Saudi Arabia Die Casting Components Market Size, Share, Trends and Forecast by Component Type, Material Type, Process Type, Sales Channel, End Use Industry, and Region, 2026-2034

Saudi Arabia Die Casting Components Market Overview:

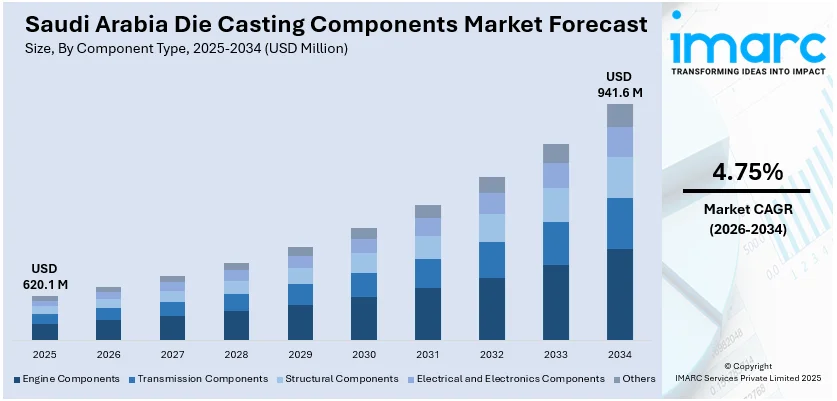

The Saudi Arabia die casting components market size reached USD 620.1 Million in 2025. Looking forward, IMARC Group expects the market to reach USD 941.6 Million by 2034, exhibiting a growth rate (CAGR) of 4.75% during 2026-2034. The growing investments in infrastructure projects, including roads, bridges, and buildings, are creating the need for die casting components in construction tools, safety equipment, and fixtures. Besides this, the increasing focus on producing electric vehicles (EVs) and internal combustion engine (ICE) vehicles to improve fuel efficiency and performance is contributing to the expansion of the Saudi Arabia die casting components market share.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2025 |

|

Forecast Years

|

2026-2034

|

|

Historical Years

|

2020-2025

|

| Market Size in 2025 | USD 620.1 Million |

| Market Forecast in 2034 | USD 941.6 Million |

| Market Growth Rate 2026-2034 | 4.75% |

Saudi Arabia Die Casting Components Market Trends:

Increasing vehicle production

Rising vehicle production is positively influencing the market in Saudi Arabia. According to industry reports, by 2025, the country plans to manufacture more than 300,000 vehicles, generating over 27,000 jobs in the sector. As vehicle production is growing, manufacturers are demanding components, such as engine blocks, transmission cases, and structural parts, which are developed using die casting methods. Die casting provides benefits like accuracy, intricate shapes, and rapid manufacturing rates, making it suitable for automotive uses. As manufacturers are focusing on producing ICE vehicles and EVs, they persist in utilizing die casting to manufacture components that enhance fuel efficiency and performance, particularly in lightweight automobiles. The increase in vehicle manufacturing is promoting the usage of materials, such as aluminum and magnesium, which are both lightweight and durable, to lower the total weight of vehicles and improve fuel efficiency. Saudi Arabia’s thriving automotive industry, supported by governmental efforts to diversify its economy and develop the manufacturing sector, is contributing to the increased demand for die-cast components. As vehicle production is increasing, the need for cost-effective and high-performance parts is promoting the employment of die casting components, positioning it as a key sector in the country’s burgeoning automotive industry.

To get more information on this market Request Sample

Rising construction activities

Increasing construction activities are impelling the Saudi Arabia die casting components market growth. In 2024, the construction sector in Saudi Arabia was projected to expand by 4.6%. As the construction industry is thriving in the country, equipment like cranes, excavators, and bulldozers require die-cast components, such as engine parts, housings, and structural elements. Die casting allows manufacturers to produce complex, precise, and lightweight components that are essential for the durability and efficiency of construction machinery. Additionally, the rise in infrastructure projects, including roads, bridges, and buildings, is creating the need for die-cast metal components in construction tools, safety equipment, and fixtures. As the construction activities are expanding, the demand for die casting components is increasing, supporting the market growth in Saudi Arabia.

Growing demand for electronic items

Increasing demand for electronic items is propelling the market growth. Many electronic products, such as smartphones, laptops, and home appliances, require die-cast components for parts like housings, frames, and connectors. Die casting allows the manufacturing of lightweight, durable, and heat-resistant parts that are essential for the performance and longevity of electronic devices. As the demand for electronics continues to rise, manufacturers are increasingly relying on die-casting techniques to meet production requirements. Moreover, the expansion of e-commerce sites is enhancing the accessibility and sales of electronic items, thereby promoting the utilization of die casting components. As per industry reports, the Saudi Arabian electronics e-commerce market is set to attain USD 3,341.3 Million by 2025.

Saudi Arabia Die Casting Components Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the country and regional levels for 2026-2034. Our report has categorized the market based on component type, material type, process type, sales channel, and end use industry.

Component Type Insights:

- Engine Components

- Transmission Components

- Structural Components

- Electrical and Electronics Components

- Others

The report has provided a detailed breakup and analysis of the market based on the component type. This includes engine components, transmission components, structural components, electrical and electronics components, and others.

Material Type Insights:

- Aluminum Die Castings

- Zinc Die Castings

- Magnesium Die Castings

- Others

A detailed breakup and analysis of the market based on the material type have also been provided in the report. This includes aluminum die castings, zinc die castings, magnesium die castings, and others.

Process Type Insights:

- High-Pressure Die Casting (HPDC)

- Low-Pressure Die Casting (LPDC)

- Gravity Die Casting

- Others

The report has provided a detailed breakup and analysis of the market based on the process type. This includes high-pressure die casting (HPDC), low-pressure die casting (LPDC), gravity die casting, and others.

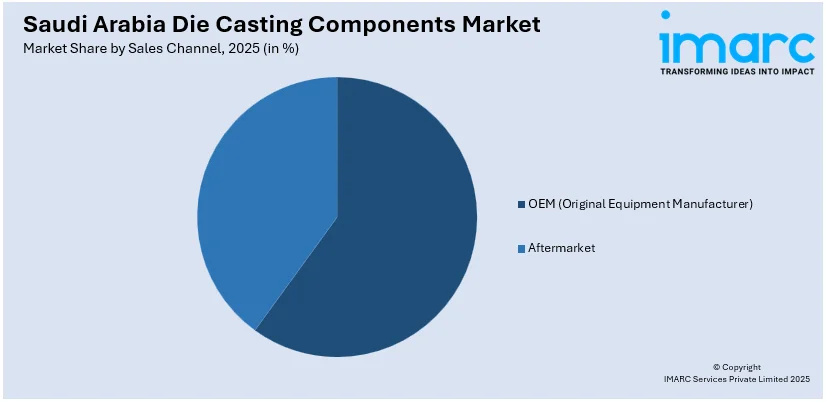

Sales Channel Insights:

Access the comprehensive market breakdown Request Sample

- OEM (Original Equipment Manufacturer)

- Aftermarket

A detailed breakup and analysis of the market based on the sales channel have also been provided in the report. This includes OEM (original equipment manufacturer) and aftermarket.

End Use Industry Insights:

- Automotive

- Aerospace and Defense

- Industrial Machinery

- Electrical and Electronics

- Consumer Goods

- Others

The report has provided a detailed breakup and analysis of the market based on the end use industry. This includes automotive, aerospace and defense, industrial machinery, electrical and electronics, consumer goods, and others.

Regional Insights:

- Northern and Central Region

- Western Region

- Eastern Region

- Southern Region

The report has also provided a comprehensive analysis of all the major regional markets, which include Northern and Central Region, Western Region, Eastern Region, and Southern Region.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

Saudi Arabia Die Casting Components Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2025 |

| Historical Period | 2020-2025 |

| Forecast Period | 2026-2034 |

| Units | Million USD |

| Scope of the Report | Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Component Types Covered | Engine Components, Transmission Components, Structural Components, Electrical and Electronics Components, Others |

| Material Types Covered | Aluminum Die Castings, Zinc Die Castings, Magnesium Die Castings, Others |

| Process Types Covered | High-Pressure Die Casting (HPDC), Low-Pressure Die Casting (LPDC), Gravity Die Casting, Others |

| Sales Channels Covered | OEM (Original Equipment Manufacturer), Aftermarket |

| End Use Industries Covered | Automotive, Aerospace and Defense, Industrial Machinery, Electrical and Electronics, Consumer Goods, Others |

| Regions Covered | Northern and Central Region, Western Region, Eastern Region, Southern Region |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the Saudi Arabia die casting components market performed so far and how will it perform in the coming years?

- What is the breakup of the Saudi Arabia die casting components market on the basis of component type?

- What is the breakup of the Saudi Arabia die casting components market on the basis of material type?

- What is the breakup of the Saudi Arabia die casting components market on the basis of process type?

- What is the breakup of the Saudi Arabia die casting components market on the basis of sales channel?

- What is the breakup of the Saudi Arabia die casting components market on the basis of end use industry?

- What is the breakup of the Saudi Arabia die casting components market on the basis of region?

- What are the various stages in the value chain of the Saudi Arabia die casting components market?

- What are the key driving factors and challenges in the Saudi Arabia die casting components market?

- What is the structure of the Saudi Arabia die casting components market and who are the key players?

- What is the degree of competition in the Saudi Arabia die casting components market?

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the Saudi Arabia die casting components market from 2020-2034.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the Saudi Arabia die casting components market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the Saudi Arabia die casting components industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)