Saudi Arabia Smart Welding Equipment Market Size, Share, Trends and Forecast by Component, Material Type, Welding Technology, Automation Level, End Use Industry, and Region, 2026-2034

Saudi Arabia Smart Welding Equipment Market Overview:

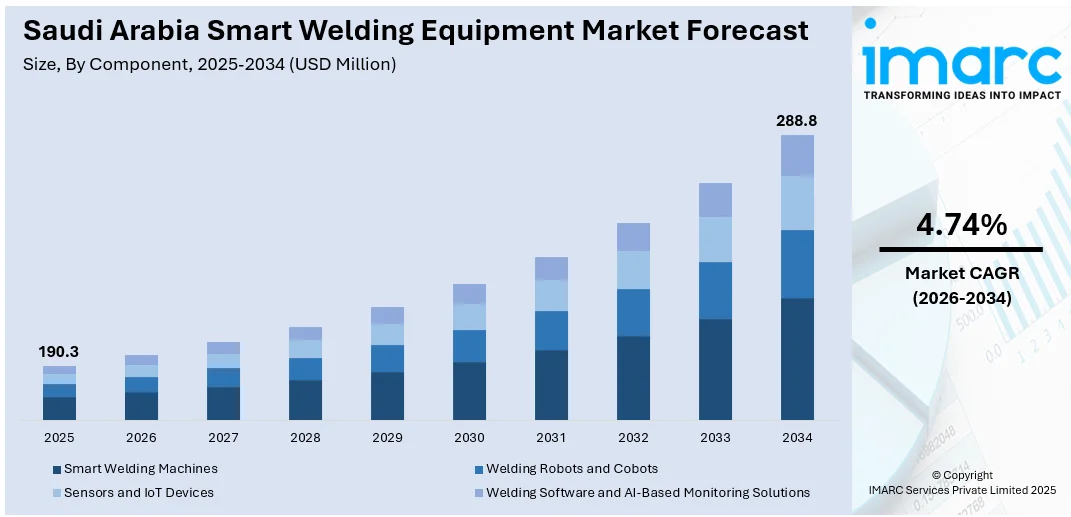

The Saudi Arabia smart welding equipment market size reached USD 190.3 Million in 2025. Looking forward, IMARC Group expects the market to reach USD 288.8 Million by 2034, exhibiting a growth rate (CAGR) of 4.74% during 2026-2034. The market is experiencing steady growth due to industrial diversification, rising automation in manufacturing, and increased infrastructure development driven by national transformation goals. Demand for precision, efficiency, and safety encourages the adoption of advanced welding technologies across sectors like oil and gas, construction, and automotive, thereby reshaping the Saudi Arabia smart welding equipment market share.

|

Report Attribute

|

Key Statistics

|

|---|---|

|

Base Year

|

2025

|

|

Forecast Years

|

2026-2034

|

|

Historical Years

|

2020-2025

|

| Market Size in 2025 | USD 190.3 Million |

| Market Forecast in 2034 | USD 288.8 Million |

| Market Growth Rate 2026-2034 | 4.74% |

Saudi Arabia Smart Welding Equipment Market Trends:

Industrial Diversification under Vision 2030

Saudi Arabia’s Vision 2030 initiative aims to diversify the economy beyond oil, fostering growth in sectors like manufacturing, mining, construction, and logistics. This change is fostering the use of smart technologies in the industry, such as welding equipment that enhances industrial needs. Due to the development of new factories and industrial cities and industrial cities as well as mega-projects added welding solutions have been added that can guarantee accurate, fast, and optimal results. Automated welding systems and digital controls included in such smart welding systems help the government in its move towards the modernization of technology. This structural change is driving a firm demand for high-performance welding tools that underpin industrial productivity and growth trajectories, making smart welding equipment an essential enabler of KSA’s ongoing industrialization.

To get more information on this market Request Sample

Growth in Construction and Infrastructure Projects

Saudi Arabia’s booming construction sector, fueled by mega-projects like NEOM, the Red Sea Project, and the Riyadh Metro, is a major catalyst for smart welding equipment adoption. These projects require high-quality, large-scale welding solutions for steel frameworks, pipelines, and structural components, which is driving the Saudi Arabia smart welding equipment market growth. Smart welding systems enhance productivity, minimize errors, and improve safety on complex construction sites. With strict timelines and quality benchmarks, construction firms are increasingly turning to automated and intelligent welding solutions to maintain efficiency. The demand for precision and speed in infrastructure development fuels the growth of smart welding technologies, making them a vital part of modern construction workflows across the country’s rapidly evolving urban and industrial landscapes.

Automation and Digitalization in the Oil and Gas Sector

The oil and gas industry in Saudi Arabia, though mature, is undergoing major modernization through automation and digital transformation. Smart welding equipment plays a pivotal role in this transition by enabling safer, faster, and more accurate pipeline welding, structural repairs, and equipment fabrication. These systems offer real-time monitoring, predictive maintenance, and integration with robotic arms, enhancing operational efficiency in hazardous environments. As companies strive to reduce downtime and improve worker safety, they increasingly invest in intelligent welding solutions. This is especially crucial in remote or offshore applications where consistency and control are critical. The sector’s shift toward smarter technologies makes it a key driver of demand for advanced welding systems in the kingdom.

Saudi Arabia Smart Welding Equipment Market Segmentation:

IMARC Group provides an analysis of the key trends in each segment of the market, along with forecasts at the country and regional levels for 2026-2034. Our report has categorized the market based on component, material type, welding technology, automation level, and end use industry.

Component Insights:

- Smart Welding Machines

- Welding Robots and Cobots

- Sensors and IoT Devices

- Welding Software and AI-Based Monitoring Solutions

The report has provided a detailed breakup and analysis of the market based on the component. This includes smart welding machines, welding robots and cobots, sensors and IoT devices, and welding software and AI-based monitoring solutions.

Material Type Insights:

- Steel and Stainless Steel Welding

- Aluminum and Non-Ferrous Metal Welding

- Composite and Advanced Material Welding

A detailed breakup and analysis of the market based on the material type have also been provided in the report. This includes steel and stainless steel welding, aluminum and non-ferrous metal welding, and composite and advanced material welding.

Welding Technology Insights:

- Arc Welding

- Resistance Welding

- Laser Welding

- Electron Beam Welding

- Ultrasonic Welding

- Friction Stir Welding

- Plasma Welding

A detailed breakup and analysis of the market based on the welding technology have also been provided in the report. This includes arc welding, resistance welding, laser welding, electron beam welding, ultrasonic welding, friction stir welding, and plasma welding.

Automation Level Insights:

- Manual Welding Equipment

- Semi-Automated Welding Systems

- Fully Automated and AI-Integrated Welding Systems

A detailed breakup and analysis of the market based on the automation level have also been provided in the report. This includes manual welding equipment, semi-automated welding systems, and fully automated and AI-integrated welding systems.

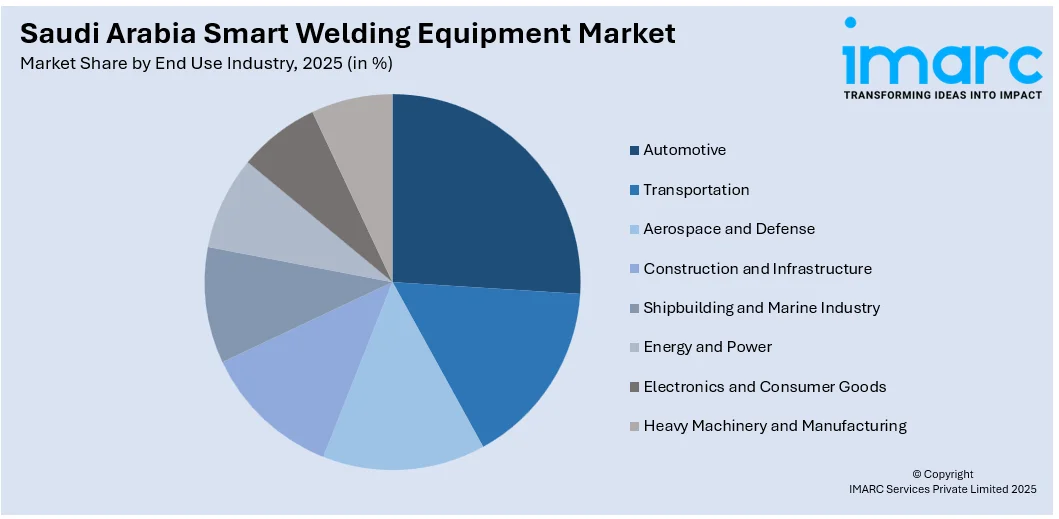

End Use Industry Insights:

Access the comprehensive market breakdown Request Sample

- Automotive

- Transportation

- Aerospace and Defense

- Construction and Infrastructure

- Shipbuilding and Marine Industry

- Energy and Power

- Electronics and Consumer Goods

- Heavy Machinery and Manufacturing

A detailed breakup and analysis of the market based on the end use industry have also been provided in the report. This includes automotive, transportation, aerospace and defense, construction and infrastructure, shipbuilding and marine industry, energy and power, electronics and consumer goods, and heavy machinery and manufacturing.

Regional Insights:

- Northern and Central Region

- Western Region

- Eastern Region

- Southern Region

The report has also provided a comprehensive analysis of all the major regional markets, which include the Northern and Central Region, Western Region, Eastern Region, and Southern Region.

Competitive Landscape:

The market research report has also provided a comprehensive analysis of the competitive landscape. Competitive analysis such as market structure, key player positioning, top winning strategies, competitive dashboard, and company evaluation quadrant has been covered in the report. Also, detailed profiles of all major companies have been provided.

Saudi Arabia Smart Welding Equipment Market Report Coverage:

| Report Features | Details |

|---|---|

| Base Year of the Analysis | 2025 |

| Historical Period | 2020-2025 |

| Forecast Period | 2026-2034 |

| Units | Million USD |

| Scope of the Report |

Exploration of Historical Trends and Market Outlook, Industry Catalysts and Challenges, Segment-Wise Historical and Future Market Assessment:

|

| Components Covered | Smart Welding Machines, Welding Robots and Cobots, Sensors and IoT Devices, Welding Software and AI-Based Monitoring Solutions |

| Material Types Covered | Steel and Stainless Steel Welding, Aluminum and Non-Ferrous Metal Welding, Composite and Advanced Material Welding |

| Welding Technologies Covered | Arc Welding, Resistance Welding, Laser Welding, Electron Beam Welding, Ultrasonic Welding, Friction Stir Welding, Plasma Welding |

| Automation Levels Covered | Manual Welding Equipment, Semi-Automated Welding Systems, Fully Automated and AI-Integrated Welding Systems |

| End Use Industries Covered | Automotive, Transportation, Aerospace and Defense, Construction and Infrastructure, Shipbuilding and Marine Industry, Energy and Power, Electronics and Consumer Goods, Heavy Machinery and Manufacturing |

| Regions Covered | Northern and Central Region, Western Region, Eastern Region, Southern Region |

| Customization Scope | 10% Free Customization |

| Post-Sale Analyst Support | 10-12 Weeks |

| Delivery Format | PDF and Excel through Email (We can also provide the editable version of the report in PPT/Word format on special request) |

Key Questions Answered in This Report:

- How has the Saudi Arabia smart welding equipment market performed so far and how will it perform in the coming years?

- What is the breakup of the Saudi Arabia smart welding equipment market on the basis of component?

- What is the breakup of the Saudi Arabia smart welding equipment market on the basis of material type?

- What is the breakup of the Saudi Arabia smart welding equipment market on the basis of welding technology?

- What is the breakup of the Saudi Arabia smart welding equipment market on the basis of automation level?

- What is the breakup of the Saudi Arabia smart welding equipment market on the basis of end use industry?

- What is the breakup of the Saudi Arabia smart welding equipment market on the basis of region?

- What are the various stages in the value chain of the Saudi Arabia smart welding equipment market?

- What are the key driving factors and challenges in the Saudi Arabia smart welding equipment?

- What is the structure of the Saudi Arabia smart welding equipment market and who are the key players?

- What is the degree of competition in the Saudi Arabia smart welding equipment market?

Key Benefits for Stakeholders:

- IMARC’s industry report offers a comprehensive quantitative analysis of various market segments, historical and current market trends, market forecasts, and dynamics of the Saudi Arabia smart welding equipment market from 2020-2034.

- The research report provides the latest information on the market drivers, challenges, and opportunities in the Saudi Arabia smart welding equipment market.

- Porter's five forces analysis assist stakeholders in assessing the impact of new entrants, competitive rivalry, supplier power, buyer power, and the threat of substitution. It helps stakeholders to analyze the level of competition within the Saudi Arabia smart welding equipment industry and its attractiveness.

- Competitive landscape allows stakeholders to understand their competitive environment and provides an insight into the current positions of key players in the market.

Need more help?

- Speak to our experienced analysts for insights on the current market scenarios.

- Include additional segments and countries to customize the report as per your requirement.

- Gain an unparalleled competitive advantage in your domain by understanding how to utilize the report and positively impacting your operations and revenue.

- For further assistance, please connect with our analysts.

Request Customization

Request Customization

Speak to an Analyst

Speak to an Analyst

Request Brochure

Request Brochure

Inquire Before Buying

Inquire Before Buying

.webp)

.webp)