Global Plating on Plastics Market Expected to Reach USD 1,367.9 Million by 2033 - IMARC Group

Global Plating on Plastics Market Statistics, Outlook and Regional Analysis 2025-2033

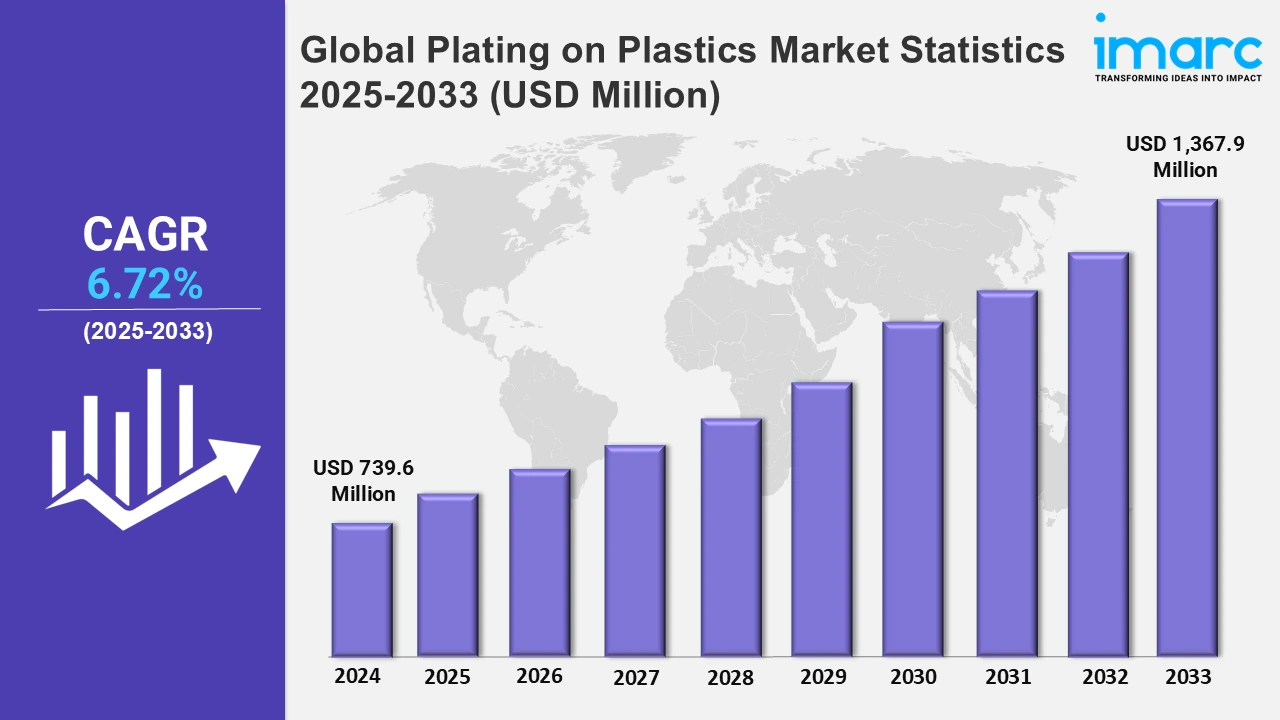

The global plating on plastics market size was valued at USD 739.6 Million in 2024, and it is expected to reach USD 1,367.9 Million by 2033, exhibiting a growth rate (CAGR) of 6.72% from 2025 to 2033.

To get more information on this market, Request Sample

The growing need for lightweight materials in different sectors like automotive and aerospace to improve fuel efficiency and reduce emissions is bolstering the market growth. Plated plastics offer a lightweight alternative to metals without sacrificing functionality or aesthetics. Besides this, metal-plated plastics provide a visually appealing metallic finish along with additional functional benefits such as improved wear resistance, electrical conductivity, and corrosion resistance. This makes them ideal for use in decorative as well as functional components in automotive, electronics, and consumer products. Moreover, innovations in plating technology are enhancing the quality and durability of metal-plated plastics, making them more attractive for a variety of applications. These advancements allow for better adhesion, more consistent metal deposition, and the ability to plate complex shapes effectively. In 2025, Metal Finishing Technologies (MFT) unveiled a cutting-edge automated Zinc/Zinc Nickel production line, providing enhanced plating solutions for sectors such as aerospace, automotive, and manufacturing. The new line improves plating uniformity, boosts efficiency, and offers an environment-friendly substitute for cadmium plating.

Furthermore, the growing toward miniaturization in electronics, including smaller and more compact connectors, sensors, and circuit boards, is catalyzing the demand for plating on plastics. Plating on plastics enables manufacturers to produce small, high-performance components that are lightweight and cost-effective. In addition, strategic acquisitions and partnerships play a critical role in enhancing the capabilities and market reach of companies in the plating on plastics industry. By merging with or acquiring specialized firms, companies can leverage existing expertise and infrastructure to accelerate innovation and expand their service offerings across various industries. This strategy also facilitates access to new markets and user segments. In 2024, BEP Surface Technologies purchased Plating Solutions, a consultancy focused on metal finishing and plating, to bolster its innovation and growth strategy. The acquisition enhances BEP's ability to serve various sectors such as plastics, energy, and defense, capitalizing on the knowledge of Plating Solutions' founder, John Torr. This action is in line with BEP's larger objectives, such as promoting international R&D collaborations and innovations in surface coatings.

Global Plating on Plastics Market Statistics, By Region

The market research report has also provided a comprehensive analysis of all the major regional markets, which include North America (the United States and Canada); Asia-Pacific (China, Japan, India, South Korea, Australia, Indonesia, and others); Europe (Germany, France, the United Kingdom, Italy, Spain, Russia, and others); Latin America (Brazil, Mexico, and others); and the Middle East and Africa. According to the report, Europe accounted for the largest market share due to advanced manufacturing capabilities, strong automotive and electronics sectors, and increasing demand for sustainable, high-performance materials.

North America Plating on Plastics Market Trends:

In North America, the plating on plastics market is driven by a focus on technological innovation and high-quality manufacturing practices. The market benefits from the presence of established research institutions and leading industry players who invest heavily in R&D activities. This fosters the development of new and improved plating processes that enhance the performance and appeal of plastic components.

Asia-Pacific Plating on Plastics Market Trends:

Asia Pacific is a crucial segment in the market, primarily driven by significant advancements in manufacturing technologies and a robust electronics sector. The region's commitment to innovative materials science and technology accelerates the adoption of sophisticated plating techniques. This is further supported by strong regional growth in sectors that extensively use plated plastics, complemented by a focus on enhancing product features like durability and aesthetic appeal.

Europe Plating on Plastics Market Trends:

Europe dominates the market, characterized by stringent environmental regulations that encourage the development of eco-friendly plating alternatives. European manufacturers prioritize sustainability and high-quality standards, which propels the adoption of advanced plating technologies. This approach ensures that products meet the high user and regulatory expectations prevalent across the market. Additionally, the emphasis on innovation and environmental stewardship drives continuous improvements in plating processes, reducing environmental impact while enhancing product functionality. In 2024, Hansgrohe Group launched an advanced recycling technology at its Offenburg facility in collaboration with ImpulsTec, focusing on recycling chrome-plated ABS plastics. The process utilizes electro-hydraulic shredding to recover metals and decoated ABS, integrating recycled materials back into production. This initiative underscores Hansgrohe's commitment to sustainability and circular economy principles.

Latin America Plating on Plastics Market Trends:

Latin America's plating on plastics market is growing, with an increasing focus on improving manufacturing capabilities and technology penetration. The region is gradually embracing modern industrial techniques, which include the adoption of efficient and high-standard plating processes. This development is anticipated to enhance the quality and competitiveness of local products in the global market.

Middle East and Africa Plating on Plastics Market Trends:

The Middle East and Africa are experiencing a steady rise in the use of plating on plastics, fueled by initiatives to diversify industrial operations and improve manufacturing standards. This area's market gains from investments in infrastructure and technological progress, which are crucial for fostering the expansion of advanced manufacturing industries, including those that use plated plastics.

Top Companies Leading in the Plating on Plastics Industry

Some of the leading plating on plastics market companies include Artcraft Plating and Finishing Company Inc., Atotech, Bolta Werke GmbH, Cybershield Inc., DuPont de Nemours Inc., Galva Decoparts Pvt. Ltd., JCU Corporation, Leader Plating on Plastic Ltd, MacDermid Incorporated (Element Solutions Inc), MPC Plating Inc., Phillips Plating Corporation, and Precision Plating (Aust) Pty Ltd., among many others. In 2024, SABIC revealed a collaboration with Cybershield Inc. to advance the use of plated ULTEM™ resins in aerospace applications, focusing on electroless plating for EMI shielding. This initiative aims to enhance molding capabilities and plating quality for high-heat ULTEM resins, with applications in aviation, automotive, and electronics.

Global Plating on Plastics Market Segmentation Coverage

- On the basis of the plastic type, the market has been categorized into ABS, ABS/PC, PEI, PBT, LCP, PEEK, PP, and others, wherein ABS represent the leading segment. ABS dominates the market due to its excellent properties like rigidity, high impact resistance, and thermal stability. This makes ABS ideal for automotive, electronics, and household applications where durability and aesthetics are crucial. The ability of ABS to adhere well with metallic coatings also enhances its desirability for electroplating, making it a preferred choice for manufacturers seeking high-quality finishes on plastic components.

- Based on the plating type, the market is classified into chrome, nickel, and others, amongst which chrome dominates the market. Chrome plating is favored for its superior aesthetic appeal and corrosion resistance. This finish is particularly popular in the automotive and bathroom fittings industries, where it is used to provide a sleek, mirror-like finish that is both durable and visually striking. Chrome's ability to resist tarnishing and wear under various environmental conditions also contributes significantly to its widespread use and market dominance.

- On the basis of the application, the market has been divided into automotive, building and construction, utilities, electronics, and others. Among these, automotive accounts for the majority of the market share. This dominance can be attributed to the industry's need for durable, lightweight, and aesthetically pleasing components. Chrome and nickel-plated plastics are extensively used in automotive interiors and exteriors for features such as grilles, emblems, and trim parts, enhancing both functionality and style. The trend towards more luxurious and customized vehicle interiors continues to propel the demand for high-quality plated plastics in this sector.

| Report Features | Details |

|---|---|

| Market Size in 2024 | USD 739.6 Million |

| Market Forecast in 2033 | USD 1,367.9 Million |

| Market Growth Rate 2025-2033 | 6.72% |

| Units | Million USD |

| Scope of the Report | Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Plastic Types Covered | ABS, ABS/PC, PEI, PBT, LCP, PEEK, PP, Others |

| Plating Types Covered | Chrome, Nickle, Others |

| Applications Covered | Automotive, Building and Construction, Utilities, Electronics, Others |

| Regions Covered | Asia Pacific, Europe, North America, Latin America, Middle East and Africa |

| Countries Covered | United States, Canada, Germany, France, United Kingdom, Italy, Spain, Russia, China, Japan, India, South Korea, Australia, Indonesia, Brazil, Mexico |

| Companies Covered | Artcraft Plating and Finishing Company Inc., Atotech, Bolta Werke GmbH, Cybershield Inc., DuPont de Nemours Inc., Galva Decoparts Pvt. Ltd., JCU Corporation, Leader Plating on Plastic Ltd, MacDermid Incorporated (Element Solutions Inc), MPC Plating Inc., Phillips Plating Corporation, Precision Plating (Aust) Pty Ltd., etc. |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Inquire Before Buying

Inquire Before Buying

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

.webp)

.webp)