ports requiring efficient material transport solutions throughout project execution phases.

E-commerce Growth and Logistics Sector Modernization

Rapid e-commerce expansion in the Philippines is driving significant investment in warehouse automation and logistics infrastructure requiring conveyor systems for efficient order fulfillment. The increasing number of online shoppers is compelling logistics providers to modernize facilities with automated material handling solutions improving sorting, packing, and shipping efficiency. The Philippines e-commerce market sales are estimated to reach approximately USD 24 Billion by 2025, according to the International Trade Administration, highlighting the substantial growth driving logistics infrastructure investment. Distribution centers serving major urban areas require sophisticated conveyor networks supporting omnichannel retail strategies and same-day delivery capabilities demanded by digital commerce growth.

Market Restraints:

What Challenges the Philippines Conveyor Belt Market is Facing?

High Dependence on Imported Components and Raw Materials

The Philippines conveyor belt market faces challenges from heavy reliance on imported components, raw materials, and finished conveyor systems. This dependence exposes the market to global price fluctuations, supply chain disruptions, and currency volatility affecting procurement costs. Limited local manufacturing infrastructure for specialized conveyor components constrains market development and increases lead times for equipment procurement and replacement parts.

High Capital Requirements and Maintenance Costs

Substantial capital requirements for conveyor system installation and ongoing maintenance expenses present barriers to market expansion, particularly among small and medium enterprises. High energy costs in the Philippines impact operational expenses for conveyor-intensive facilities, affecting return on investment calculations. These cost considerations may delay adoption of advanced conveyor technologies among price-sensitive industrial segments.

Technical Workforce Shortages and Skills Gaps

The lack of qualified technical workers for system installation, operation, and maintenance is a problem for the conveyor belt market in the Philippines. Shortage of technicians trained in automation, predictive maintenance, and industrial controls constrains adoption of advanced conveyor technologies. This skills gap necessitates intensive training investments and may result in suboptimal system performance affecting operational efficiency.

Philippines Conveyor Belt Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2025 |

| Historical Period | 2020-2025 |

| Forecast Period | 2026-2034 |

| Units | Million USD |

| Scope of the Report |

Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Types Covered | Medium-Weight Conveyor Belt, Light-Weight Conveyor Belt, Heavy-Weight Conveyor Belt |

| End Uses Covered | Mining and Metallurgy, Manufacturing, Chemicals, Oils and Gases, Aviation, Others |

| Regions Covered | Luzon, Visayas, Mindanao |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report

The Philippines conveyor belt market size was valued at USD 32.84 Million in 2025.

The Philippines conveyor belt market is expected to grow at a compound annual growth rate of 4.94% from 2026-2034 to reach USD 50.70 Million by 2034.

Medium-weight conveyor belt dominated the market with a 56.95% share in 2025, driven by widespread adoption across manufacturing, logistics, and food processing applications requiring moderate load capacity and operational flexibility suitable for diverse industrial environments.

Key factors driving the Philippines conveyor belt market include expanding mining operations and mineral processing investments, government infrastructure development programs under Build Better More, rapid e-commerce growth driving logistics automation, and increasing industrial automation adoption across manufacturing sectors.

Major challenges include high dependence on imported components and raw materials exposing the market to supply chain disruptions, substantial capital requirements for system installation and maintenance, high energy costs impacting operational expenses, and technical workforce shortages constraining adoption of advanced conveyor technologies.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)